Horizontal axial wind following high-speed rotation wind power generator

A technology of wind generators and high-speed rotation, which is applied to wind turbines, wind turbines, and wind motor combinations in the same direction as the wind, and can solve problems such as loose slotting at the end of the gearbox, poor utilization of wind energy, and hidden dangers to personal safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

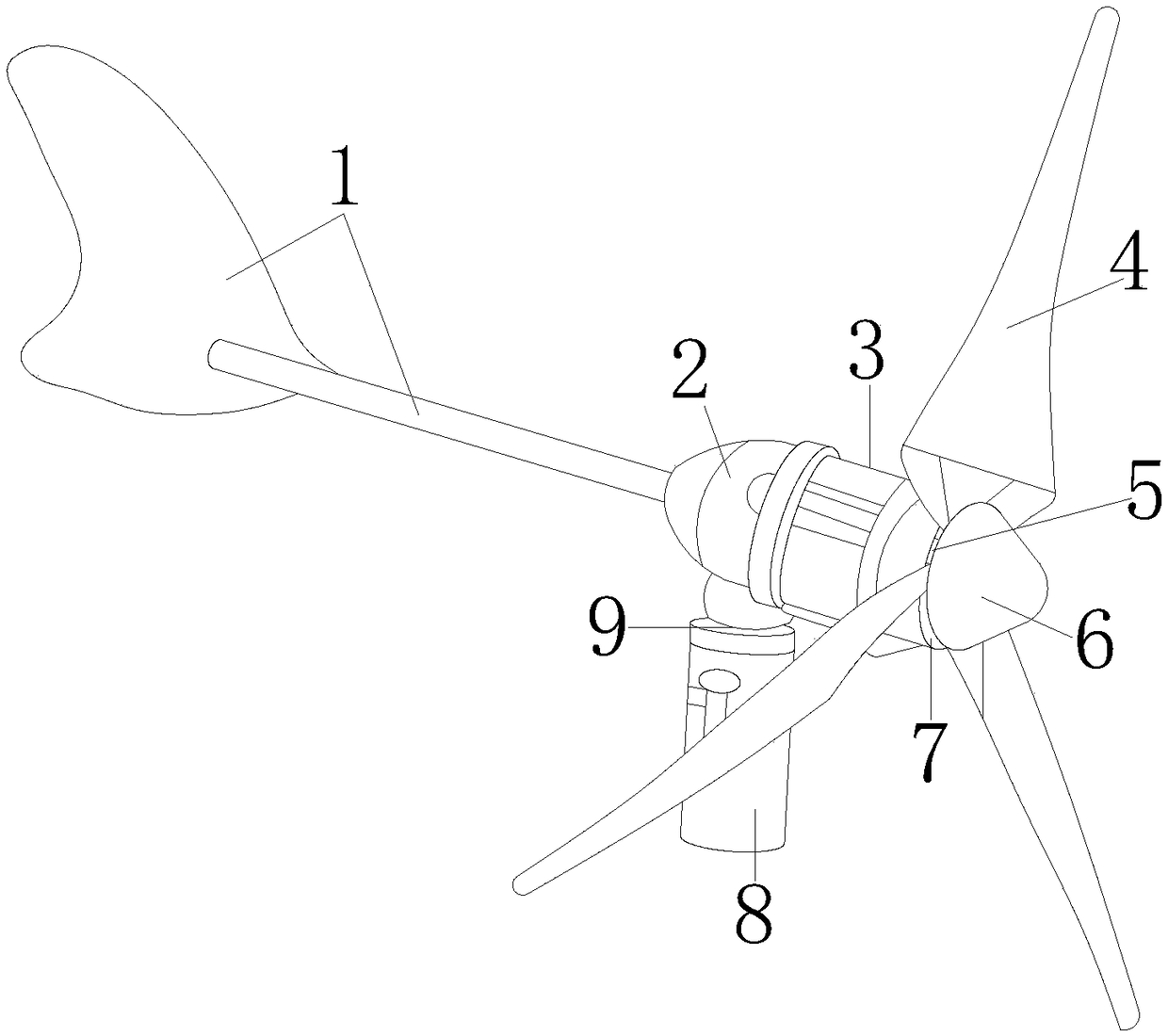

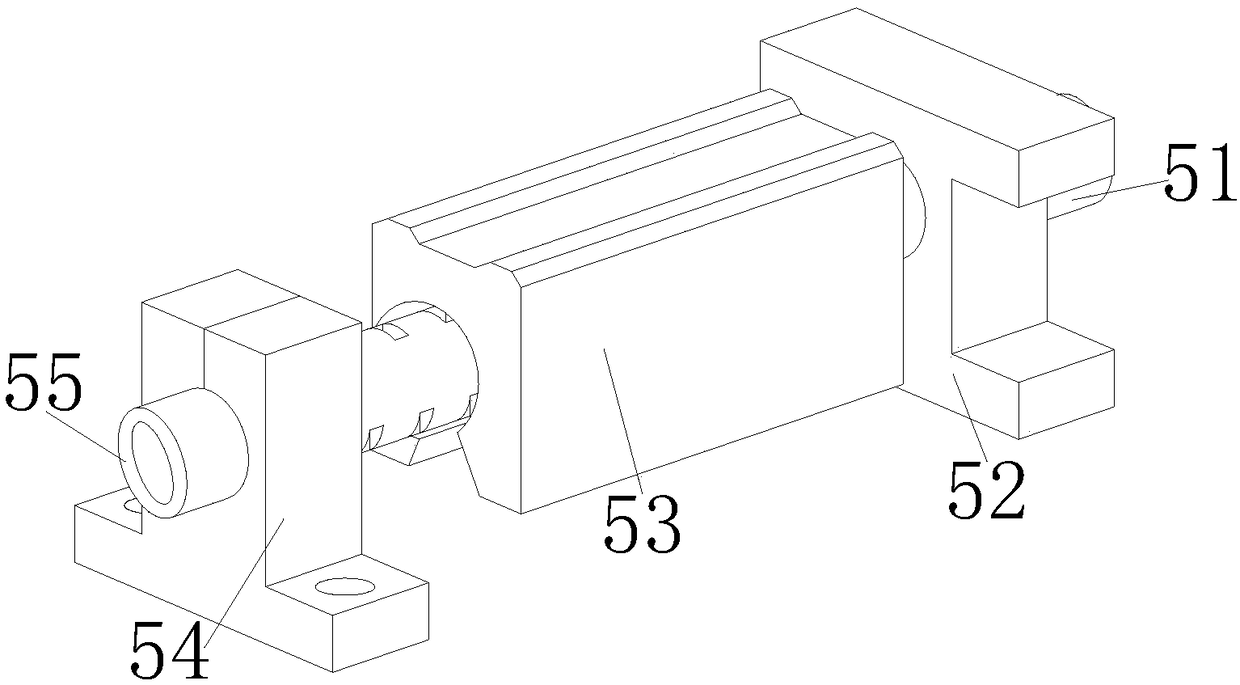

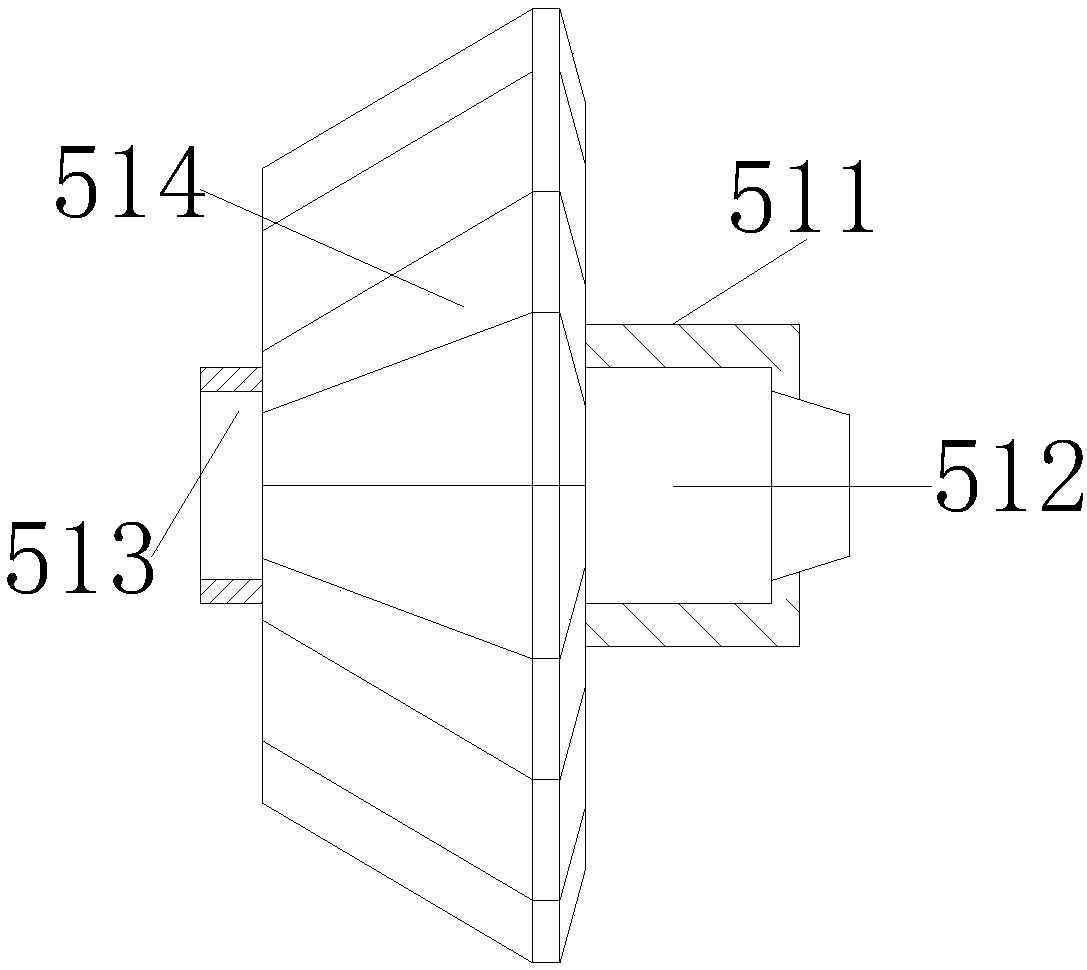

[0024] see Figure 1-Figure 7 , the present invention provides a high-speed rotating wind generator with a horizontal axis following the wind, its structure includes an empennage 1, a generator 2, a nacelle shell 3, a windmill blade 4, a blade navigation mechanism 5, a shroud 6, a hub 7, and a tower 8. The rotary shaft 9, the empennage 1 is horizontally installed in the center of the rear end of the nacelle shell 3 and is fixedly connected, and the inner rear of the nacelle shell 3 is provided with a generator 2 for fastening and buckling connection, and the windmill blades 4 are distributed and arranged around the guide The outer wall of the flow cover 6 is equally spaced, and the front end of the blade navigation mechanism 5 is fastened and embe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com