Cargo-parachute separation mechanism after airdrop device entering water

A separation mechanism and equipment technology, which is applied in the direction of parachutes, aircraft parts, emergency equipment, etc., can solve the problems of low success rate of material parachute separation and slow separation speed of material parachute, and achieve the effect of fast separation, improved reliability and fast separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

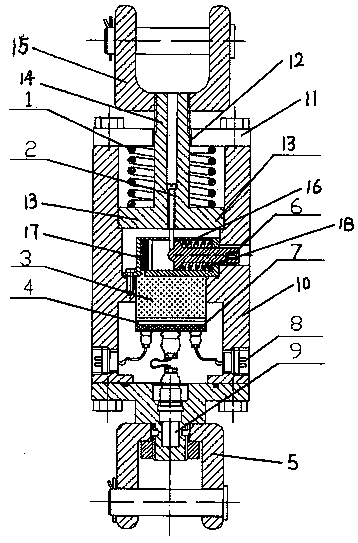

[0010] The present invention is described in detail below in conjunction with accompanying drawing:

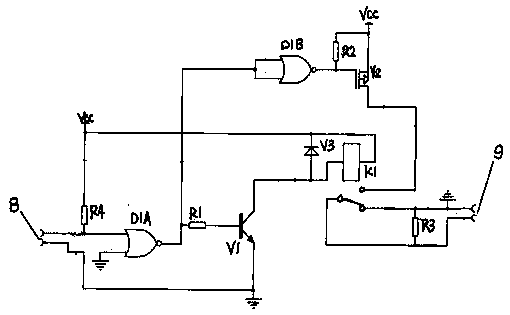

[0011] An umbrella separation mechanism for airdrop equipment after entering water, comprising a piston cylinder 10, a cylinder cover 11 is arranged on the top of the piston cylinder 10, a piston rod piercing hole 12 is arranged at the center of the cylinder cover 11, and a piston rod piercing hole 12 is arranged on the piston cylinder. The top in 10 is provided with piston 13, is provided with piston rod 14 on the upper top surface of piston 13, and piston rod 14 is fixedly connected together with parachute bottom frame 15 after passing piston rod piercing hole 12, between piston 13 and A spring 1 is arranged between the cylinder covers 11, a thermal battery starting pin sleeve 16 is arranged in the piston cylinder 10 below the piston 13, and a thermal battery starting pole plate 17 is arranged at the left end of the thermal battery starting pin sleeve 16. The inner right end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com