Electric variable-speed variable-pitch linear reciprocating constant-temperature device

A constant temperature device, reciprocating technology, applied in the direction of electromechanical devices, electric components, electrical components, etc., can solve the problems of unstable output and weak power, and achieve the effect of strong output power, convenient and efficient use, and stable work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

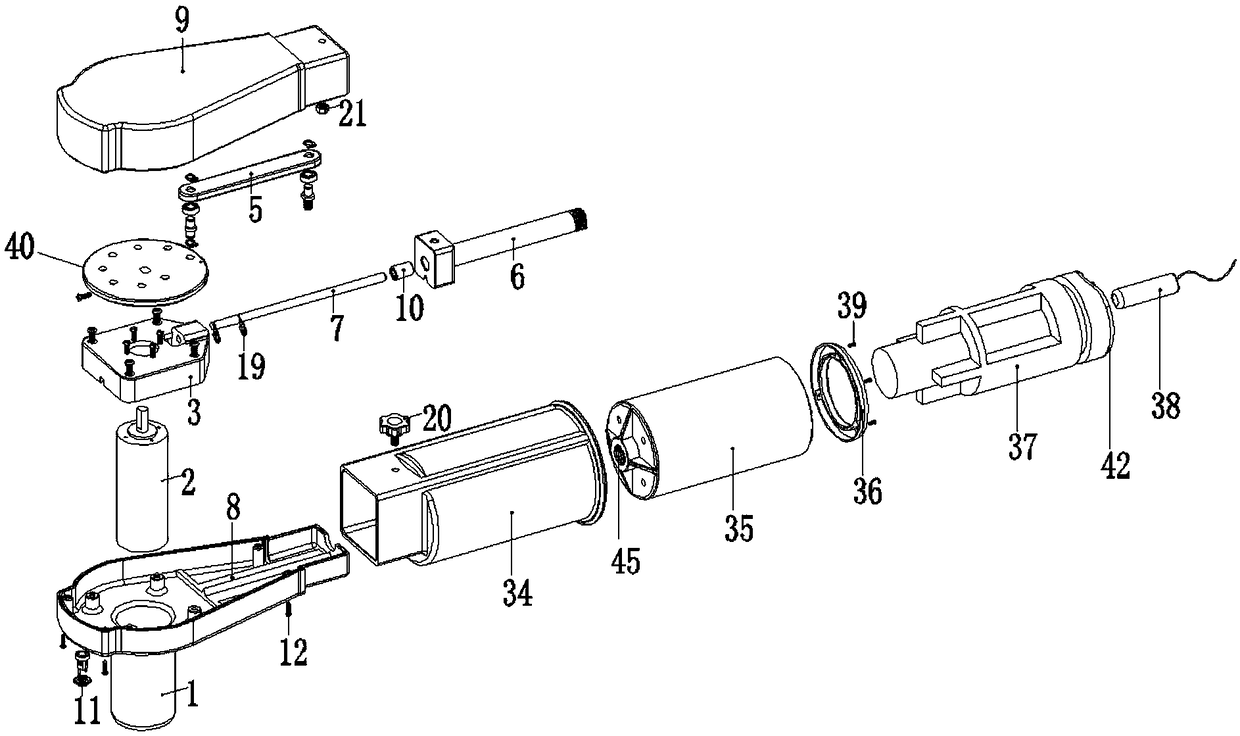

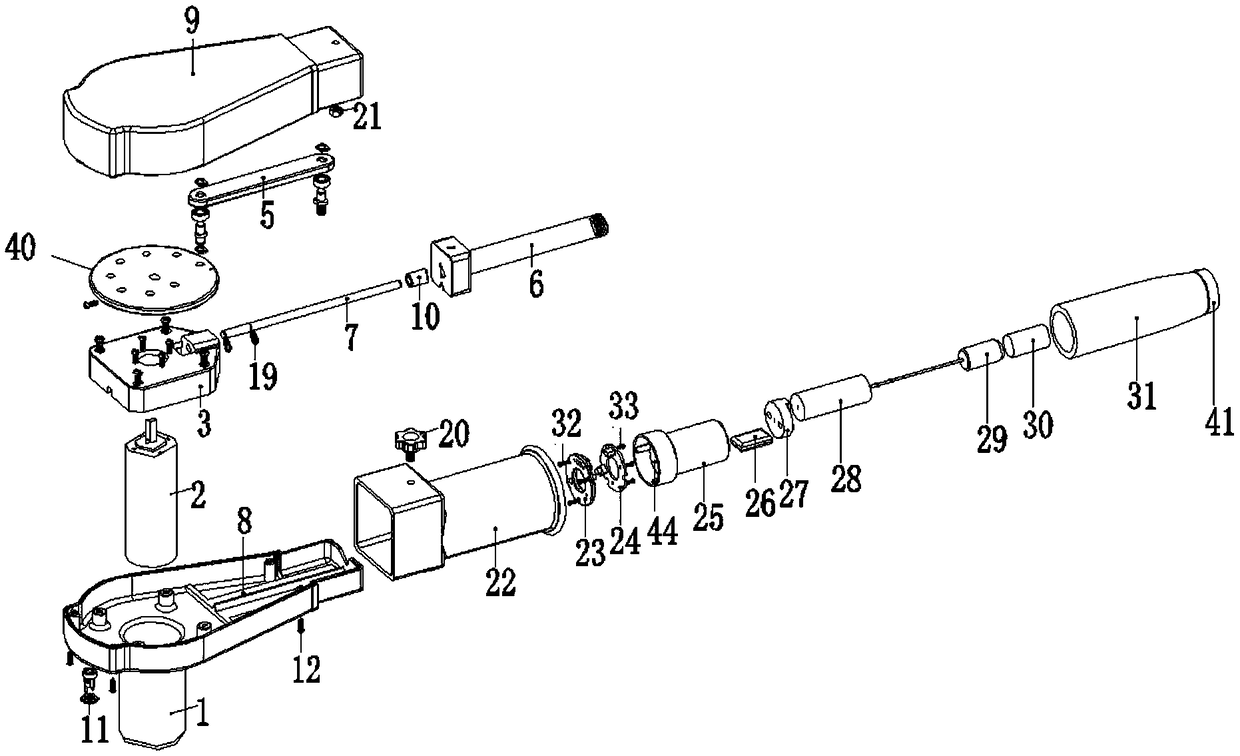

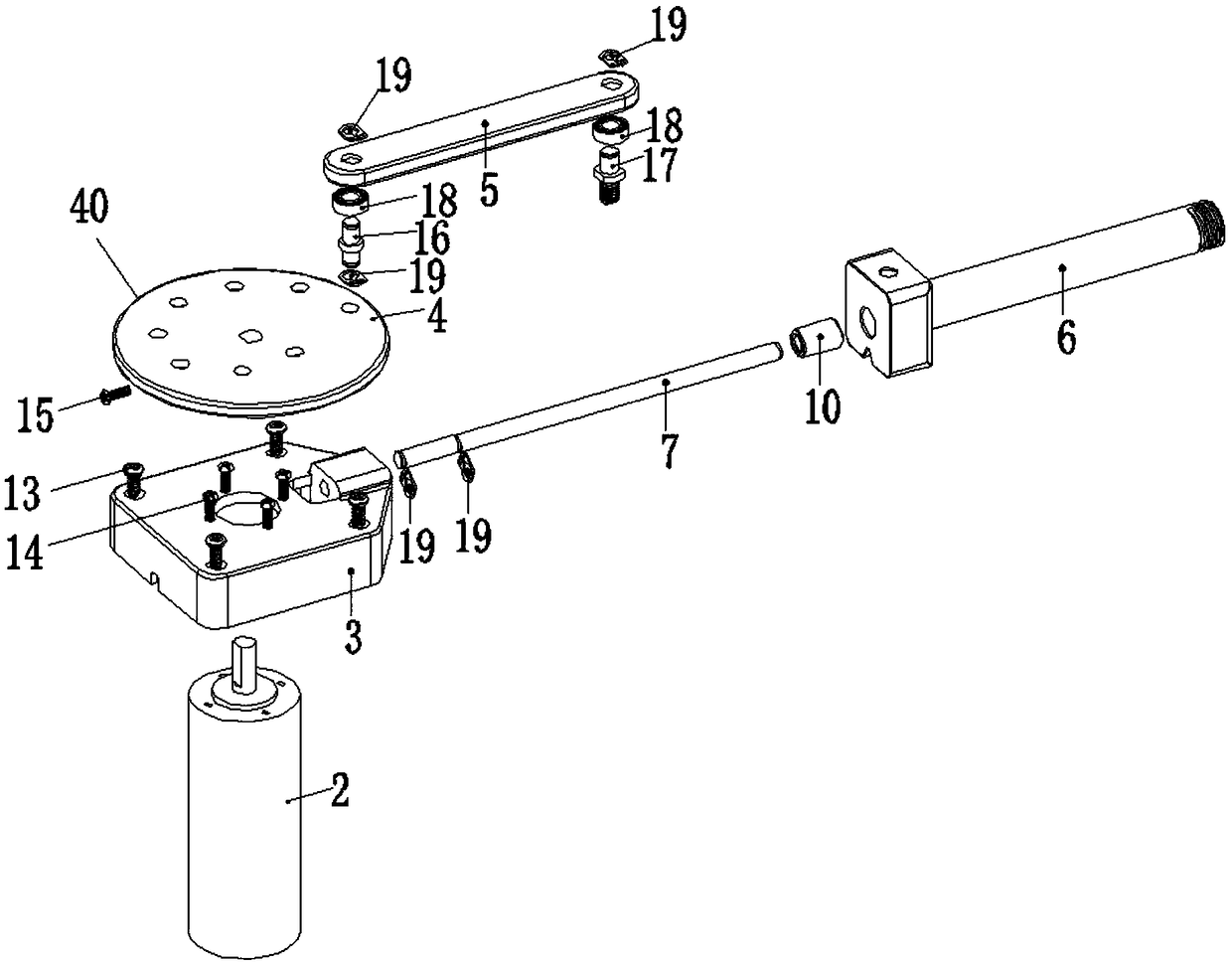

[0041] The present invention provides such Figure 1-21A linear reciprocating constant temperature device with electric variable speed and variable distance shown includes a fuselage base 1, a drive mechanism 40, a latex rod body 41 and a latex sleeve 42, and the top of the fuselage base 1 is fixed by fixing screws 12 up and down the fuselage There is an upper cover 9, the bottom of the fuselage base 1 is provided with a power inlet 11, the inner side of the fuselage base 1 is provided with a slider lower guide rail 8, and the driving mechanism 40 includes a motor 2, a motor fixing base 3, Connecting rod 5, slider 6, round bar guide rail 7, bushing 10, motor fixing seat locking screw 13, motor fixing screw 14, crank disc fixing screw 15, first rotating shaft 16, second rotating shaft 17 and connecting bearing 18 and the positioning shaft with a jumper 19, the motor fixing base 3 is installed on the inner plane of the fuselage base 1 through the motor fixing base locking screw ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com