A one-dimensional pneumatic design method for a helium compressor

A design method and compressor technology, applied in the directions of calculation, instrument, geometric CAD, etc., can solve the problem of not being able to meet the efficiency requirements of helium compressors, and achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

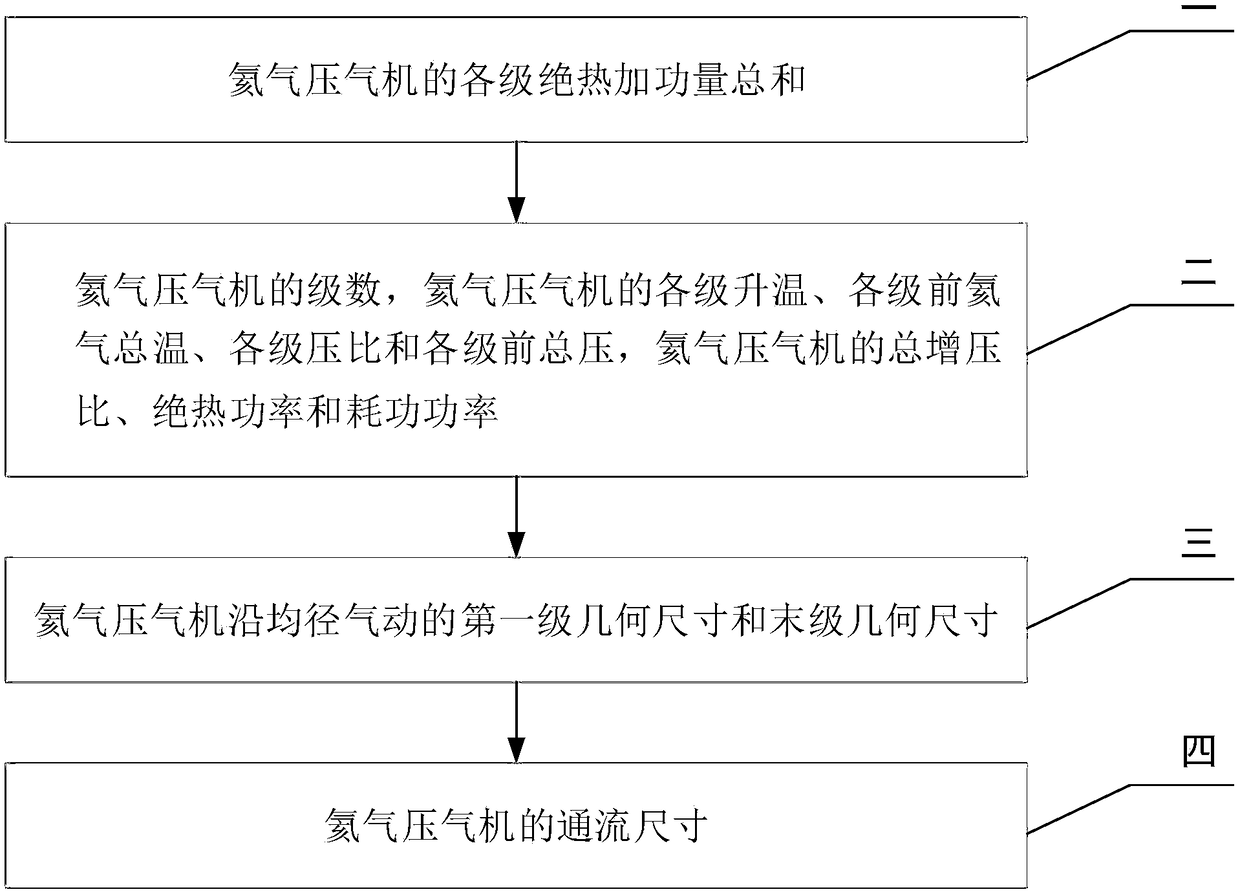

[0013] Specific implementation mode one: as figure 1 As shown, the one-dimensional aerodynamic design method of a helium gas compressor described in this embodiment includes the following steps:

[0014] Step 1. Utilize the flow pressure ratio of the helium compressor Calculate the sum of all levels of adiabatic work of the helium compressor and distribute it reasonably;

[0015] Step 2: Determine the number of stages of the helium compressor, calculate the temperature rise of each level of the helium compressor, the total temperature of the helium before each level, the pressure ratio of each level and the total pressure before each level, and calculate the total increase of the helium compressor Pressure ratio, adiabatic efficiency and power consumption;

[0016] Step 3: Calculate the first-stage geometric dimensions and the last-stage geometric dimensions of the helium gas compressor along the mean diameter;

[0017] Step 4: Obtain the flow size of the helium compressor...

specific Embodiment approach 2

[0018] Specific implementation mode two: the difference between this implementation mode and specific implementation mode one is: the specific process of the step one is:

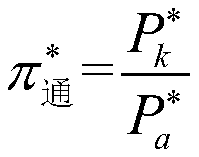

[0019] The pressure of the airflow when the airflow passes through the beginning of the inlet section is P a * , the airflow pressure when the airflow passes through the end of the outlet section is P k * , according to P a * and P k * Calculating the flow-to-flow pressure ratio of a helium compressor

[0020]

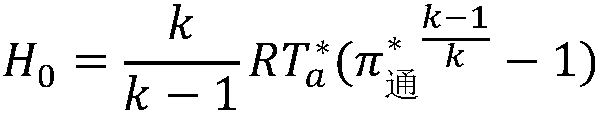

[0021] use Calculation of the adiabatic work H of the helium compressor 0 :

[0022]

[0023] Among them, H 0 is the adiabatic work of the helium compressor, k is the adiabatic index, is the total temperature of the intake air, and R is the gas constant;

[0024] Then the sum of the adiabatic work of all stages of the helium compressor ∑h 0 for:

[0025]

[0026] Among them, η i is the level average efficiency, is the adiabatic efficiency of the helium compressor.

specific Embodiment approach 3

[0027] Specific implementation mode three: the difference between this implementation mode and specific implementation mode two is: the specific process of said step two is:

[0028] Determine the number of stages of the helium compressor, and then calculate the pneumatic parameters of each stage:

[0029] Helium Compressor's i-Stage Heating for:

[0030]

[0031] Where: h s,i is the i-level adiabatic processing capacity, η s,i is the adiabatic efficiency of the i-th stage, and i is the number of stages;

[0032] The total temperature of helium before the i-th stage of the helium compressor is, where the first level is given according to the design requirements:

[0033]

[0034] The i-th stage pressure ratio of the helium gas compressor for:

[0035]

[0036] The total pressure before the i-th stage of the helium gas compressor is , where the first level is given according to the design requirements:

[0037]

[0038] In the formula: Indicates the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com