A melting gasifier and a process for treating gasifier ash based on it

A melting gasifier and ash slag technology, applied in the field of coal chemical industry, can solve the problems of poor environmental protection benefits, heavy burden on enterprises, high cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] Usually, the coal gasification slag content after standing still is water: 63.1%, ash: 74.81%, volatile matter: 2.81%, sulfur: 0.36% and fixed carbon: 8.26%.

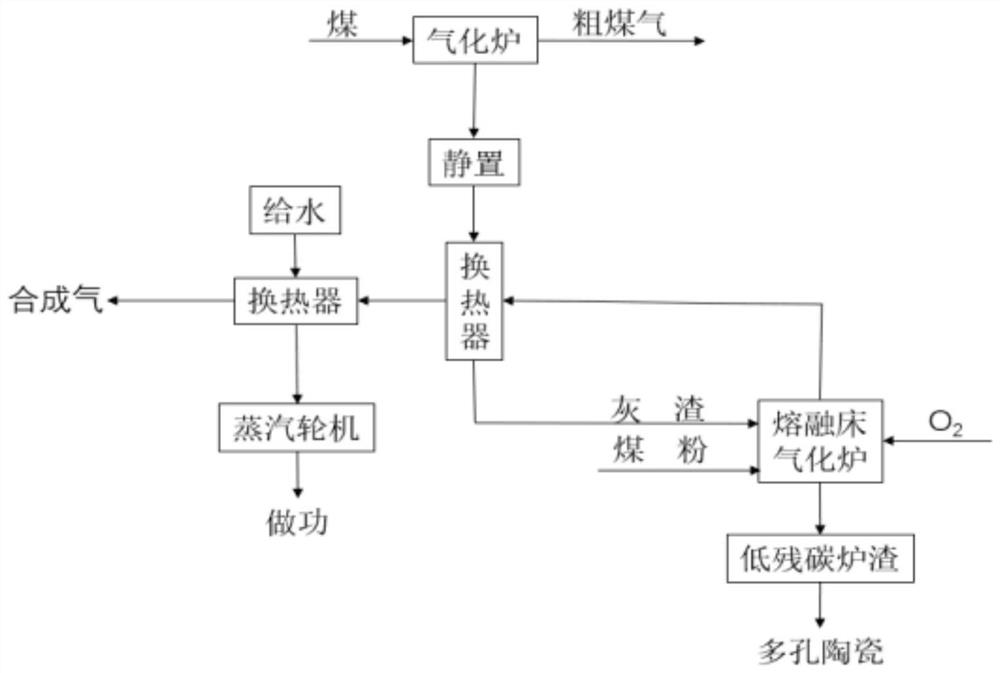

[0047] Present embodiment technological step is as follows:

[0048] 1) Stand still: After the ash from the gasifier is left standing in the buffer tank for 6-8 hours, its water content is about 60%. .

[0049] 2) Exchange heat between the ash with a water content of 60% and the high-temperature synthesis gas discharged from the top of the melter-gasifier, so that the temperature of the ash can rise to 1300° C., and at the same time achieve the purpose of reducing the temperature of the crude synthesis gas.

[0050] 3) Proportion the coal and the ash whose temperature has been raised to 1300°C, and then pass it into the melter gasifier with an appropriate amount of oxygen to carry out the oxidation reaction. The feed ratio of coal to ash is 1.87, and The ratio was 1.64. The process simulation process stipulate...

Embodiment 2

[0056] The gasification slag is mainly composed of SiO 2 、Al 2 o 3 , CaO and carbon residue, etc. The composition is very similar to that of glass-ceramics, so the ash from the gasification furnace is used to make glass-ceramic ceramics, and the molten material from the melting and gasification furnace is the molten glass frit, which is then shaped , annealing, cutting and other processes can be made into glass-ceramics. The process of making glass-ceramics is roughly: basic glass frit preparation-grinding-mixing-melting-clarification-forming-annealing-cutting-laying-sintering-polishing-packaging. Using this process in connection with the melting and gasifying furnace of the present invention will greatly reduce the production cost of glass-ceramics. The melting and gasifying furnace can be used as the melting process of the glass kiln, and the subsequent molding and annealing processes can be continuous. At the same time, glass-ceramic can produce different glass-ceramics ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com