Cam-type backlash-free precision positioning speed reducer

A precise positioning, cam-type technology, applied in the direction of mechanical equipment, belts/chains/gears, transmission devices, etc., can solve the problems of low positioning accuracy, gaps, backlash, etc., to achieve accurate action, simple structure, and high output accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

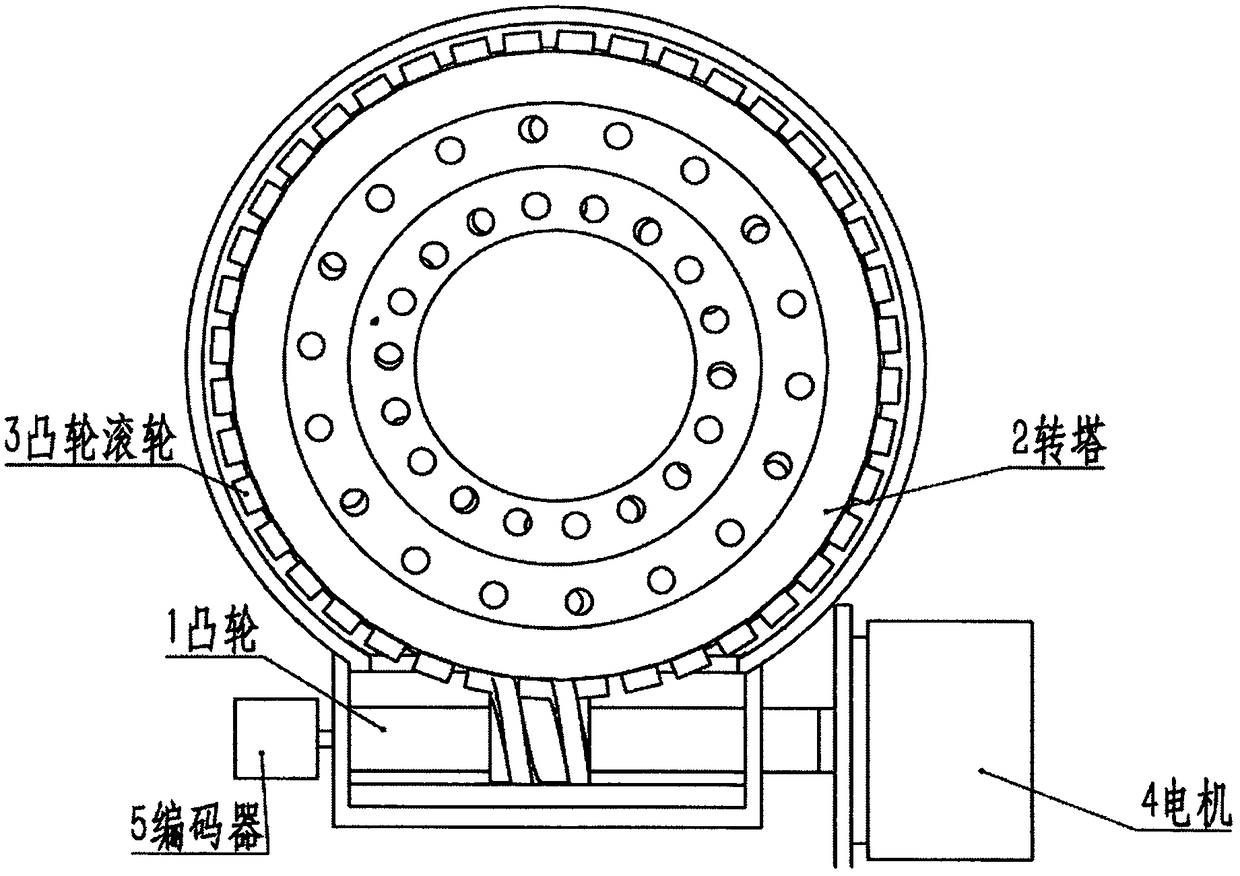

[0009] Cam-type backlash-free precise positioning reducer includes cam 1. cam roller 2. turret 3. motor 4. encoder 5. Cam 1. and motor 4. are linked to drive the cam roller 2 to rotate one circle. It moves along the motion curve of the cam, driving the turret to move along the curve of the cam 1. to move an angle, and the continuous rotation of the cam 1 drives the turret 3. Doing continuous circular motion, when the cam 1. rotates in the opposite direction, since the cam 1. and the cam roller 2. are meshed without backlash, the motion track of the cam 1. is transmitted to the turret 3 without error. The cam is connected with the motor, and the encoder is connected with the cam to control the rotation angle of the turret, so as to complete the precise positioning of the backlash-free transmission.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com