Self-cleaning nozzle

A self-cleaning and nozzle technology, applied in the direction of spraying device, spraying device, liquid spraying device, etc., can solve the problem of easy clogging of nozzles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

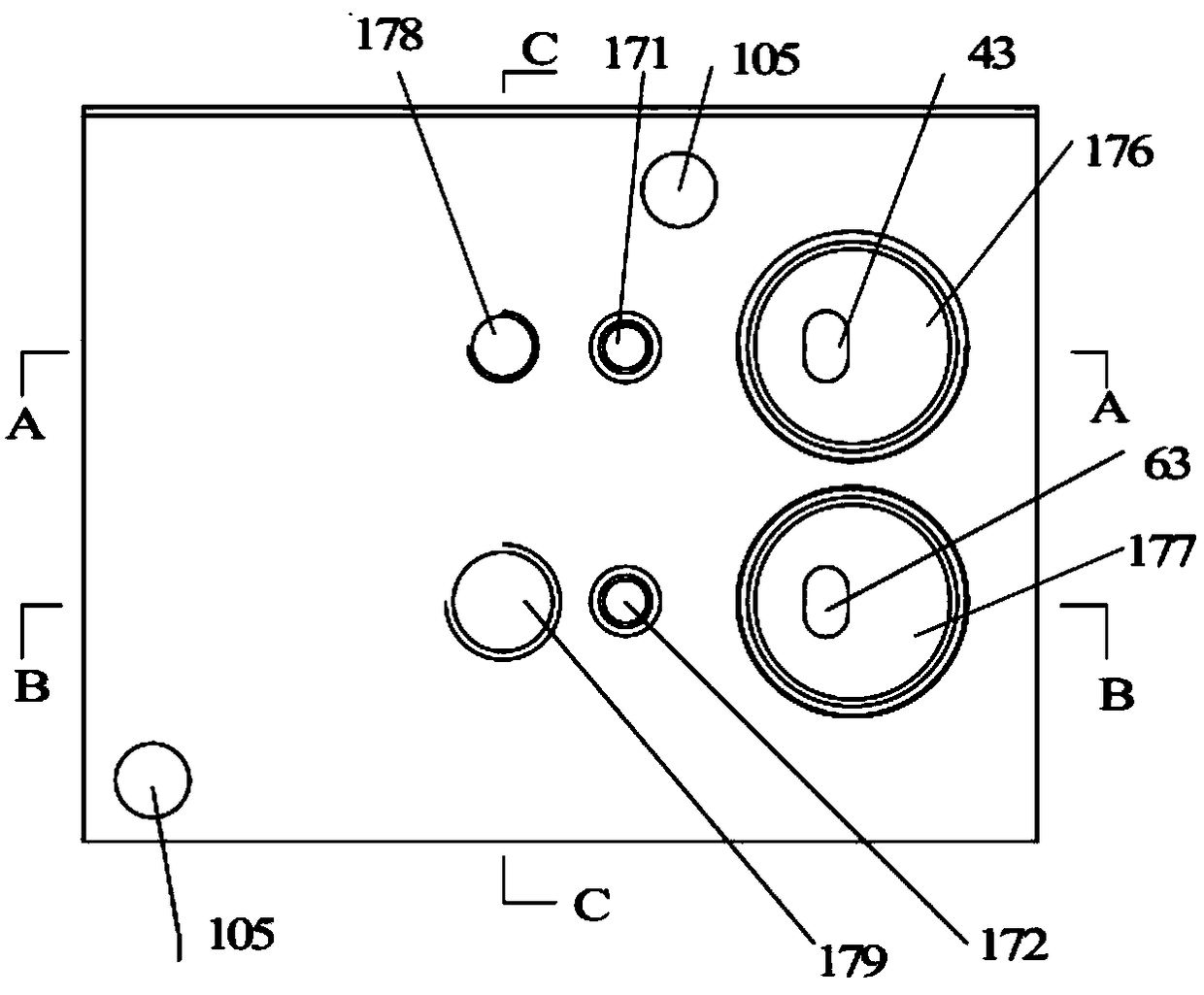

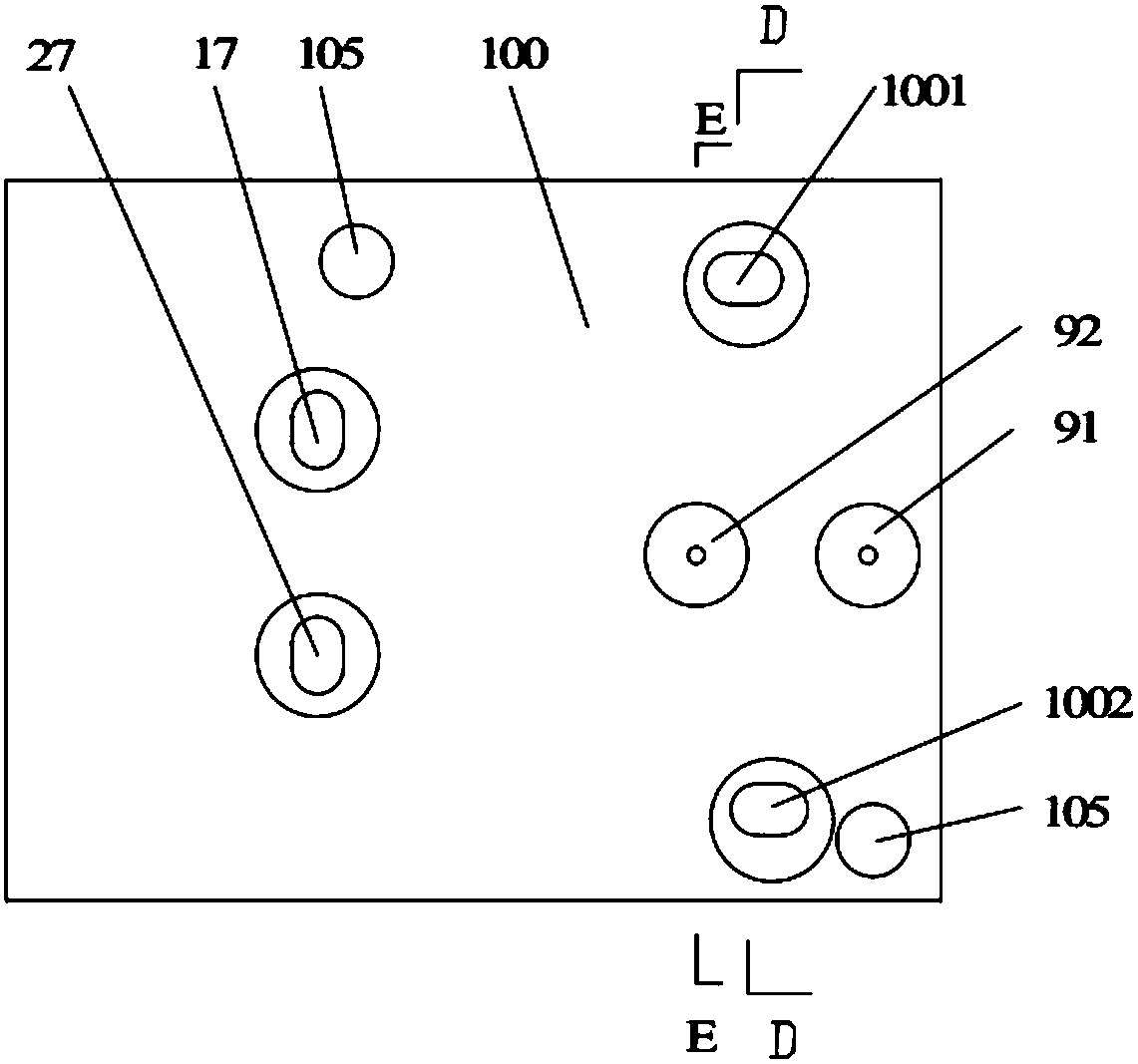

[0096] The present invention provides a self-cleaning nozzle. The nozzle includes a nozzle body 100, an attached nozzle body 200, a water outlet pipeline and a nozzle head. The water outlet pipeline includes a working pipeline 101 and a sewage pipeline 102. The nozzle head includes The working nozzle head 103 and the sewage nozzle head 104 ; the nozzle body 100 communicates with the working nozzle head 103 through the working pipeline 101 , and the attached nozzle body 200 communicates with the sewage nozzle head 104 through the sewage pipeline 102 .

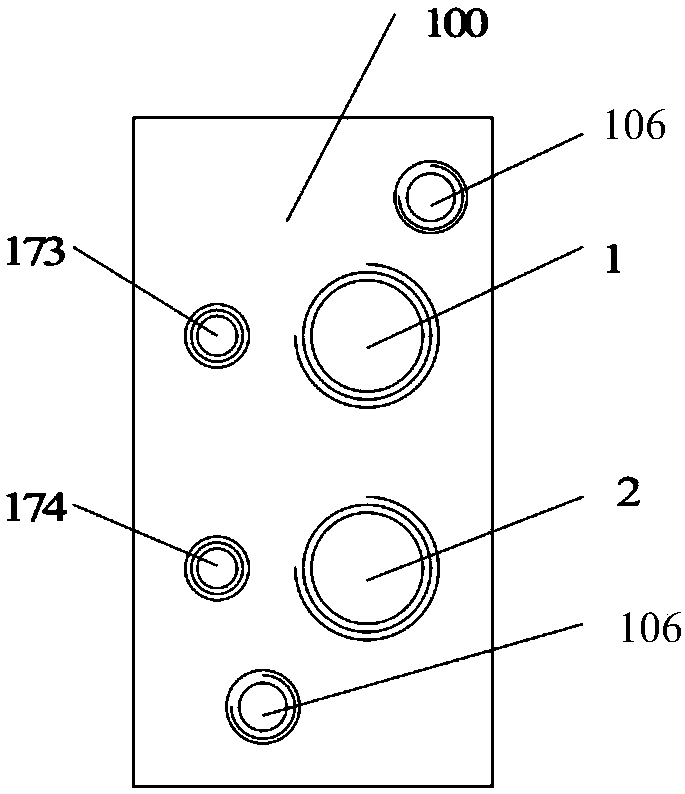

[0097] The nozzle body 100 includes a first channel 1, a second channel 2, a third channel 3, a first filter channel 4, an air outlet channel 5 of the first channel, a second filter channel 6 and a water outlet channel 7 of the second channel; The two ends of the first filter channel 4 communicate with the first channel 1 respectively, and the air outlet channel 5 of the first channel communicates with the first channel 1 and the...

Embodiment 2

[0140] Different from the nozzle shown in Embodiment 1, the nozzle provided in this embodiment does not include an attached nozzle body. The nozzle provided in this embodiment includes a nozzle body, a water outlet pipeline and a nozzle head, and a fourth channel is arranged in the nozzle body; The cleaning exhaust port and the cleaning drain port are respectively connected with the fourth channel; the water outlet pipeline includes a working pipeline and a sewage pipeline, and the nozzle head includes a working nozzle head and a sewage nozzle head; the third channel The working pipeline communicates with the working nozzle head, and the fourth channel communicates with the sewage nozzle head through the sewage pipeline.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com