Rotary tiller

A technology for a rotary cultivator and a body is applied in the field of rotary cultivators, and can solve the problems of difficulty in taking into account the matching relationship of transmissions, the inability of rotary cultivators to achieve in-situ rotation reversal, and the complex structure of transmissions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

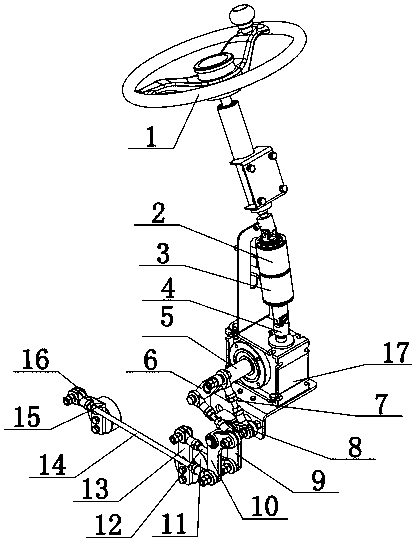

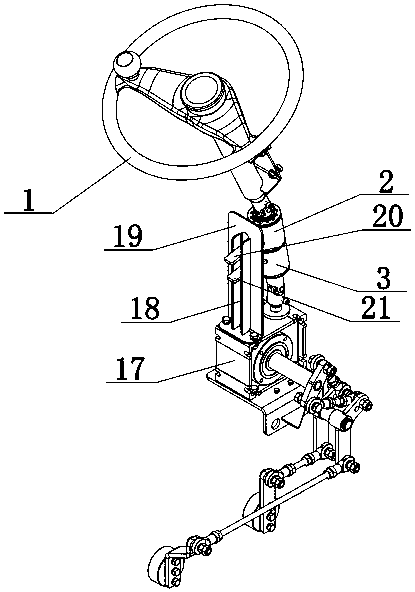

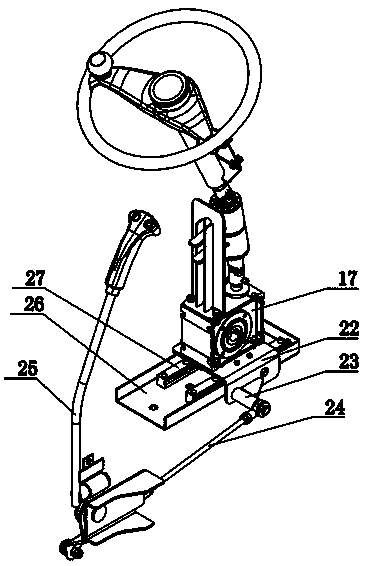

[0026] The present invention will be further described below in conjunction with the accompanying drawings of the description.

[0027] As shown in the figure, the rotary cultivator includes a body in which a variable speed and reversing transmission mechanism, a 360-degree rotating crawler drive mechanism, and a reduction box for implements are arranged in the body. An engine 62, a pump body assembly 61, and a pump body are also arranged in the body. The assembly 61 includes a first variable pump 29, a second variable pump 30, and a third variable pump 61a. The third variable pump 61a is connected to the implement motor 47 for control. The first variable pump 29 and the second variable pump 30 are respectively connected to the left and right crawler Drive motor control connection.

[0028]The shifting and reversing transmission mechanism includes a reversing transmission mechanism and a shifting lock handle transmission mechanism; the reversing transmission mechanism includes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com