A Container Port Production Scheduling System

A production scheduling and container technology, applied in the field of electronic information, can solve problems such as difficulties in port production scheduling, and achieve the effect of improving service quality, high efficiency, and low risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A container port production dispatching system, comprising: a ship berthing planning module, a stowage monitoring module, a storage yard monitoring module and a crossing monitoring module. The main feature of the ship berthing planning module is to process ship berthing applications, formulate berthing and berthing plans and compile day and night production plans; Specific requirements such as moderate seaworthiness must also meet the requirements of the wharf production organization; the main function of the yard monitoring module is to allocate yard operation machinery reasonably and effectively, and ensure the improvement of the external service level of the wharf and other production of the wharf. Under the premise that the operation is not affected, all links on the site are coordinated, and various operations can be completed smoothly, orderly, quickly, safely and effectively; the main function of the crossing monitoring module is to ensure the stacking quality of ...

Embodiment 2

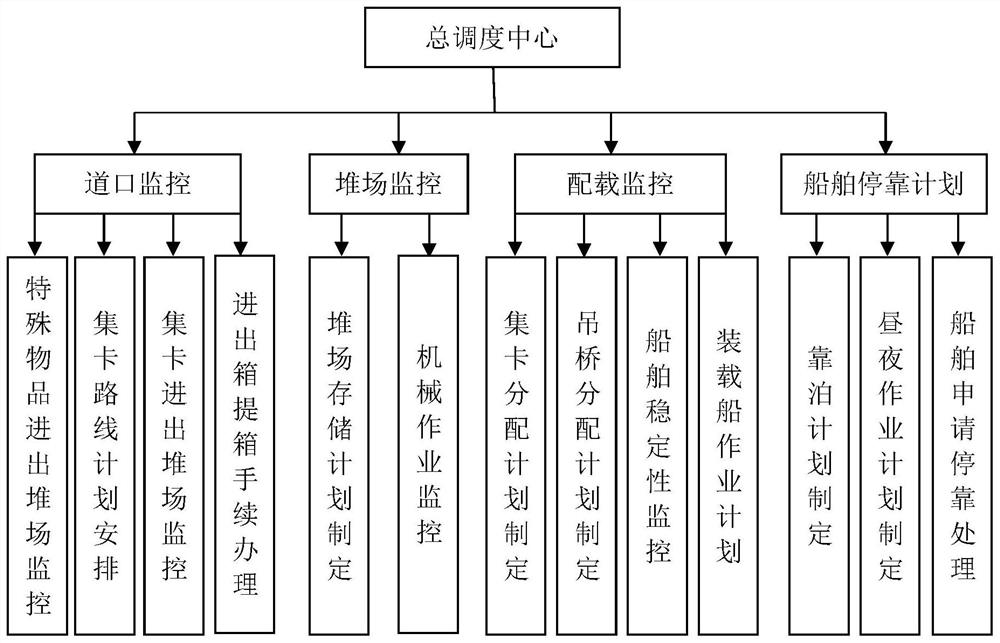

[0037] The container port production dispatching system of the present invention considers that the port production dispatching system requires strong information fluidity and adopts a centralized design mode, such as figure 1 As shown, it includes: ship docking planning module, stowage monitoring module, yard monitoring module and crossing monitoring module.

[0038] The main feature of the ship berthing planning module is to process ship berthing applications, formulate berthing and berthing plans and compile day and night production plans; Specific requirements such as moderate seaworthiness must also meet the requirements of the wharf production organization; the main function of the yard monitoring module is to allocate yard operation machinery reasonably and effectively, and ensure the improvement of the external service level of the wharf and other production of the wharf. Under the premise that the operation is not affected, all links on the site are coordinated, and v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com