Control system and control method of tilting type butt autogenous grinding machine

A control system and self-grinding machine technology, which is applied to the parts of grinding machine tools, grinding automatic control devices, manufacturing tools, etc. Safe and reliable, reduce labor intensity and improve work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited by the embodiments.

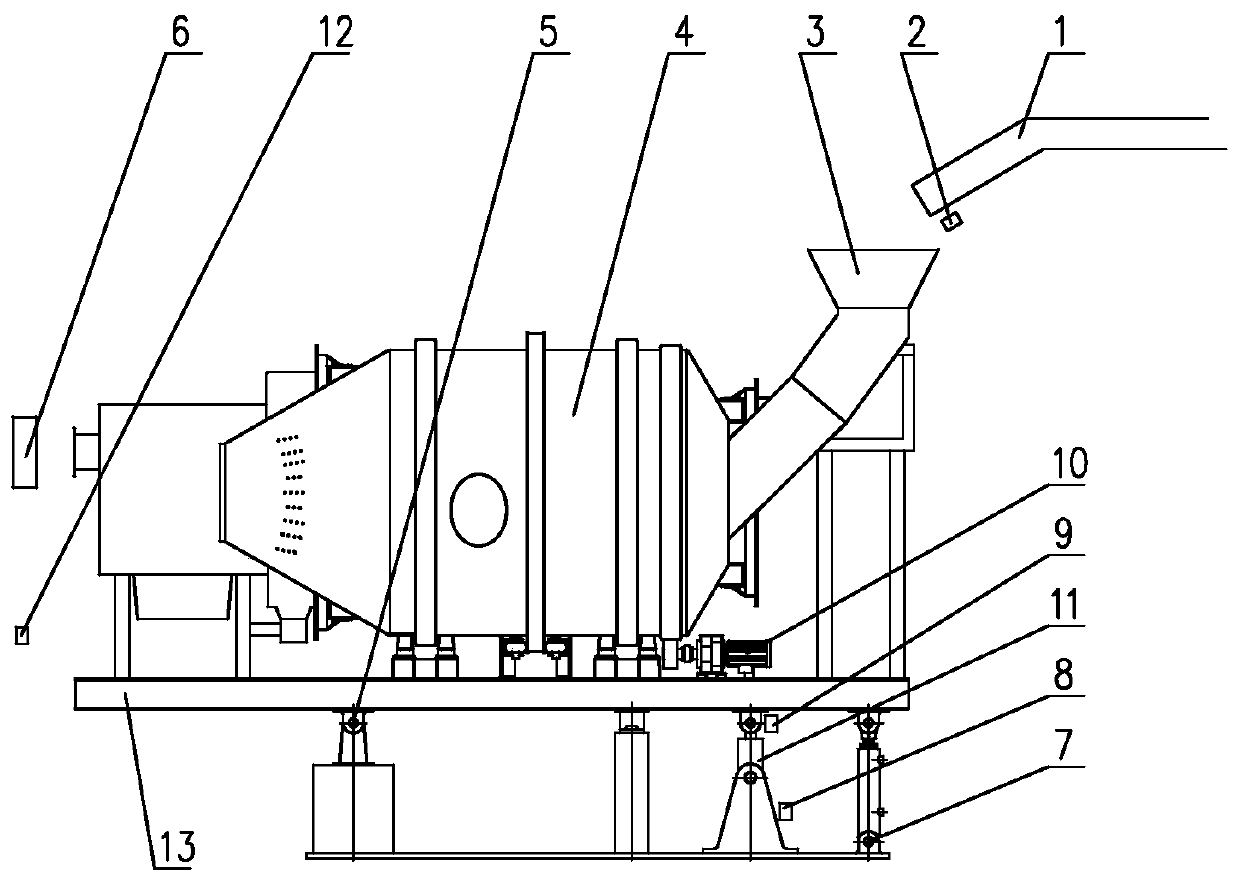

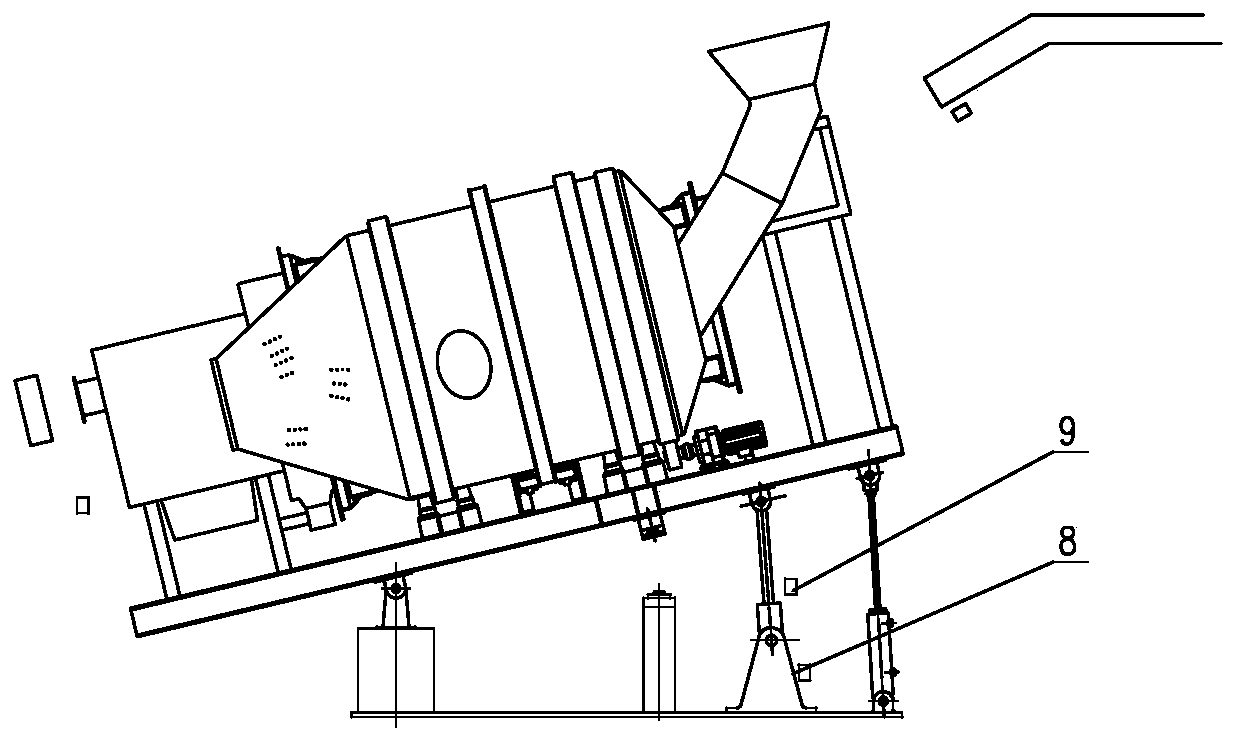

[0036] Such as Figure 1-Figure 2 As shown, the control system of the tilting aluminum electrolytic residual electrode self-grinding cleaning machine of the present invention mainly includes: a feeding device 1, a meter 2, a feeding device 3, a cleaning drum 4, a bearing seat 5, an air induction system 6, and an oil cylinder 7. No. 1 limit switch 8, No. 2 limit switch 9, gear motor 10, guide sleeve 11, emergency brake switch 12, base plate 13 and PLC controller, etc. The specific structure is as follows:

[0037] The top of base plate 13 is provided with cleaning drum 4 and deceleration motor 10, and the output end of deceleration motor 10 stretches to the feeding end in cleaning drum 4; Oil cylinder 7 and guide sleeve 11 are hinged with base plate 13 respectively...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com