Energy-saving synergistic anti-blocking method and system based on air preheater bypass flue

An air preheater, bypass flue technology, used in combustion methods, lighting and heating equipment, indirect carbon dioxide emission reduction, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] An energy-saving and efficiency-enhancing anti-clogging method based on the bypass flue of the air preheater. The air is heated by the bypass hot flue gas to a temperature above the acid dew point of the flue gas, and then sent to the cold end of the air preheater, which flows independently through the heat storage element to prevent the heat storage element from being clogged with dust.

[0052] The anti-blocking by bypassing the hot flue gas to heat the air above effectively overcomes the defects of the existing hot air circulation anti-blocking, and has significant advantages such as reducing the exhaust gas temperature, reducing the power consumption of the plant, and reducing the maintenance workload.

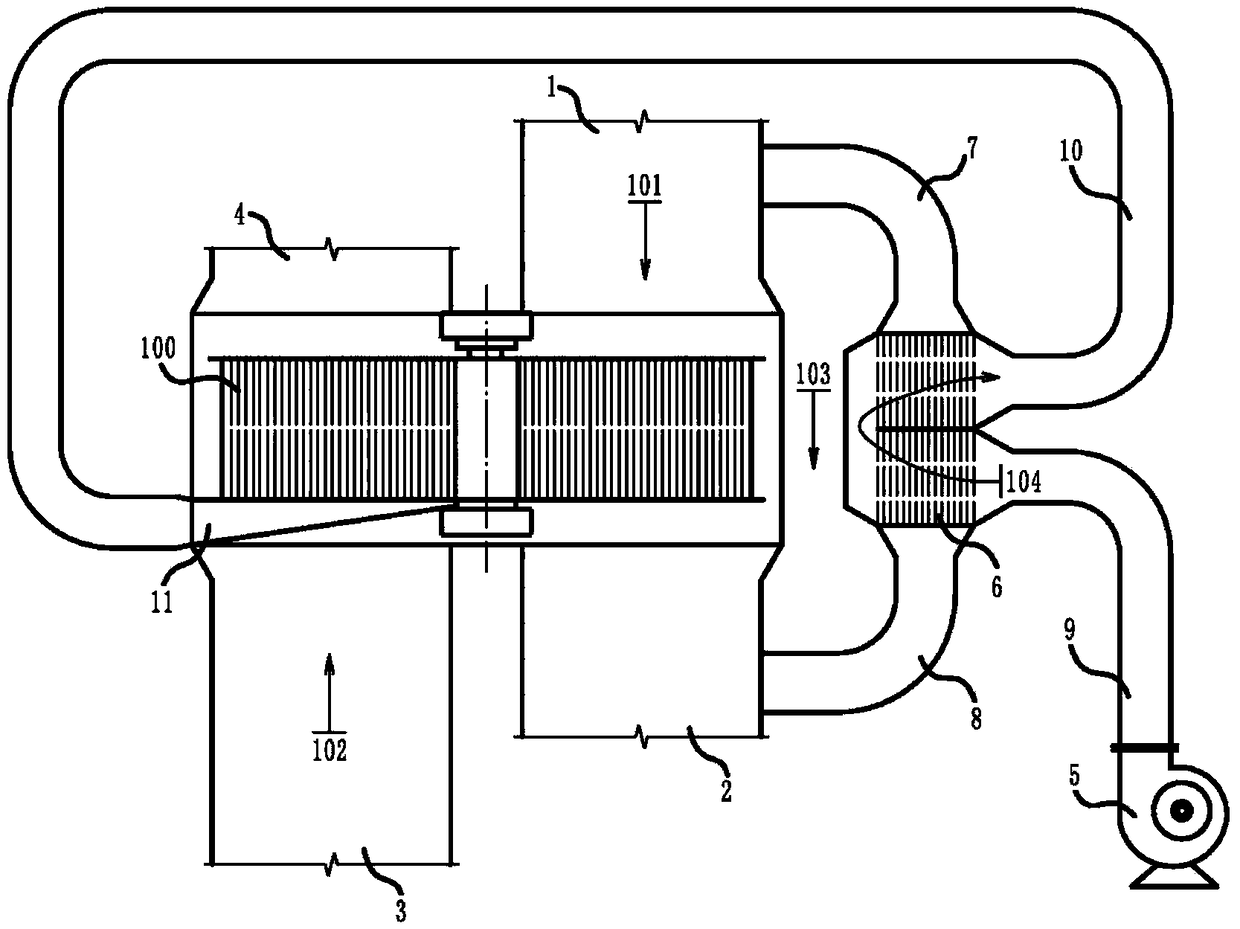

[0053] Such as figure 1 As shown, as an energy-saving and efficiency-enhancing anti-blocking system based on the air preheater bypass flue to realize the above method, it includes an air preheater and an inlet main flue and an outlet main flue arranged on the air pr...

Embodiment 2

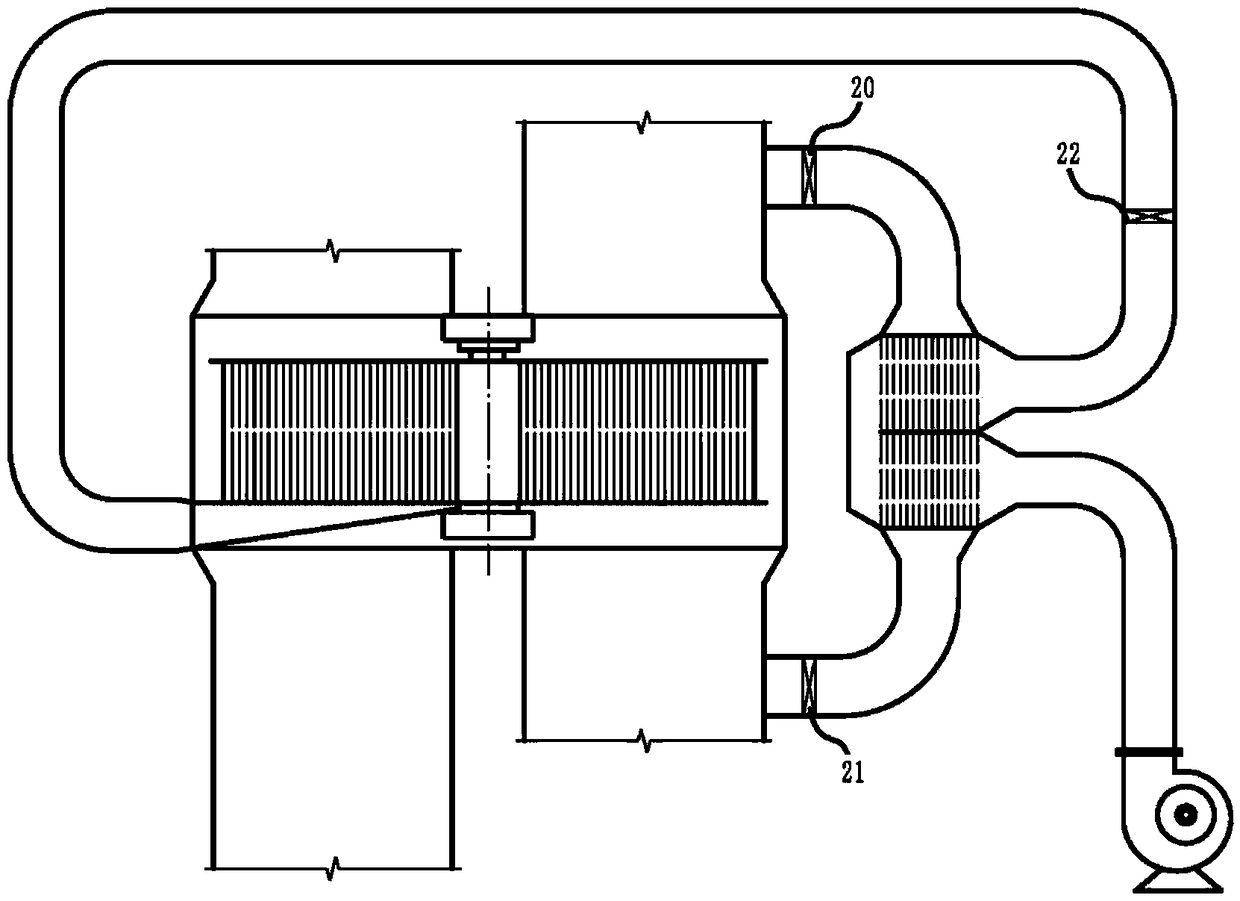

[0059] Such as figure 2 As shown, it is basically the same as Embodiment 1, the difference is: in order to facilitate the isolation and maintenance of the bypass heat exchanger, and at the same time adjust the flow rate of the bypass flue gas, a bypass flue gas baffle door is provided on the bypass inlet flue, and the bypass flue gas baffle door is There is a bypass smoke isolation door on the road exit flue, and a bypass air isolation door on the bypass outlet air duct.

Embodiment 3

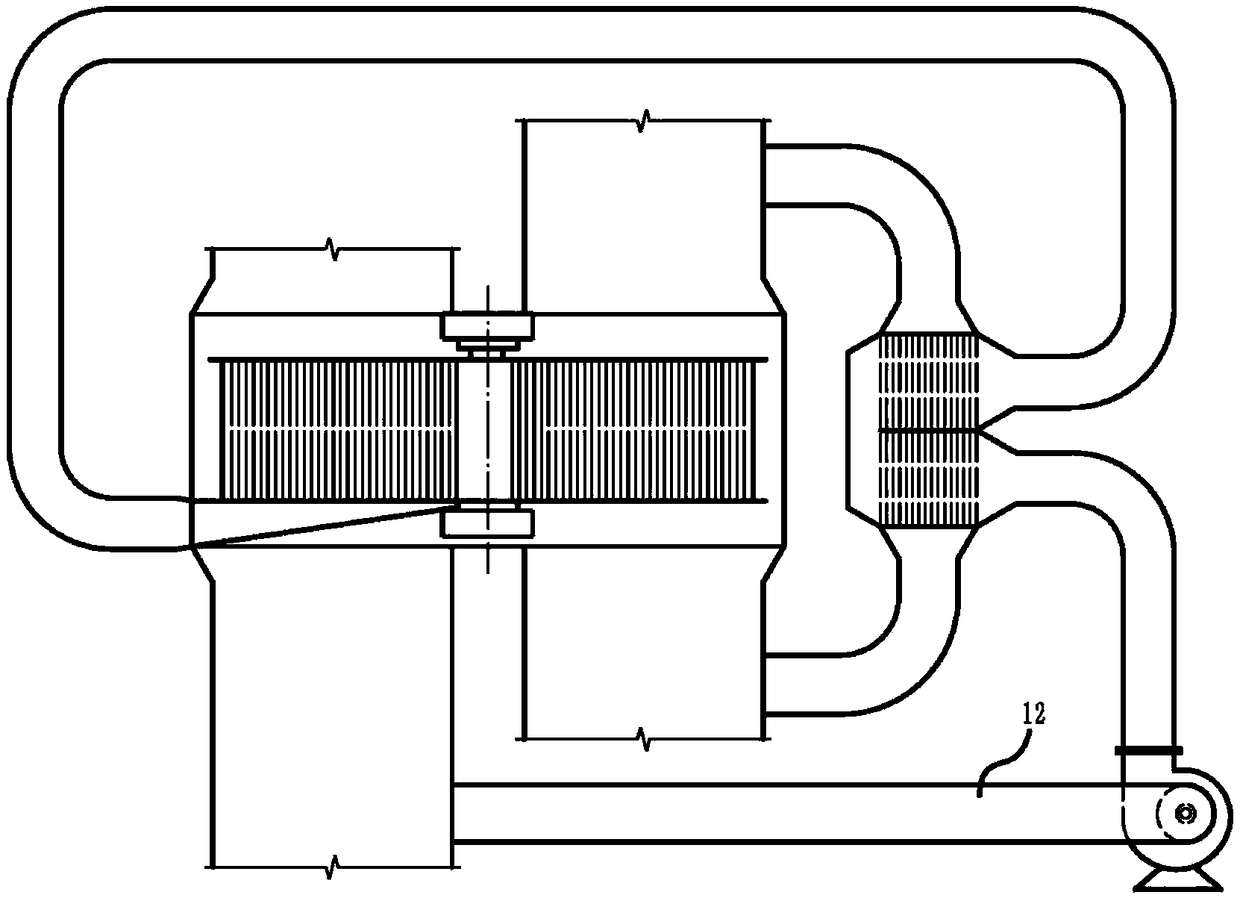

[0061] Such as image 3 As shown, it is basically the same as Embodiment 1, except that in order to save the power consumption of the anti-blocking ash fan, the inlet of the bypass anti-blocking ash fan is connected to the main air duct of the inlet through the bypass connection air duct.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com