A drag-reducing micro-nano composite structure for hull and its preparation method

A composite structure, micro-nano technology, applied in the field of preparation of ship hull micro-nano structure, can solve the problem of neglecting the wettability of the hull surface, and achieve the effects of easy operation, reduced forward resistance and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

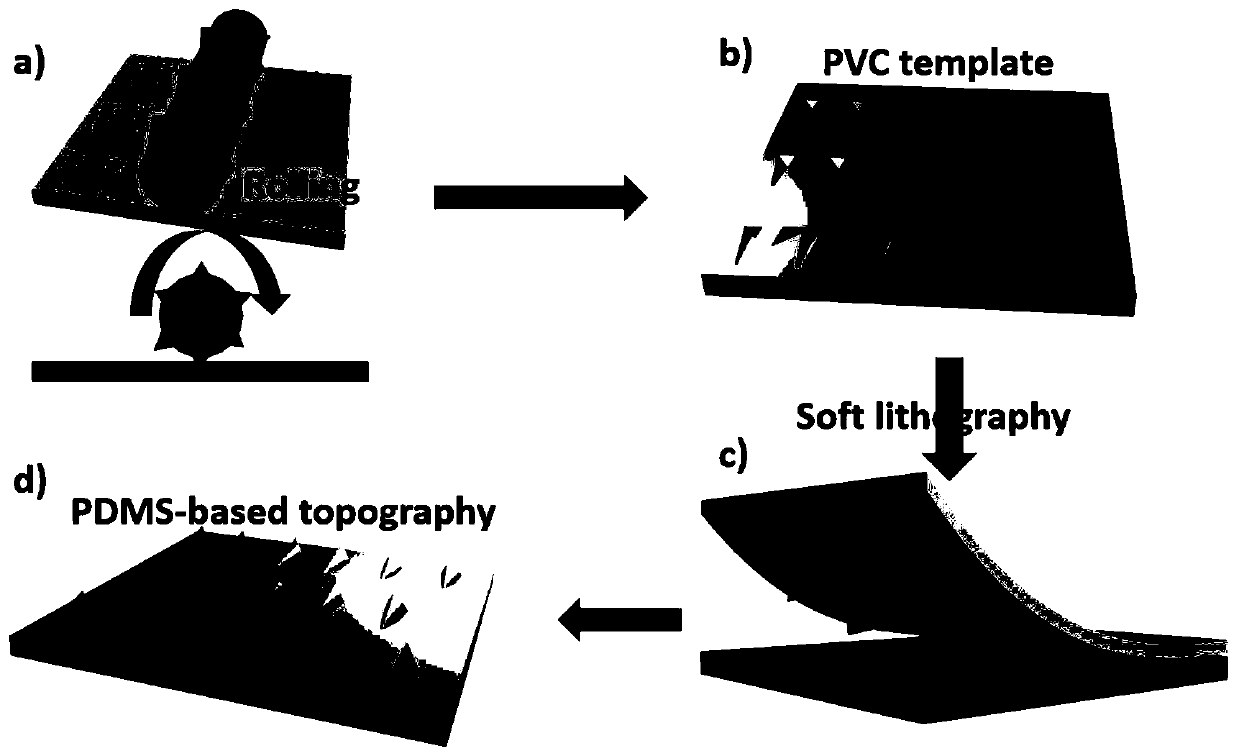

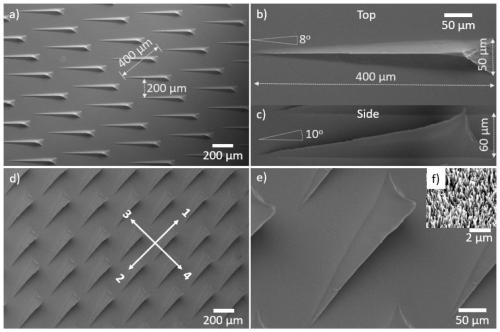

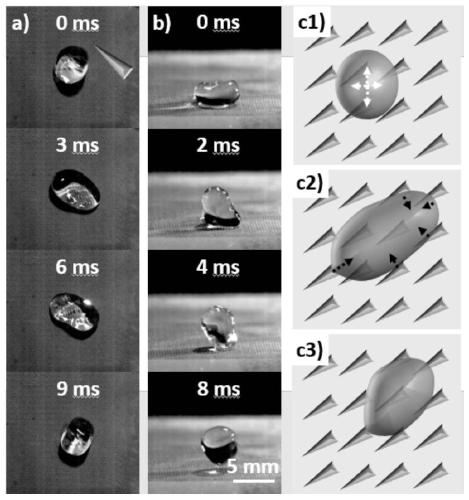

[0034] For the preparation method, see figure 1 , this embodiment is a method for preparing an anisotropic superhydrophobic structure, which can effectively reduce the running resistance of the hull, and specifically includes the following steps:

[0035] (1) Put the tip of the surgical blade outward, and stick solder on the other end, and perform welding operation under a microscope by micromachining, so that the tip of the scalpel is closely arranged on the surface of the metal roller to form an array with controllable spacing. A metal rod with a scalpel blade is rolled on the surface of a high-density polyethylene (PE) plate, leaving an array of scalpel blade anti-structures.

[0036] (2) PDMS (polymethylsiloxane) and curing agent are mixed at a volume ratio of 10:1, vacuumed to remove internal air bubbles, and then poured on the surface of the PE template. After a curing time of 3 hours, the template was uncovered to obtain a flexible anisotropic surgical blade structure ...

Embodiment 2

[0046] This embodiment is a method for preparing an anisotropic superhydrophobic structure, which specifically includes the following steps:

[0047] (1) Fix the surgical blade (commercially available) on the three-dimensional platform at an angle of 45 degrees, and control the spacing of each microstructure through the x and y directions of the three-dimensional platform, which can be regulated at 50-500 microns; through z (vertical) Adjust the depth in the direction to adjust the height of the structure, periodically focus on the surface of the PE board, and form a blade anti-structure array on the surface of the PE board.

[0048] (2) PDMS (polymethylsiloxane) and curing agent are mixed at a ratio of 15:1, the internal air bubbles are removed by vacuum, and then poured on the surface of the PE template. After a curing time of 3 hours, the template was uncovered to obtain a flexible anisotropic surgical blade structure on the PDMS substrate.

[0049] (3) The preparation of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com