Three-axis visual auto-screwdriving machine

An automatic locking screw machine, visual technology, applied in metal processing equipment, metal processing, manufacturing tools and other directions, can solve problems affecting product processing quality, destroying screw hole positions, inaccurate positioning, etc., to increase the quality of locking screws, guaranteeing Precise positioning and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

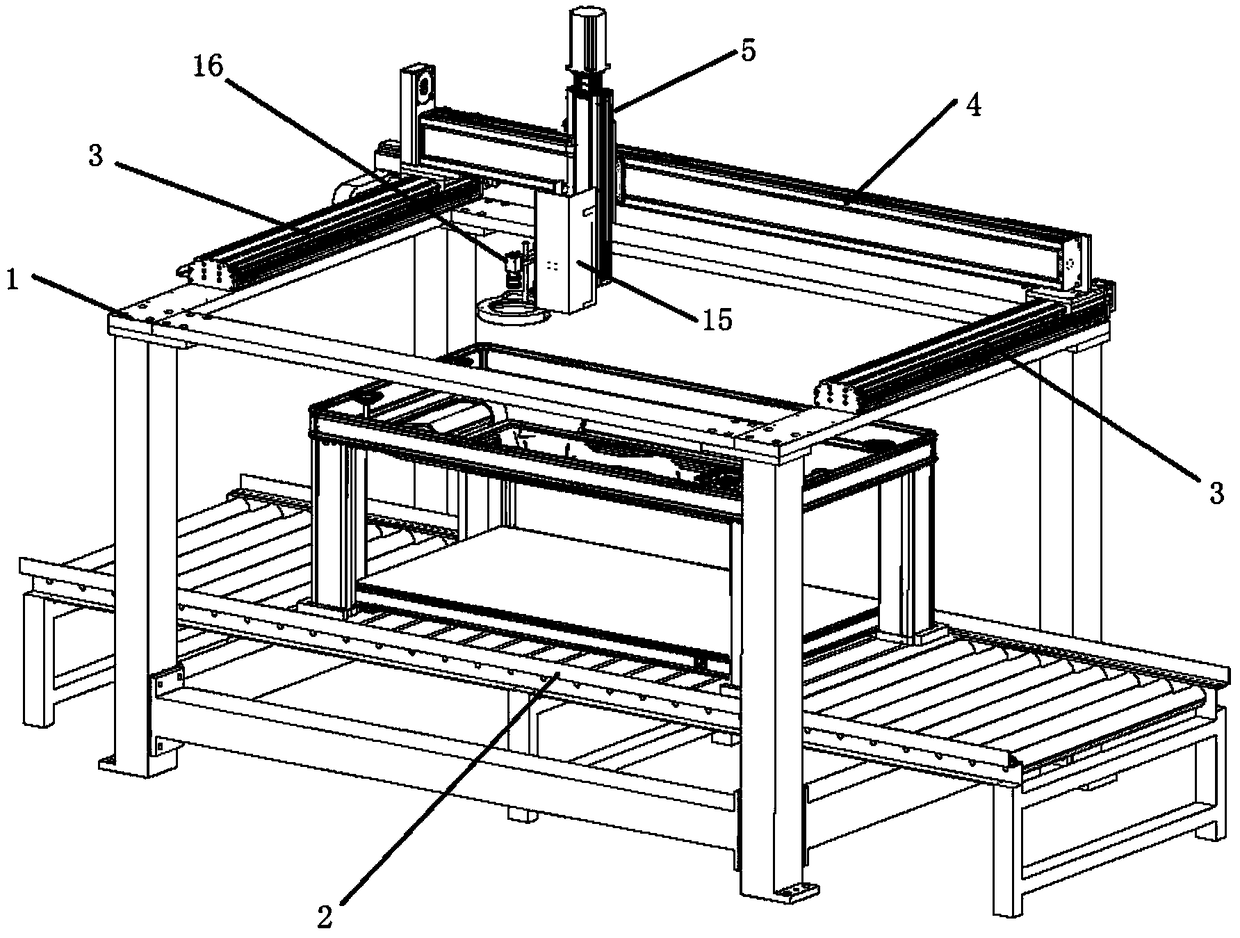

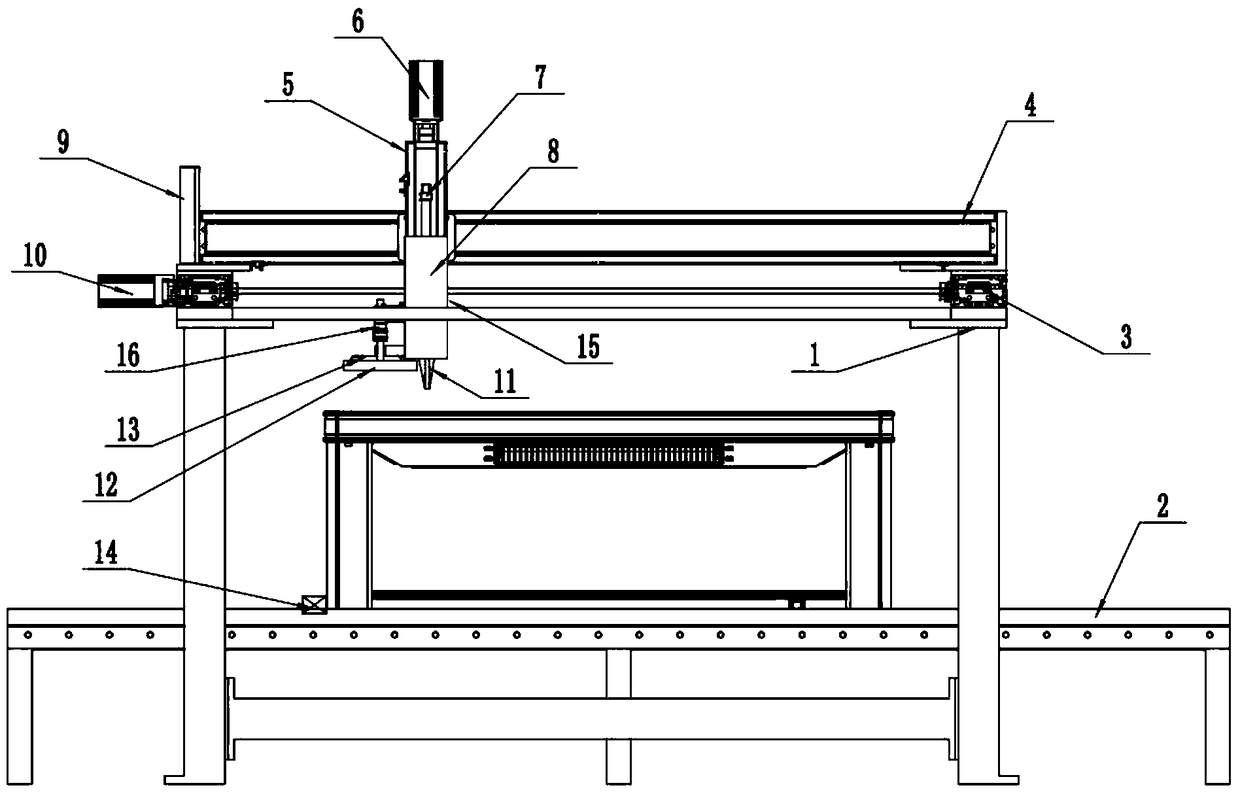

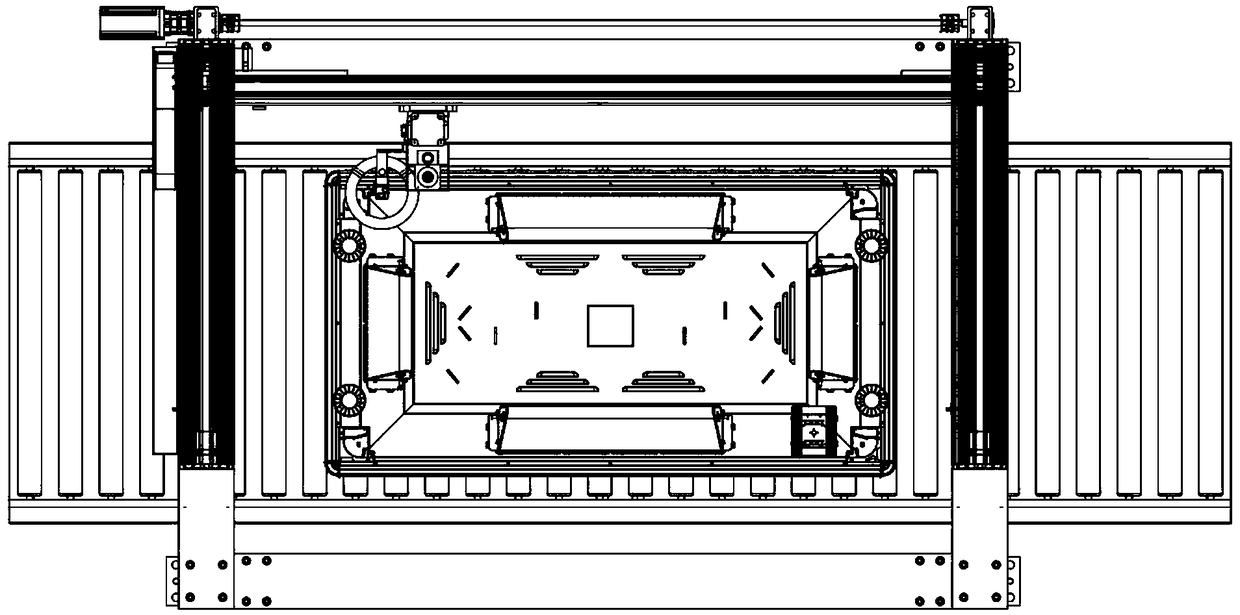

[0024] refer to Figure 1~3 , in an embodiment of the present invention, a three-axis visual automatic screw locking machine includes a load-bearing frame 1, the weighing frame 1 belongs to a steel structure, which can prevent the module from shaking during operation, and the middle of the lower end of the load-bearing frame 1 is provided with The positioning roller conveying line 2, the workpiece to be processed is placed on the positioning roller conveying line 2, the Y-axis module 3 is installed on the left and right sides of the upper end of the load-bearing frame 1, and the Y-axis module 3 moves stably and at a fast speed. An X-axis module 4 is installed between the middle parts of the axis modules 3, and the movement of the Y-axis module 3 is also stable and fast. The X-axis module 4 includes an X-axis servo motor 10 and a speed-changing synchronous wheel 9, X A Z-axis module 5 is installed in the middle of the axis module 4. The Z-axis module 5 includes a Z-axis motor 6...

Embodiment 2

[0026] In another embodiment of the present invention, the difference between this embodiment and the above-mentioned embodiment is that a positioning blocking cylinder 14 is installed on the upper end of the positioning roller conveying line 2, and the positioning blocking cylinder 14 can effectively move the to-be-processed The workpiece is limited on the positioning roller conveying line 2, thereby effectively avoiding shaking when the workpiece is tightened.

[0027] In the present invention, when in use, the workpiece product is conveyed through the positioning roller conveying line, and then the visual device is used to guide the cooperation between the X-axis module, the Y-axis module and the Z-axis module, so that the nail feeding mechanism 15 drives the cross The batch head 11 is rotated to tighten the screw in the product, ensuring machining accuracy, simple operation and strong practicability.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com