Decorative part with lamps

A technology of decorative parts and lights, which is applied to the parts of lighting devices, lampshades, lighting devices, etc., can solve the problems of unclear contours of illuminants, gap errors, and time-consuming production, and achieve better luminous display effects and smaller sizes. The effect of high precision and stable integrated structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The technical solution of the present invention will be further described and illustrated through specific embodiments and accompanying drawings below. Unless otherwise specified, the raw materials used in the examples of the present invention are commonly used raw materials in the art, and the methods used in the examples are conventional methods in the art.

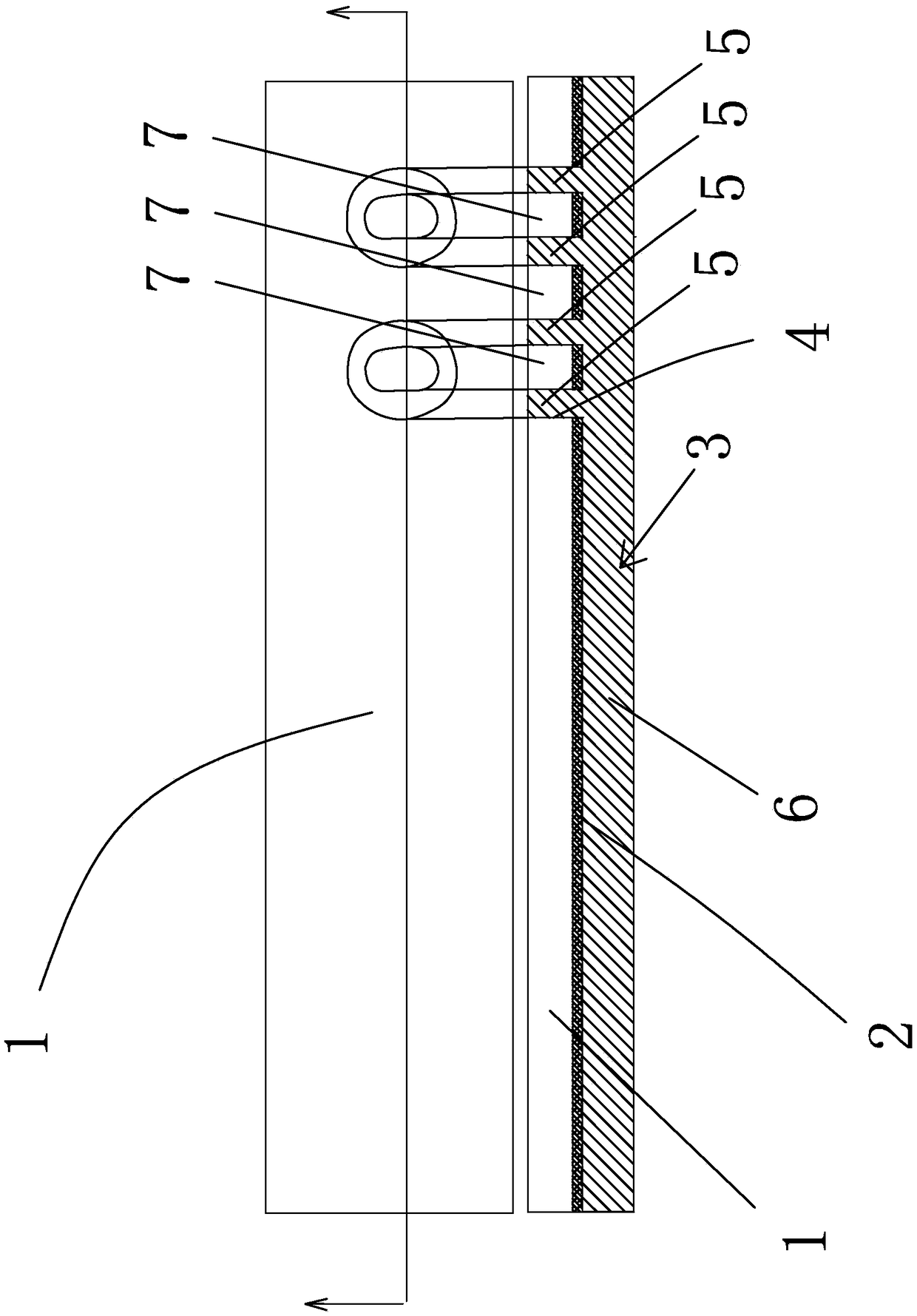

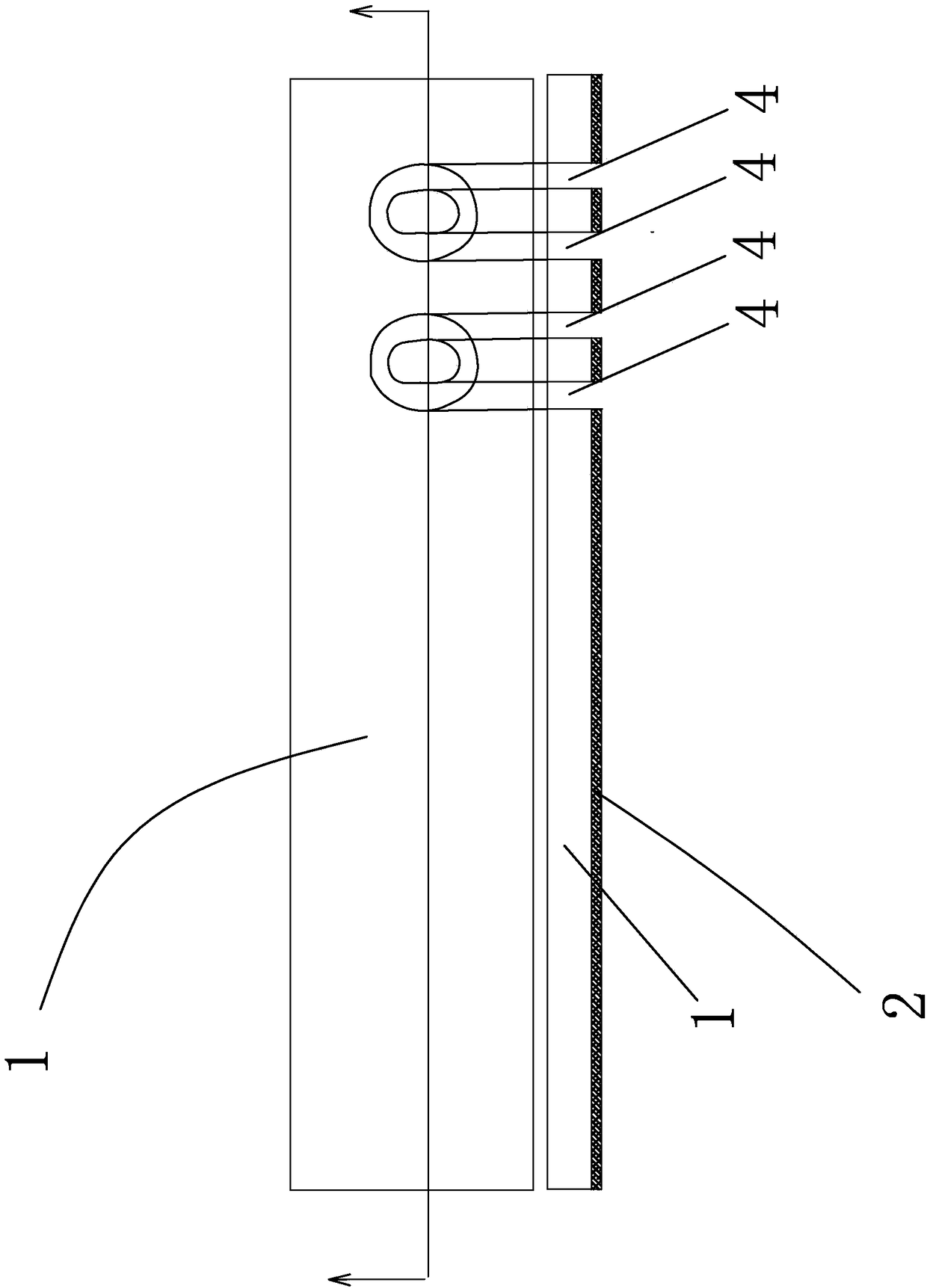

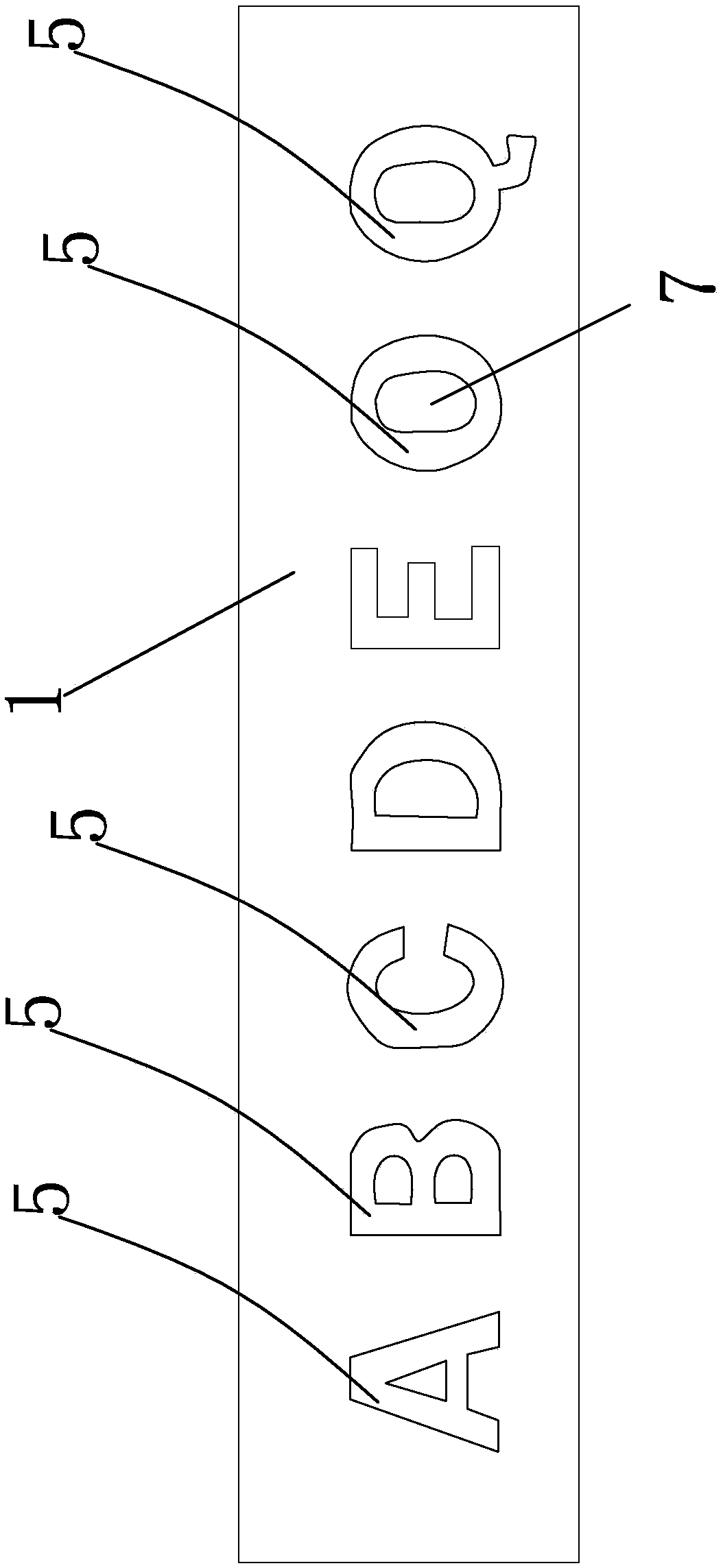

[0017] In the figure, sheet body 1; glue body 2; light-transmitting plastic body 3; through hole 4; font light-transmitting part 5; overall light-transmitting part 6;

[0018] Such as Figure 4 as well as image 3 As shown, the decorative part with lights can be formed with ABCDEOQ expected graphic fonts etc. on its upper surface. Here, this patent is explained with the expected graphic font of OQ. The light-transmitting plastic body 3, the light-transmitting rate of the light-transmitting plastic body 3 is ≥ 60%, and the haze is ≥ 80%, which is conducive to the light transmission of the entire decorative part,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

| haze | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com