Plywood transport vehicle

A technology of transport vehicles and plywood, applied in the field of transport vehicles, can solve the problems of complex structure of plywood transport vehicles, friction and collision of plywood, increased production costs, etc., and achieve the effect of preventing relative rotation, reducing shaking, and high utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

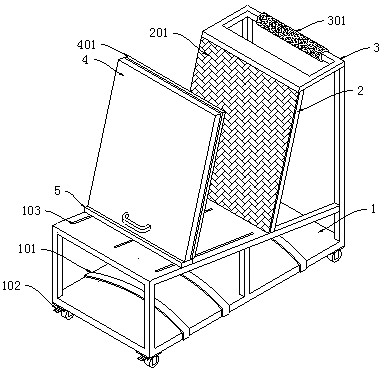

[0018] Example: such as figure 1 and figure 2 As shown, a plywood transport vehicle of the present invention includes a car body 1, a support plate 2, an armrest plate 3 and a pressing plate 4, the armrest plate 3 is fixedly arranged on the top of the car body 1, and the gap between the car body 1 and the armrest plate 3 There is also a support plate 2 fixedly arranged between them, the pressing plate 4 is arranged on the top of the car body 1, the bottom end of the pressing plate 4 is fixedly connected with the top of the sliding connection seat 5, and the bottom of the sliding connecting seat 5 is connected with the top of the car body 1. Flexible connection, one side of the support plate 2 is fixed with a soft plate 201, one side of the compression plate 4 is equipped with a shock absorber 401, and several shock absorbers evenly distributed between the compression plate 4 and the shock absorber 401 The spring connection, through the provided car body 1, support plate 2 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com