Dust collecting cup assembly module and dust cleaner

A technology for assembling components and dust cups, which is applied to vacuum cleaners, suction filters, cleaning equipment, etc., and can solve the problems of easy falling off of dust cups and few contact points

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

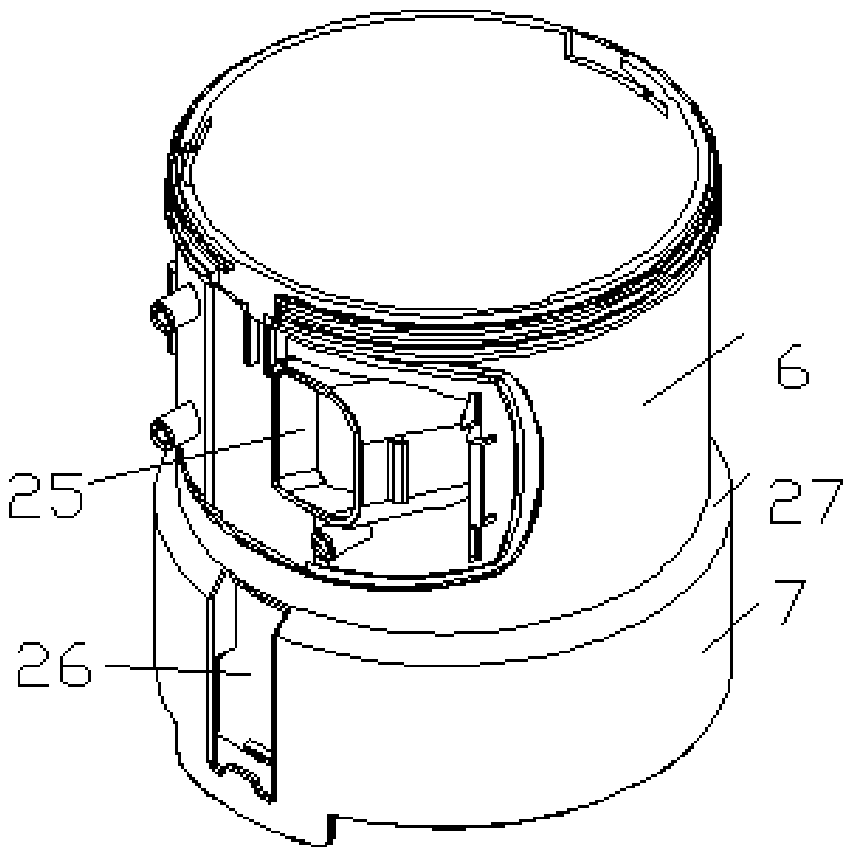

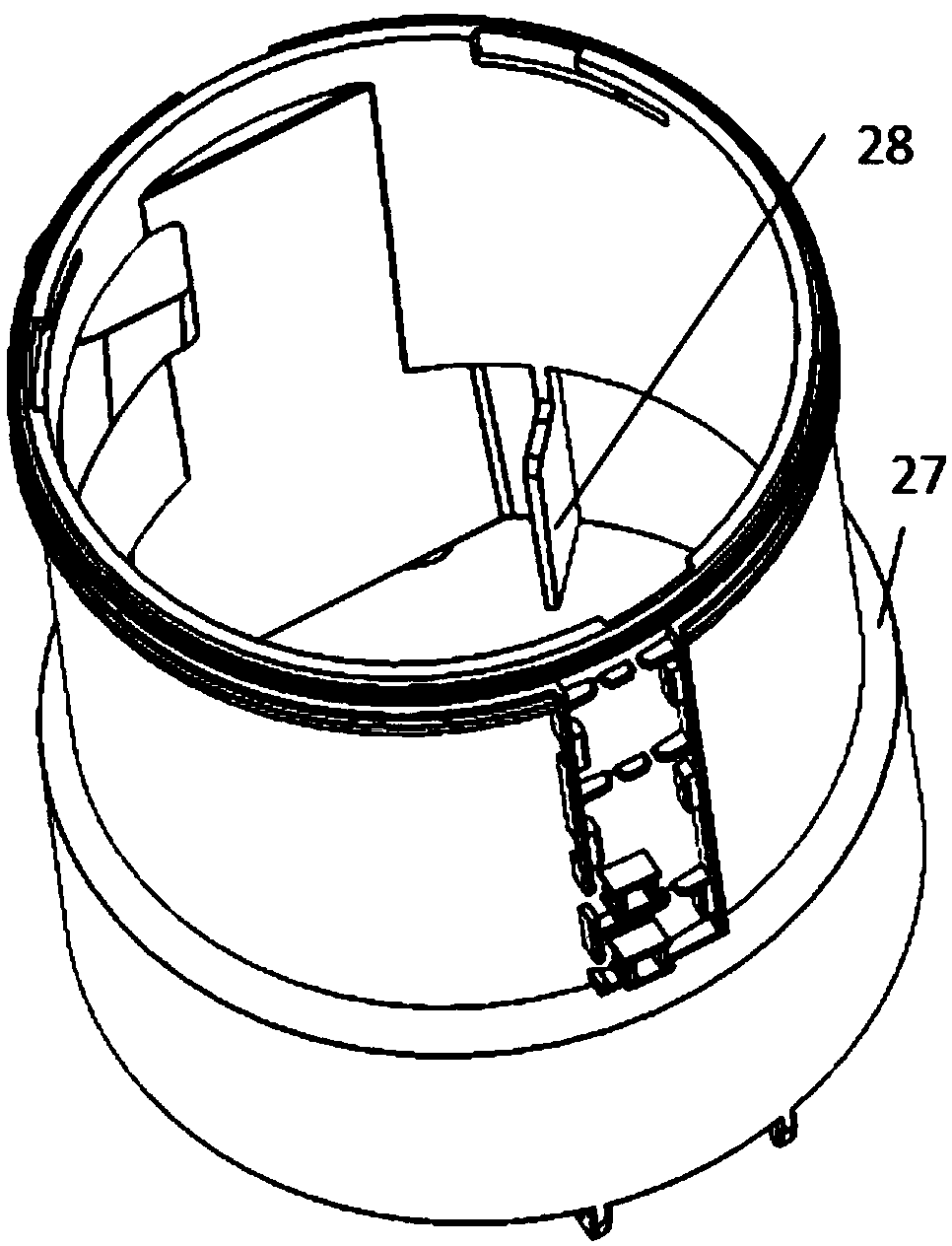

[0050] Such as Figure 1 to Figure 4 As shown, the assembly structure of the dust collection cup provided by the present invention includes: a dust collection cup 21, the dust collection cup 21 includes a first cup body 6 and a second cup body 7 arranged in the vertical direction;

[0051] A slope 27 is provided between the first cup body 6 and the second cup body 7, and the diameter of the second cup body 7 is larger than the diameter of the first cup body 6;

[0052] The first cup 6 is provided with a dust inlet 25 , and the second cup 7 is provided with a dust shield 28 .

[0053] In the assembly structure of the dust collection cup provided by the present invention, a slope 27 is provided between the first cup body 6 and the second cup body 7 , and the diameter of the second cup body 7 is larger than that of the first cup body 6 diameter; by setting the first cup body 6 and the second cup body 7, the dust collection cup 21 can be clearly divided; the selected diameter of ...

Embodiment 2

[0067] Existing vacuum cleaners are inhaled from the dust suction port and discharged from the air exhaust port of the main machine, and there are many sundries and dust when the air is exhausted, so that the cleaning effect is not good.

[0068] Such as Figure 5 to Figure 7 As shown, the structure of the main body cover 1 provided by the present invention includes a main cover housing 31 and a motor cavity 32;

[0069] A plurality of exhaust holes 36 are provided on the side wall of the main cover housing 31 , and an exhaust filter chamber is provided between the main cover housing 31 and the motor cavity 32 ;

[0070] An exhaust filter layer is arranged in the exhaust filter cavity, and the exhaust filter layer is arranged corresponding to the exhaust hole 36 .

[0071] In the structure of the main body cover 1 provided by the present invention, an exhaust filter layer is arranged in the exhaust filter cavity, and the exhaust filter layer is set corresponding to the exhaus...

Embodiment 3

[0085] The dust collecting cup 21 of the existing vacuum cleaner is assembled along the vertical direction or the front and rear horizontal directions. However, there are too few contact points in the above two assembly methods, so that the dust cup 21 is easy to fall off after assembly.

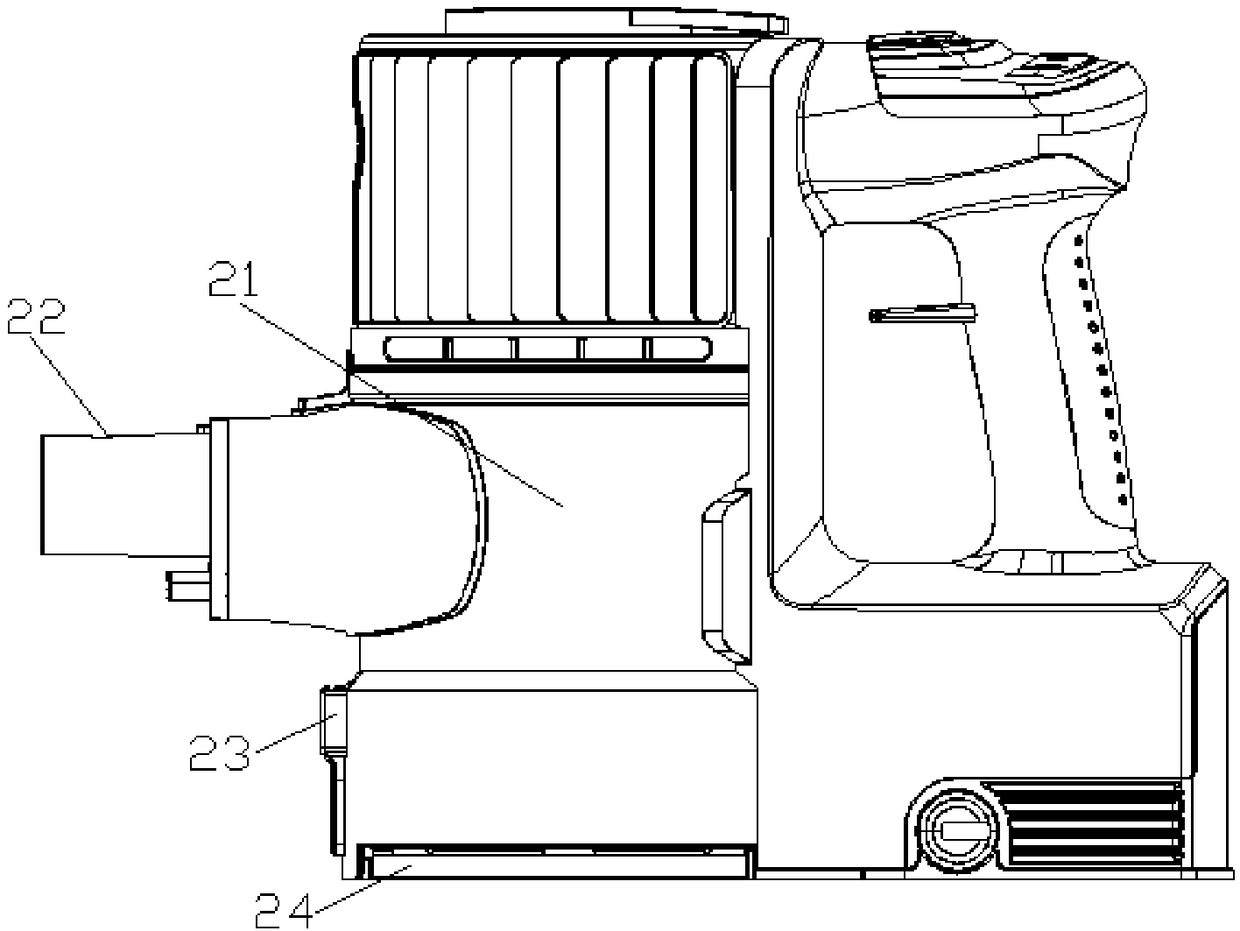

[0086] Such as Figure 8 to Figure 11 As shown, the dust collection cup assembly assembly provided by the present invention includes a dust collection cup 21 and a main body cover 1, and the main body cover 1 is arranged above the dust collection cup 21;

[0087] An assembly card slot 8 is provided on the top inner wall of the dust collection cup 21, and a card position 9 is provided in the assembly card slot 8;

[0088] The outer wall of the bottom of the main body cover 1 is provided with a protrusion 12, and the protrusion 12 is provided with a locking slot 13 corresponding to the locking position 9, and the locking position 9 can be inserted into the locking slot 13 Inside.

[0089] I...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com