Fluid pump and method for assembling fluid pump

The technology of a fluid pump and main body is applied to the components of the pumping device for elastic fluid, the pump device, the pump, etc., to achieve the effect of reducing the production cost and reducing the production effort.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

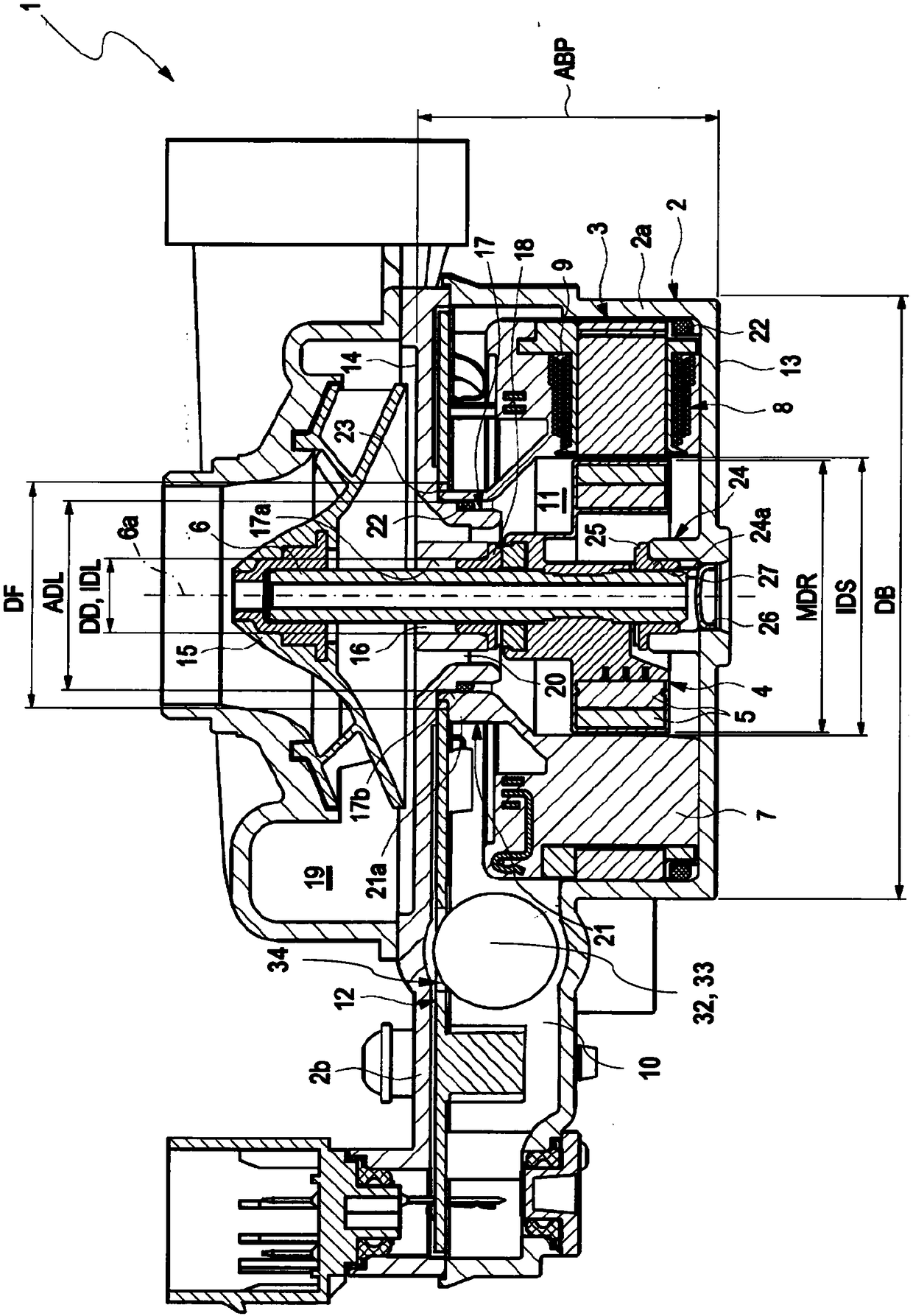

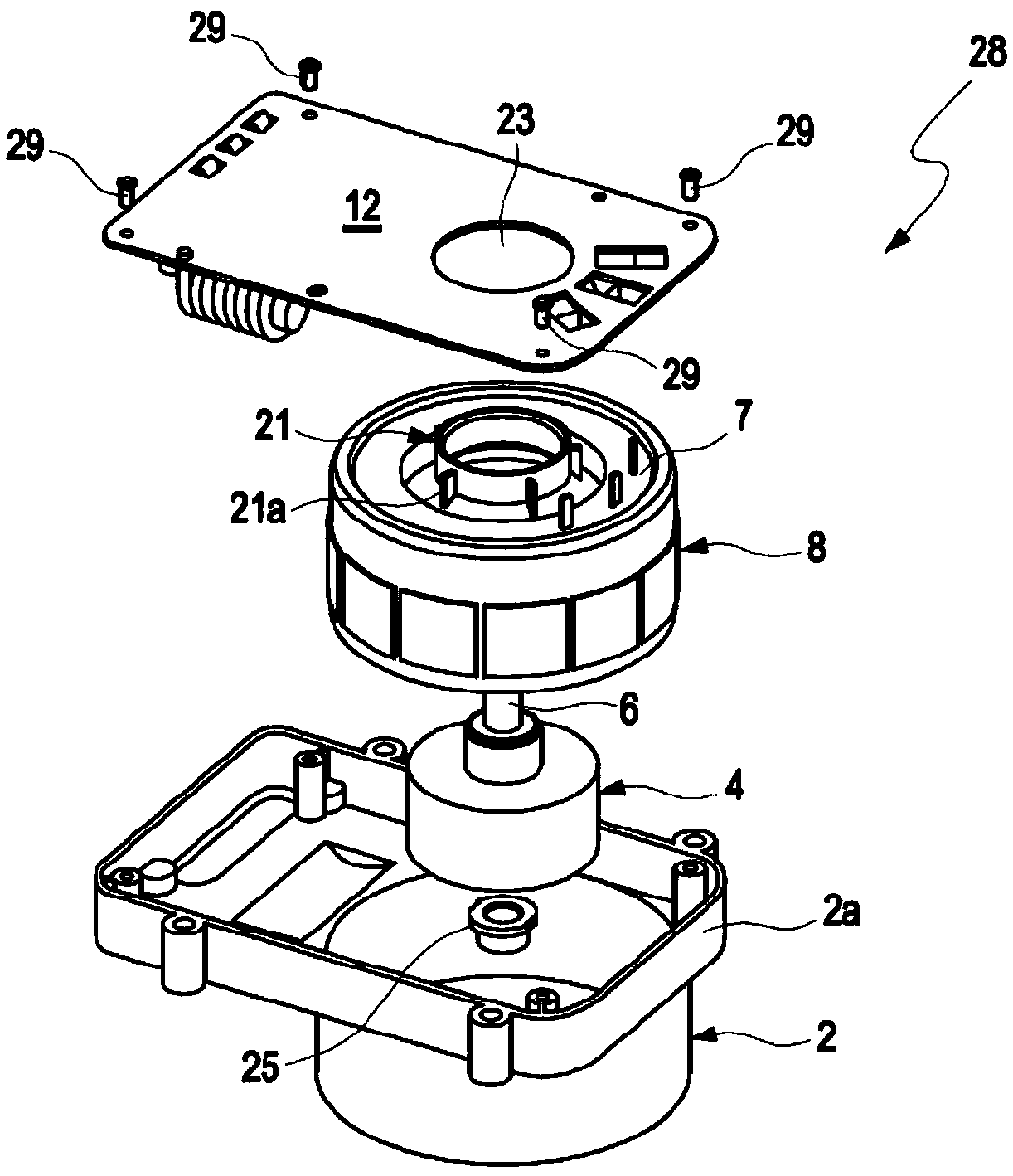

[0028] figure 1 A sectional view of an electric fluid pump 1 according to the invention is shown. The fluid pump 1 has a pump housing 2 and an electric motor 3 arranged in the pump housing 2 . The pump housing 2 is formed in this case by a housing bottom 2 a and a housing cover 2 b. A rotor 4 with permanent magnets 5 is fixed for common rotation to a rotor shaft 6 and is mounted in a stator body 7 with an embedded stator 8 so as to be rotatable about an axis of rotation 6a. The stator 8 has a plurality of coils 9 and other electronic components embedded in the stator body and surrounded by the material of the stator body 7 (eg plastic). In this way, the coils 9 and other electronic components of the stator 8 can be protected from the fluid to be pumped. The stator body 8 is surrounded by a part-cylindrical housing bottom 2a, so that the heat generated in the stator body 7 can be dissipated to the outside. For this purpose, the housing bottom 2a can be made of aluminum, for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com