Method for downhole solving water blocking of mining-induced L-shaped well

An L-shaped, well water technology, applied in wellbore/well components, drainage, production fluids, etc., can solve problems such as impact, and achieve the effect of ensuring smooth progress, saving costs, and avoiding waste of manpower and material resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

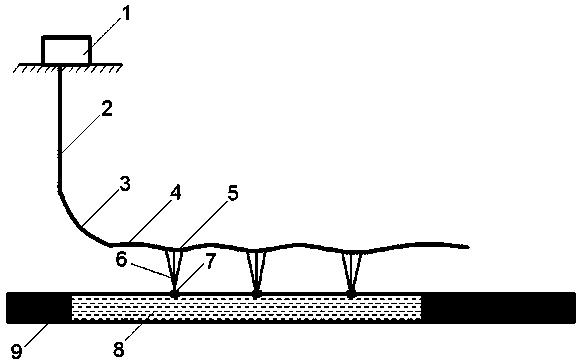

[0020] This embodiment provides an underground method for solving L-shaped well water plugging in mining, including the following steps,

[0021] S1, determine the L-shaped well trajectory depression

[0022] Draw the L-shaped well trajectory according to the logging-while-drilling data, and obtain the specific position of the depression section 5 of the L-shaped well trajectory;

[0023] S2, Optimizing the Design Parameters of Hydrophobic Pores

[0024] According to the specific position of the concave section 5 of the L-shaped well trajectory, the drilling site 7 is set in the downhole roadway 8 below the L-shaped well, and 2-3 drainage holes 6 are constructed in each drilling site 7. According to relevant data, the size of the drainage holes 6 is optimized. Construction azimuth, top angle and construction length;

[0025] S3, construction of drainage holes

[0026] Open a hole from the side wall or roof of the underground roadway 8, drill no less than 5 meters, lower the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com