Mold for reinforcement framework stretching

A steel skeleton and tensioning technology, applied in the direction of manufacturing tools, ceramic molding machines, etc., can solve the problems of slow transportation, affecting process efficiency, cumbersome and other problems, and achieve the effect of good support

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

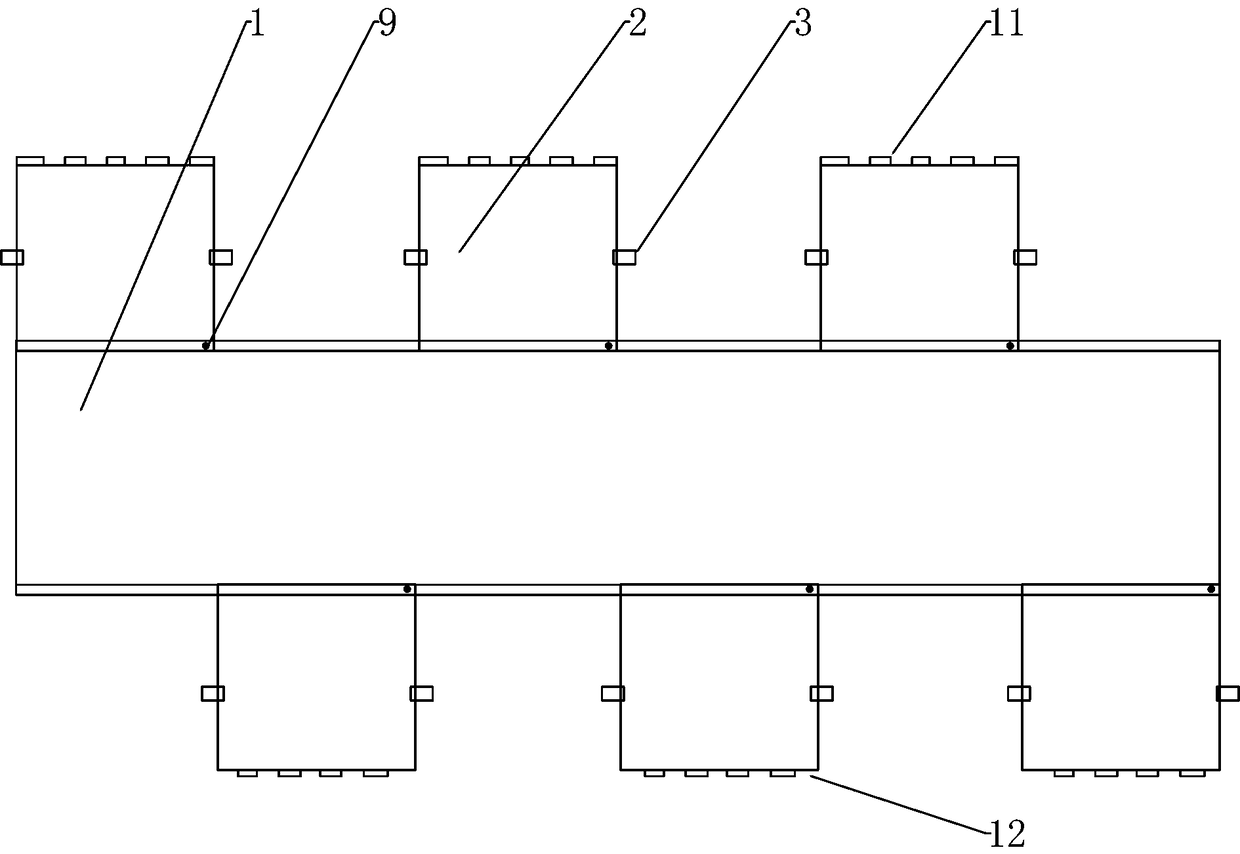

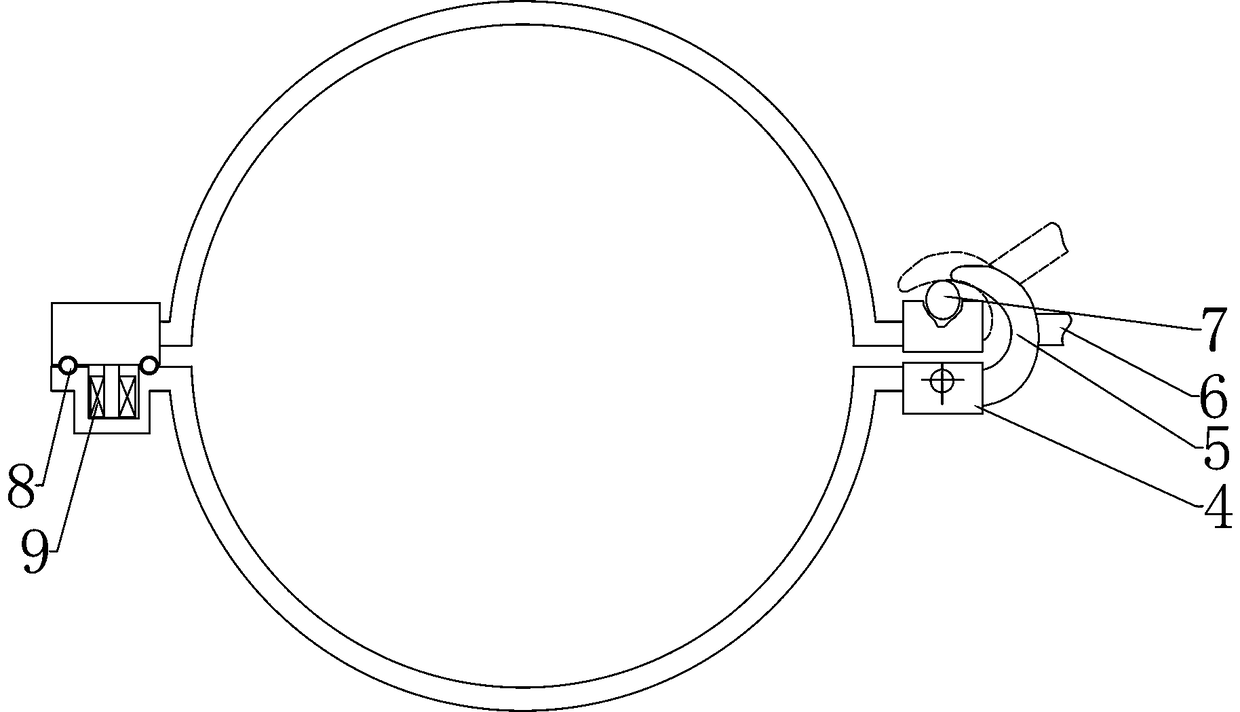

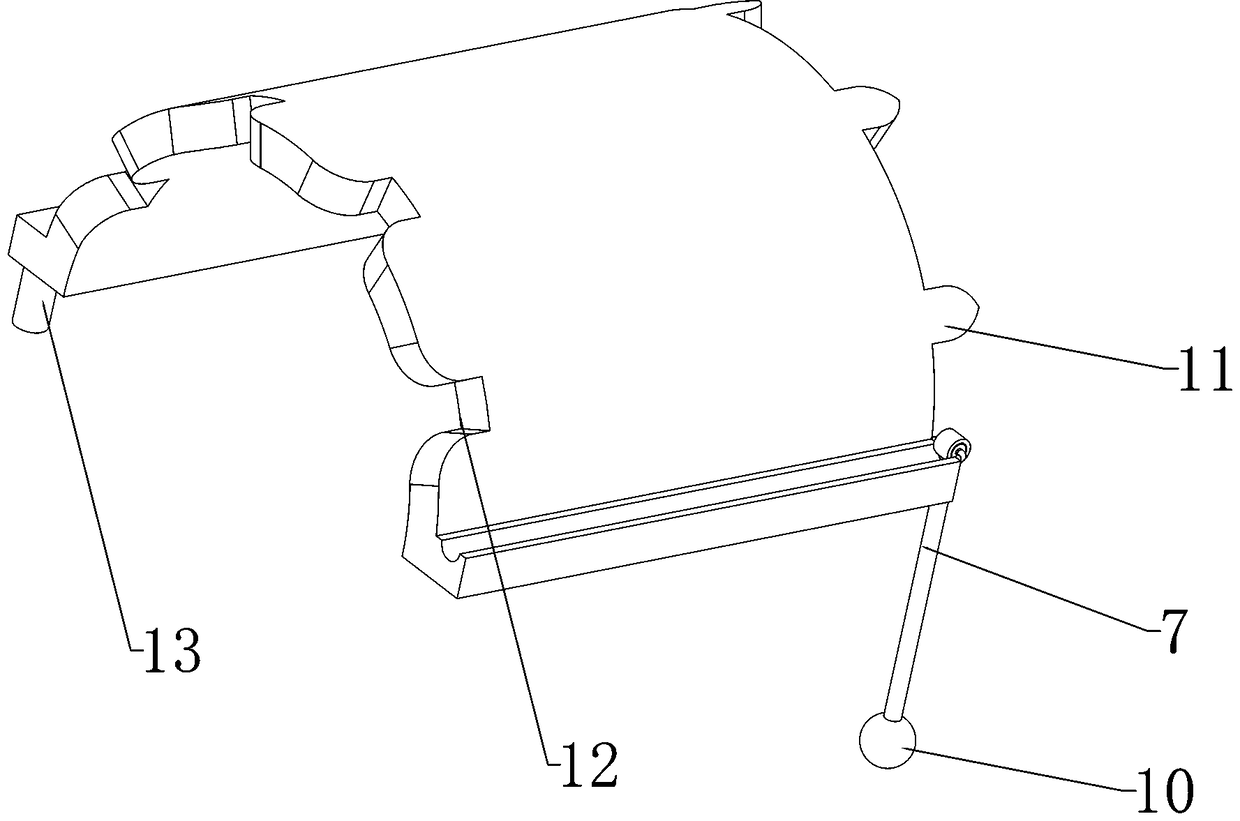

[0020] Such as Figure 1-4 As shown, a mold for stretching a steel bar skeleton includes a lower mold 1 and an upper mold. The lower mold 1 is an integral semicircular arc shell, and the lower mold 1 is fixedly installed on the ground. The upper mold is formed by splicing a plurality of mold covers 2, and the plurality of mold covers 2 are hinged to the lower mold 1 through bearings 9, and the hinge points are staggered left and right. The two ends of the mold cover at the beginning and the end are closed by the end cover with holes, which is convenient for later tensioning. Since the hinge points are staggered on both sides, the details are as follows: figure 1 As shown, this method can ensure that when the mold cover 2 is rotated from one side of the lower mold to the other side, it will not be restricted by adjacent mold covers, and it will be easy to open. Tapered roller bearings are used at the hinge points, and a ring of steel balls 8 is installed above the correspondi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com