Automatic production equipment of transformer magnetic ring and magnetic ring chamfering device

A chamfering device and magnetic ring technology, which is applied in the manufacture of inductors/transformers/magnets, metal processing equipment, grinding/polishing equipment, etc., can solve the problems of not greatly improving efficiency and quality, high labor intensity, and failure to achieve automation, etc. problems, to achieve the effect of high chamfering efficiency and quality, and to ensure the consistency of chamfering quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the present invention more comprehensible, it will be described in detail with the drawings as follows.

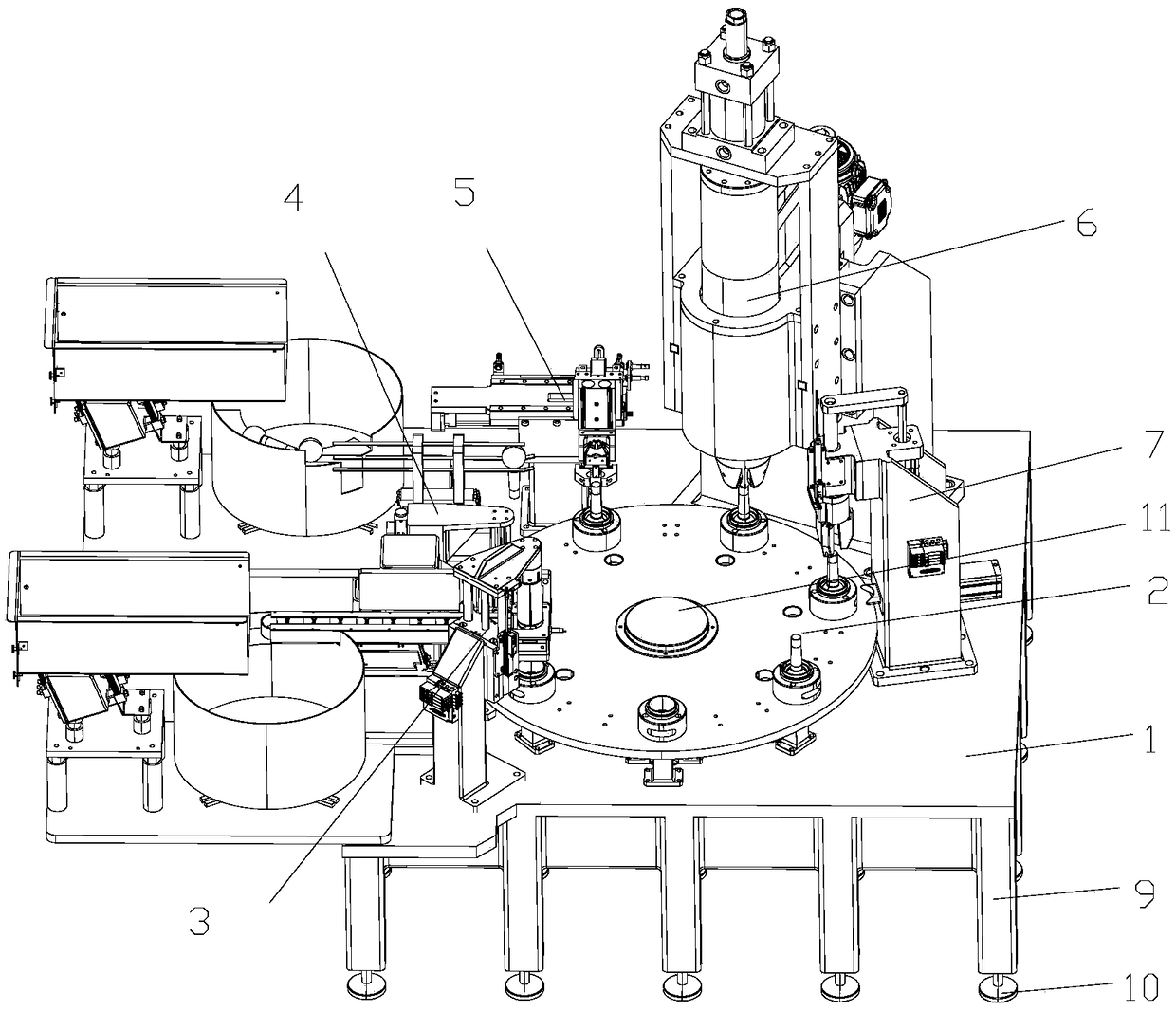

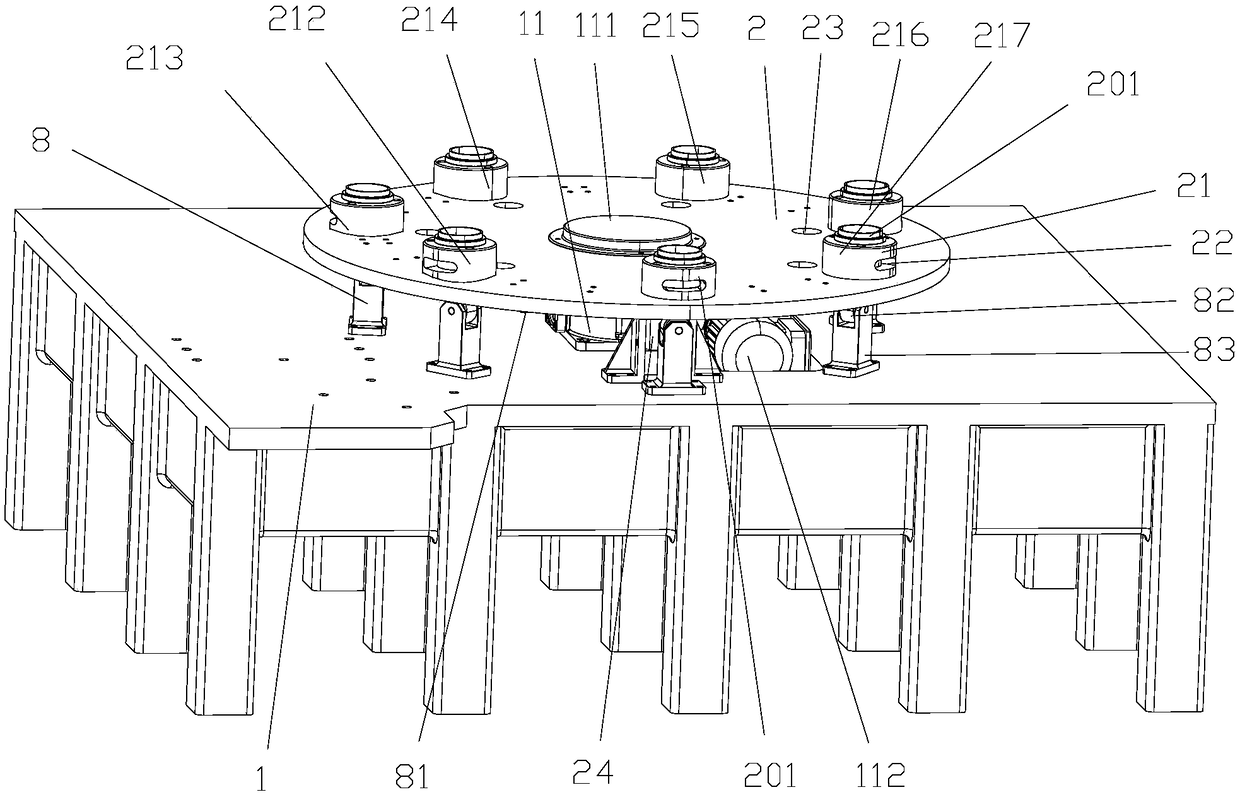

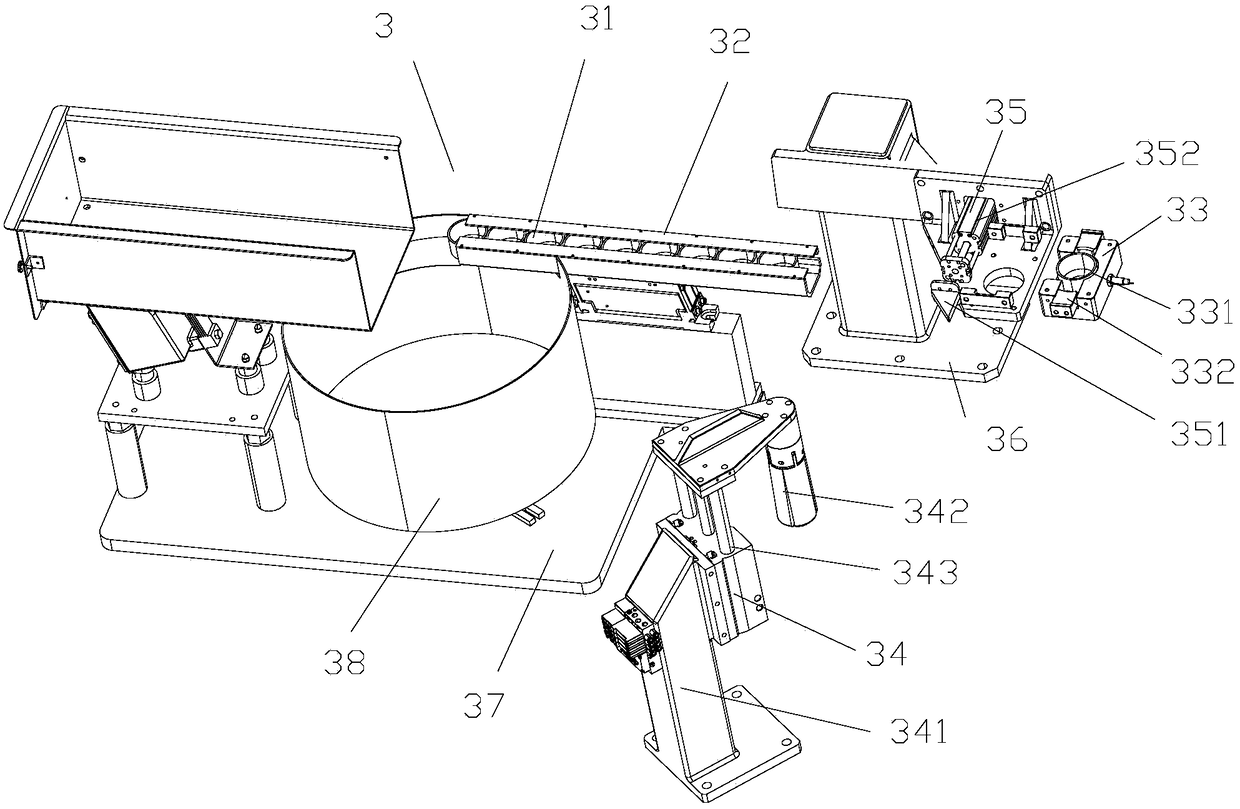

[0024] Such as figure 1 As shown, an automated production equipment for a transformer magnetic ring, the equipment includes a support cabinet 1, a feeding mechanism 2, a conveying mechanism 3, a first chamfering mechanism 4, a conveying and turning mechanism 5, a second chamfering mechanism 6 and a discharge Institution 7. The feeding mechanism 2 is arranged on the front side of the supporting cabinet 1, the first chamfering mechanism 6 is arranged on the right part of the supporting cabinet 1, and the magnetic ring is conveyed by the feeding mechanism 2 through the conveying mechanism 3 to the first chamfering mechanism 4 for the first side inverting After the first chamfering mechanism 4 is chamfered, it is transported to the second chamfering mechanism 6 through the conveying and turning mechanism 5 for the second side chamfering. The second chamfer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com