Split portable multipurpose firewood stove

A portable, wood-burning stove technology, applied in the field of stoves, can solve the problems of poor fuel combustion controllability, low frequency of use of wood-burning stoves, heavy weight of wood-burning stoves, etc., and achieves the effects of improving fuel utilization, reducing the frequency of adding fuel, and saving space.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

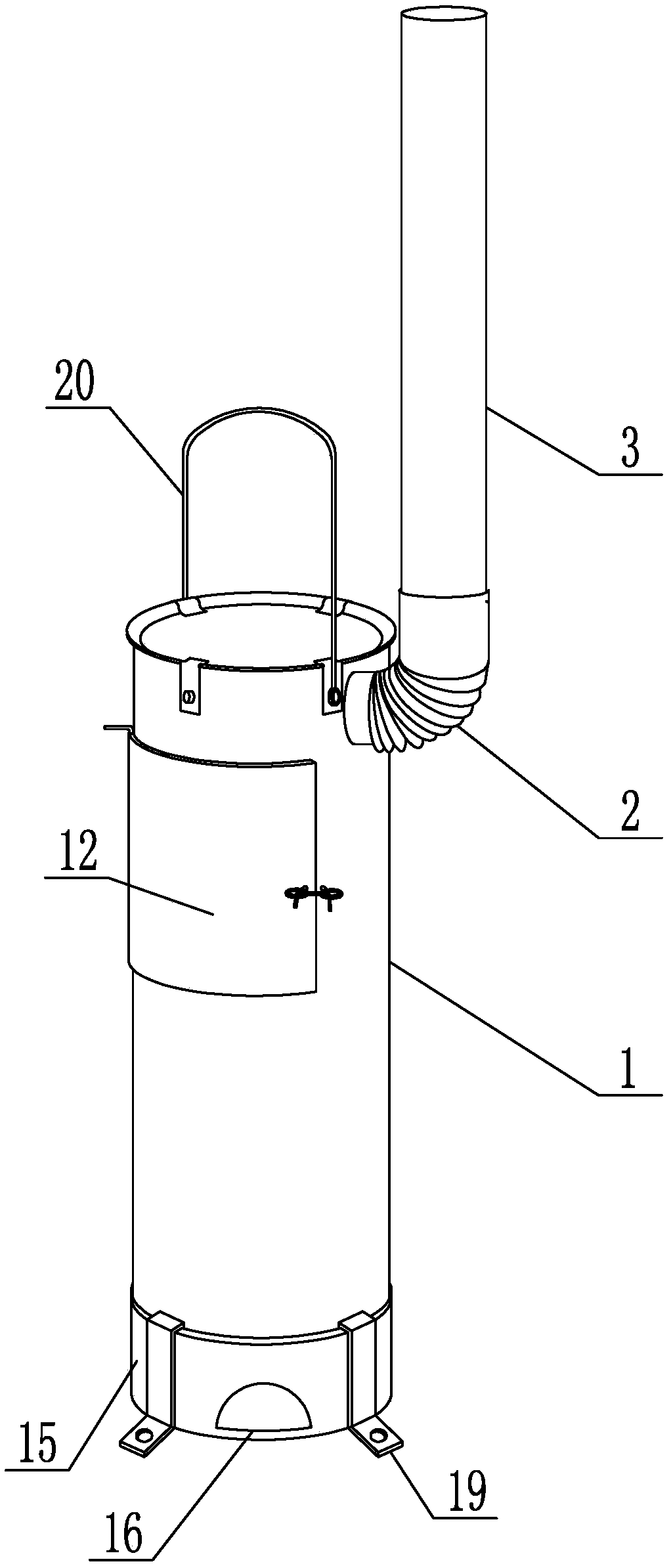

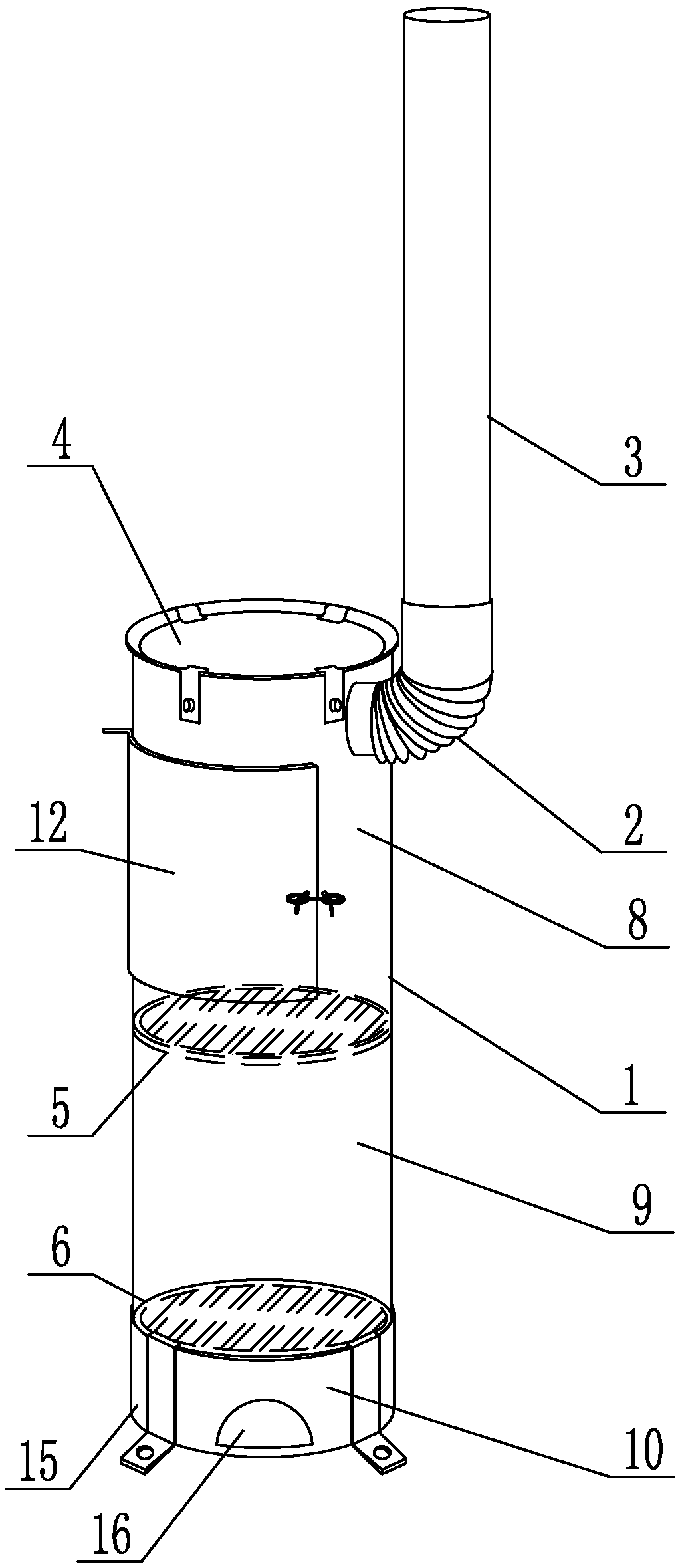

[0036] Specific implementation mode one: as Figure 1 to Figure 11 As shown, this embodiment includes a detachable furnace body 1, a steering cylinder 2, a smoke exhaust pipe 3, an upper furnace pan 4, an upper furnace grate 5, a lower furnace grate 6 and a lower furnace pan 7. The detachable furnace body 1 includes two Two composition sheets 1-1 are enclosed to form a cylindrical furnace body between the two composition sheets 1-1, and the upper furnace pan 4 and the lower furnace pan 7 are respectively arranged on the top and bottom ends of the detachable furnace body 1, and the upper furnace grate 5 and the lower grate 6 are horizontally arranged inside the detachable furnace body 1, and the inside of the detachable furnace body 1 is isolated from the upper furnace grate 5 and the lower furnace grate 6 to form an upper furnace 8, a lower furnace 9 and a The ash chamber 10, the outer wall of the detachable furnace body 1 is provided with a steering cylinder 2, the smoke exha...

specific Embodiment approach 2

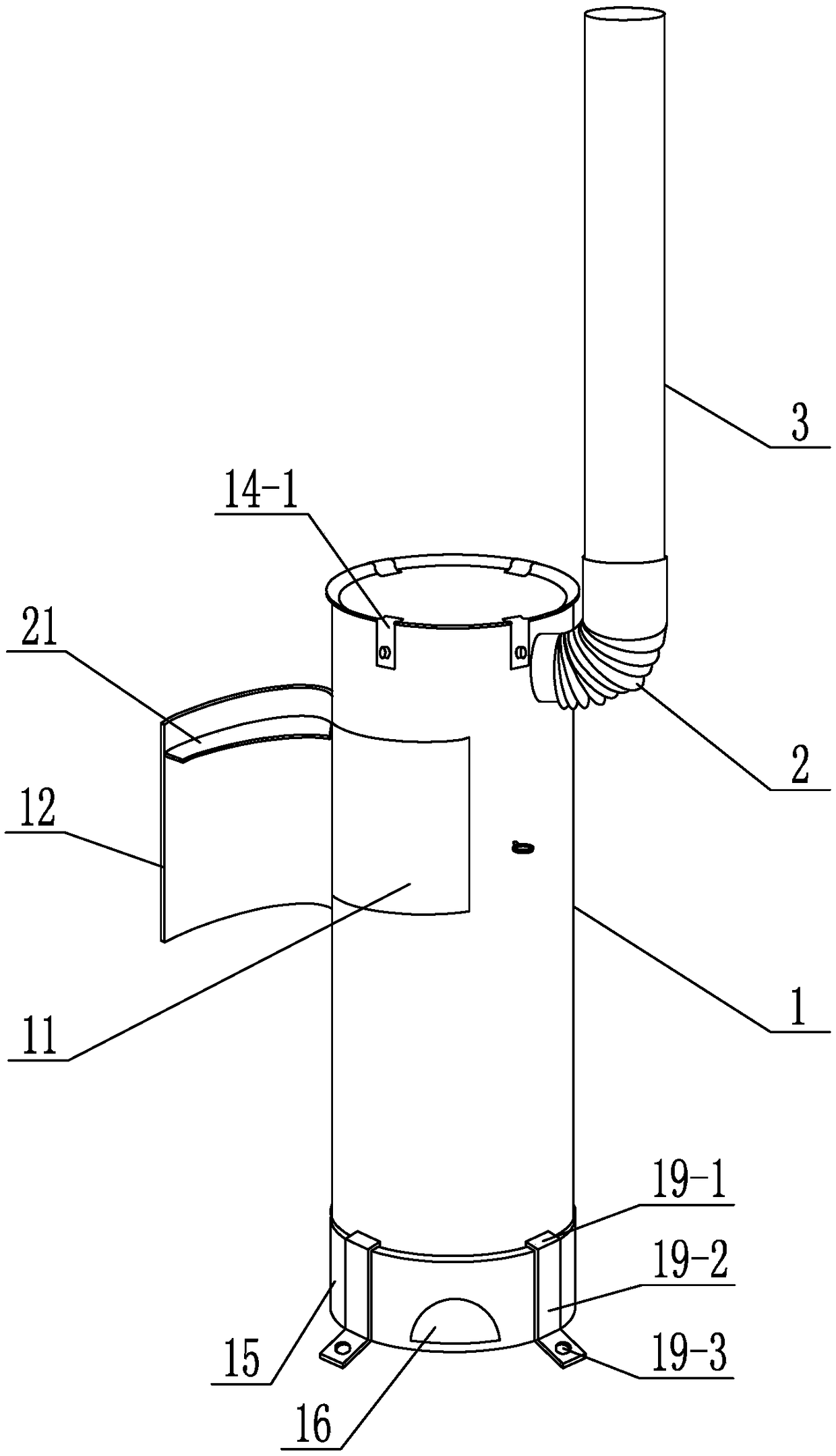

[0040] Specific implementation mode two: as figure 2 As shown, the outer wall of the detachable furnace body 1 is processed with an opening 11 communicating with the upper furnace 8, the opening 11 is hinged with a furnace door 12, and the furnace door 12 is detachably connected to the detachable furnace body 1, and the opening 11 A sleeve is processed on one side, and one side of the furnace door 12 is detachably connected to the sleeve at the opening 11 through the insert rod, which facilitates the opening and closing of the furnace door 12 in the detachable furnace body 1, and also facilitates the furnace door 12 from the detachable furnace body. Body of furnace 1 is disassembled and installed, strengthens the characteristics of the present invention's overall disassembly and installation. The inner wall of the furnace door 12 is provided with a retaining strip 21, and the retaining strip 21 blocks the gap formed between the furnace door 12 and the upper end of the opening...

specific Embodiment approach 3

[0042] Specific implementation mode three: as image 3 and Figure 8 As shown, the upper furnace grate 5 and the lower furnace grate 6 have the same structure, and both are existing products. The upper furnace grate 5 is detachably connected to the inside of the detachable furnace body 1, and the lower furnace grate 6 is detachably connected to the detachable body of furnace 1. Inside the furnace body 1, the inside of the detachable furnace body 1 is isolated from top to bottom by the upper furnace grate 5 and the lower furnace grate 6 to form the upper furnace 8, the lower furnace 9 and the ash falling chamber 10, the upper furnace 8 and the lower furnace 9 At two different heights up and down, the upper hearth 8 is used for cooking, so that the flame of the upper hearth 8 is effectively close to the upper pan 4, and the flame temperature of cooking is enhanced. When heating, the upper grate 5 is disassembled, so that the upper hearth 8 and the lower The furnace 9 is combine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com