SIMULINK based parameter influence degree analysis method of load simulator

A load simulator and analysis method technology, applied to controllers with specific characteristics, electric controllers, etc., can solve problems such as less reverse thinking, dependence on linear transfer functions, weak attention to system performance, etc., to improve parameters The effect of influence analysis method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

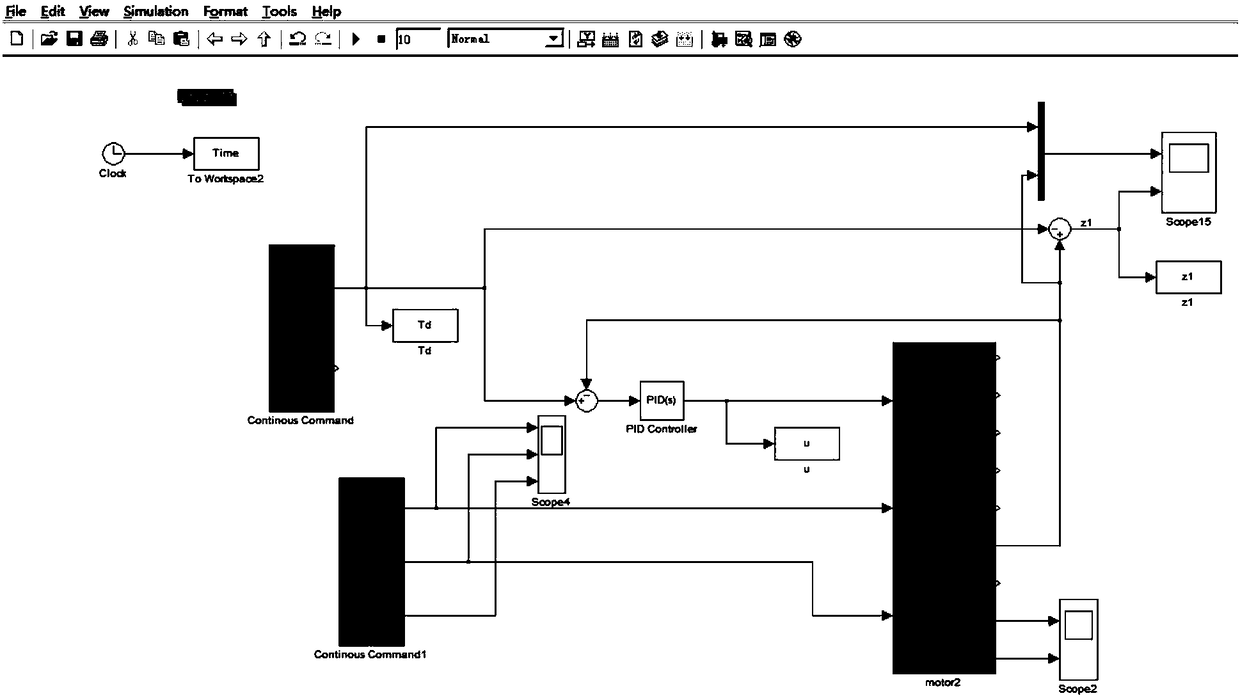

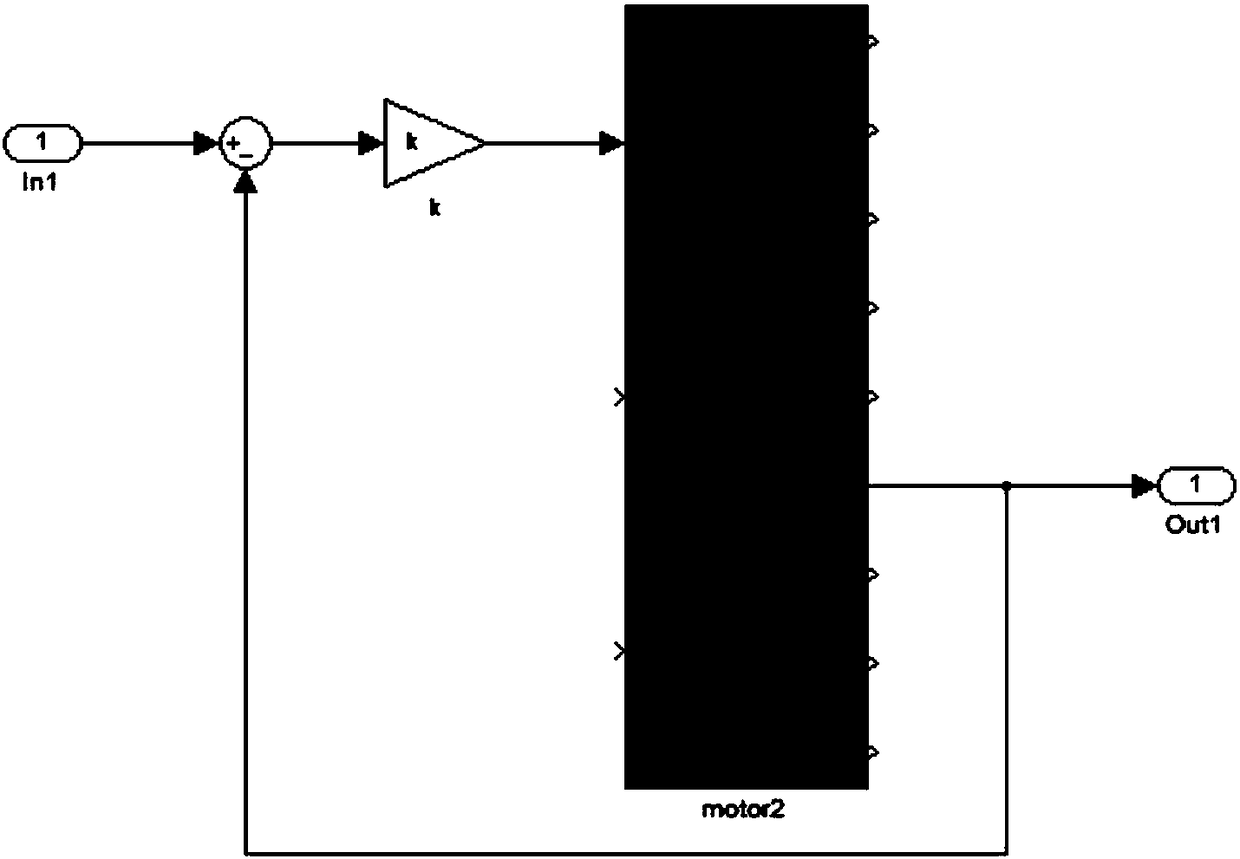

Method used

Image

Examples

Embodiment

[0075] The parameters of the dual vane hydraulic motor force control load simulator are:

[0076] A=2×10 -4 m 3 / rad, B=800N m s / rad, β e =2×10 8 Pa, C t =9×10 -12 m 5 / (N·s), P s =21×10 6 Pa, P r = 0 Pa, V 01 =V 02 =1.7×10 -4 m 3 , J=0.32kg·m 2 .

[0077] Comparing the simulation results: during the simulation, the parameter P in the PID controller is mainly adjusted, and the parameters of the PID controller designed by the present invention are selected as: P=0.05, I=0, D=0.

[0078] The time-varying external disturbance of the system is selected as d=200sint, and the trajectory is The high-frequency torque command that the system expects to track is a curve The low frequency torque command is

[0079] Figure 5 It is the high frequency torque command curve (5HZ) of the system. Figure 6 is the curve of the system tracking error changing with time. It can be seen that the tracking error is bounded and convergent, and this bound is very small compared...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com