A New Type of Fiberglass Ball Nut

A glass fiber reinforced plastic, spherical technology, applied in the direction of nuts, threaded fasteners, washers, etc., can solve the problems of heavy supporting structure, increase construction difficulty, easy to break, etc., achieve convenient cutting and processing, good fastening effect, improve The effect of performance and strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

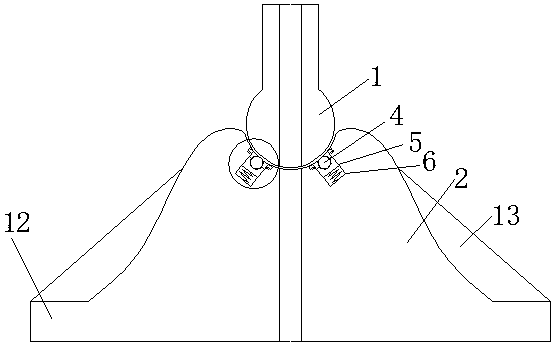

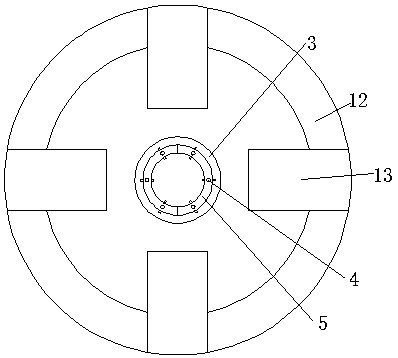

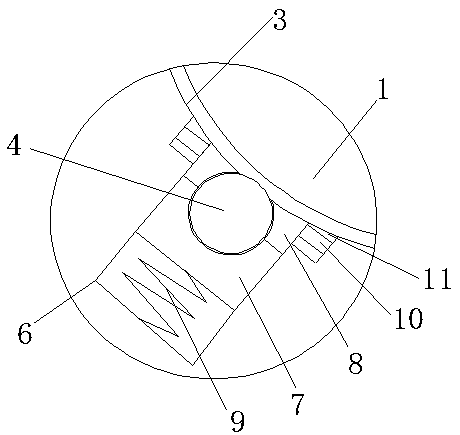

[0016] The preferred technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0017] As shown in the figure, a novel fiberglass spherical nut of the present invention includes a nut body 1 and an arc-shaped gasket 2 arranged below the nut body 1. One end of the nut body 1 is set as a protruding spherical surface, and the other end is set as a column. , the arc-shaped gasket 2 is arranged at one end of the spherical surface of the nut body 1, and an arc-shaped recess 3 is arranged in the middle of the arc-shaped gasket 2. The shape of the arc-shaped recess 3 is adapted to the spherical surface of the nut body 1, and the A ring of balls 4 is arranged on the arc-shaped recess 3 of the gasket 2 , and the ring of balls 4 is installed on the annular base 5 , and the annular base 5 is installed on the arc-shaped recess 3 .

[0018] Preferably, the annular base 5 is installed in the inclined groove 6 on the arc-sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com