Textile fabric hanging device

A hanging device and technology of textile fabrics, applied in the field of textile fabrics, can solve the problems of inconvenient hanging and collecting, and achieve the effects of convenient drying and collecting, time-saving and labor-saving operation, and adjustable height

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

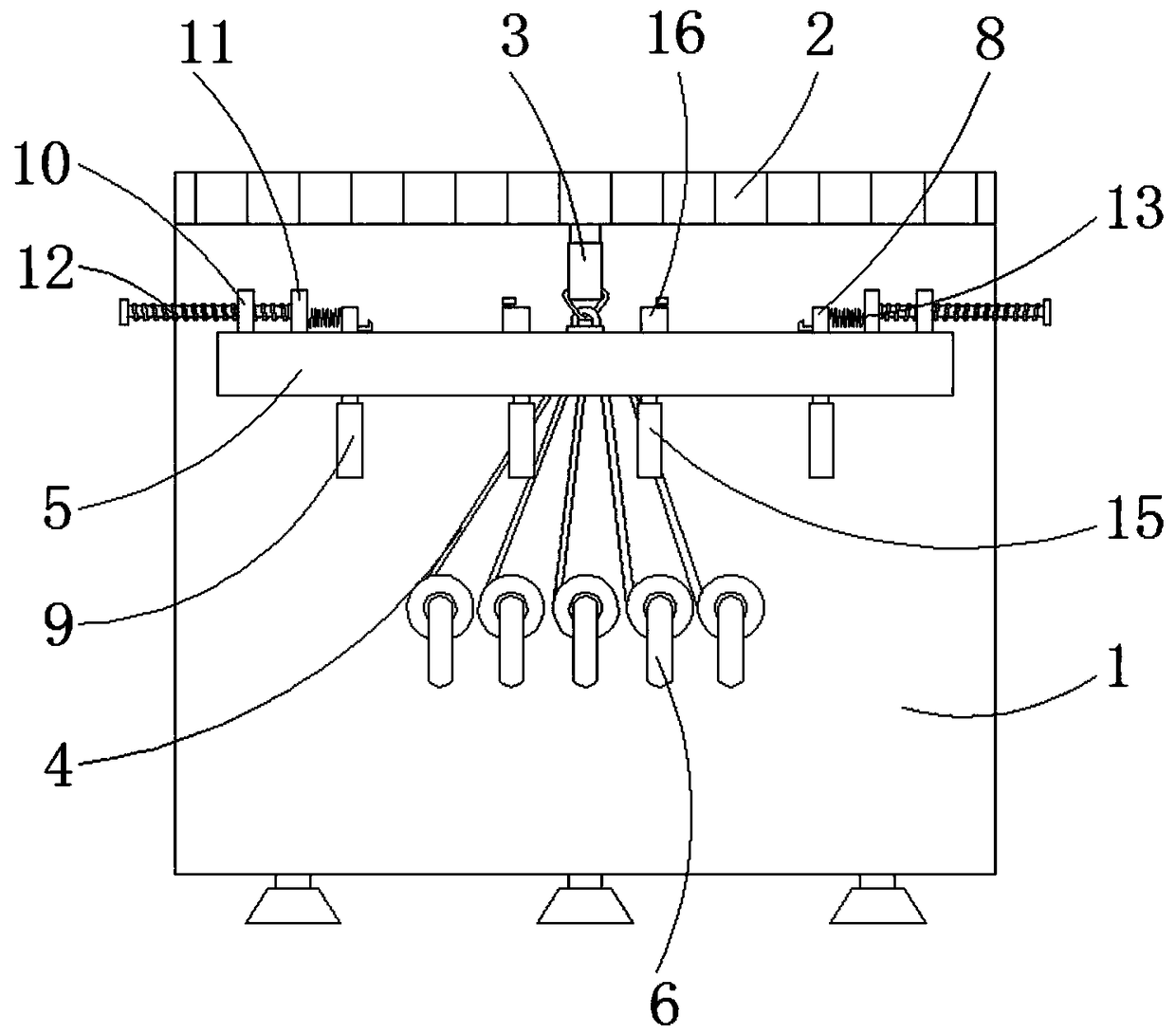

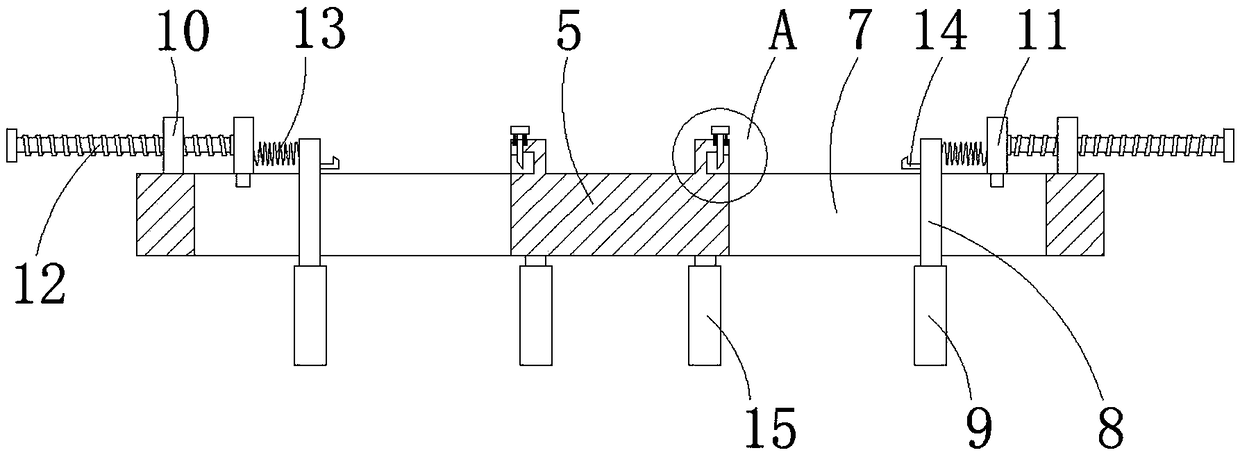

Embodiment 1

[0034] Embodiment 1: When hanging the dyed fabric, shake the hand crank 6 to release the cable 4. Due to gravity, the suspender 5 descends. The bar 5 remains still, and then the slide bar 8 is pushed, the first spring 13 is stretched, and a slope is provided on one side of the stop block 14, which can push the stop bar 18 to slide upwards, and the second spring 19 is stretched, and the position is limited. The block 14 is inserted into the inside of the connecting groove 17, and then the second spring 19 is due to elastic rebound, and the stop bar 18 resets to form a stop to the stop block 14, preventing the slide bar 8 from rebounding, and the slide bar 8 is fixed. Then, use Move spring clip 9 fixed one corner of cloth, fix another corner of cloth with fixed spring clip 15, then upwards carry stop bar 18, stop bar 18 loses the limit to stop block 14, first spring 13 is due to elastic rebound, Drive the slide bar 8 to reset, the distance between the movable spring clip 9 and t...

Embodiment 2

[0035] Embodiment two: when hanging the cloth of different specifications, turn the screw rod 12, the screw rod 12 rotates and moves relative to the fixed plate 10, and drives the sliding plate 11 to slide along the sliding groove 7. After the position of the sliding plate 11 is changed, the movable spring clip 9 and Determine the expansion distance of the spring clip 15.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com