Drag cable connection process method

A process method and technology for dragging cables, which are applied in the directions of connections, circuits, electrical components, etc., can solve problems such as hidden safety hazards for operators, expensive dragging cables, and safety accidents.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

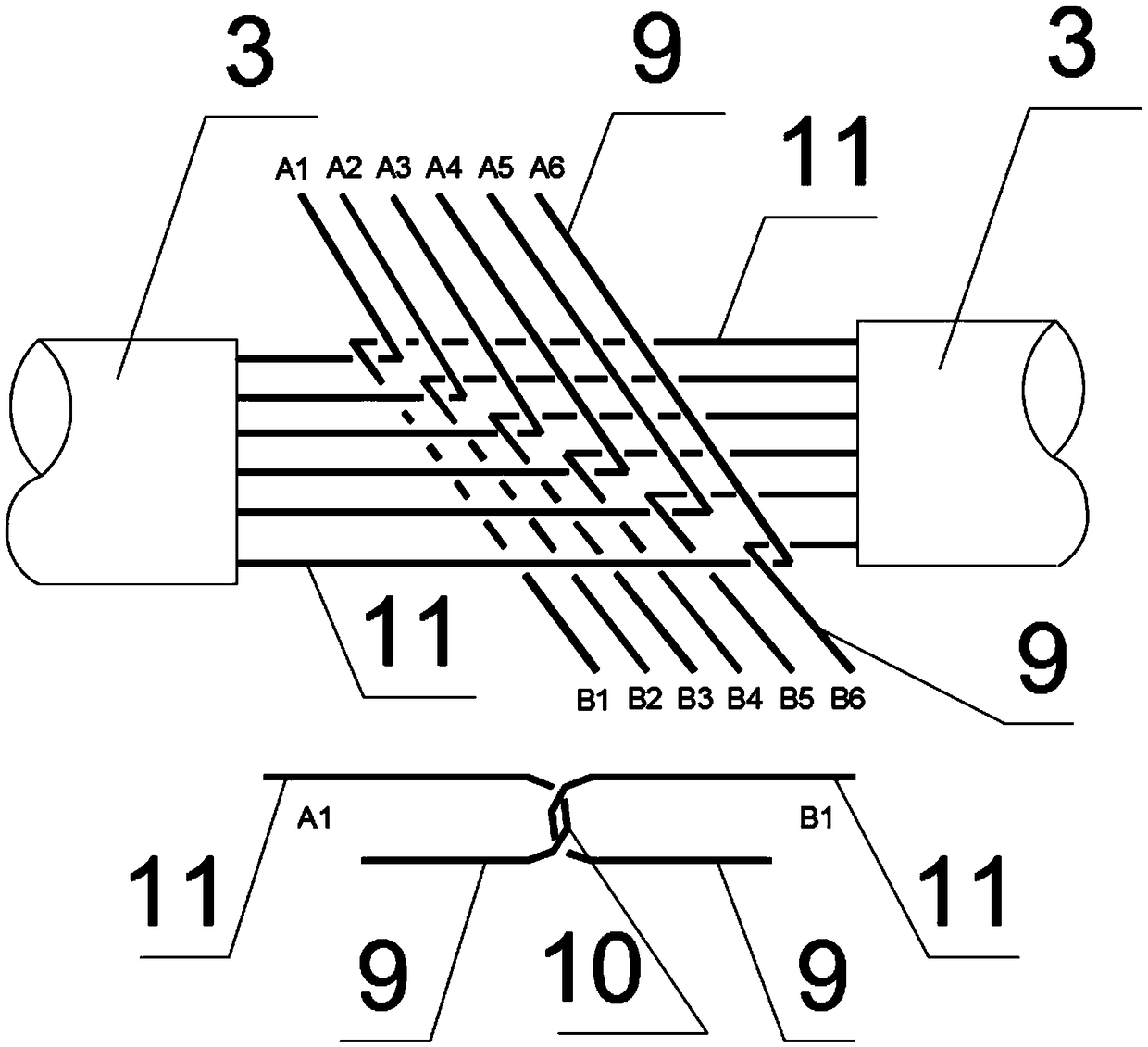

[0020] The following is a detailed description of the dragging cable connection process in conjunction with an embodiment. This embodiment is only one of the implementations of the process, and is not the only implementation. Therefore, this embodiment cannot be understood as claiming protection for the present invention. limitation of the scope of implementation.

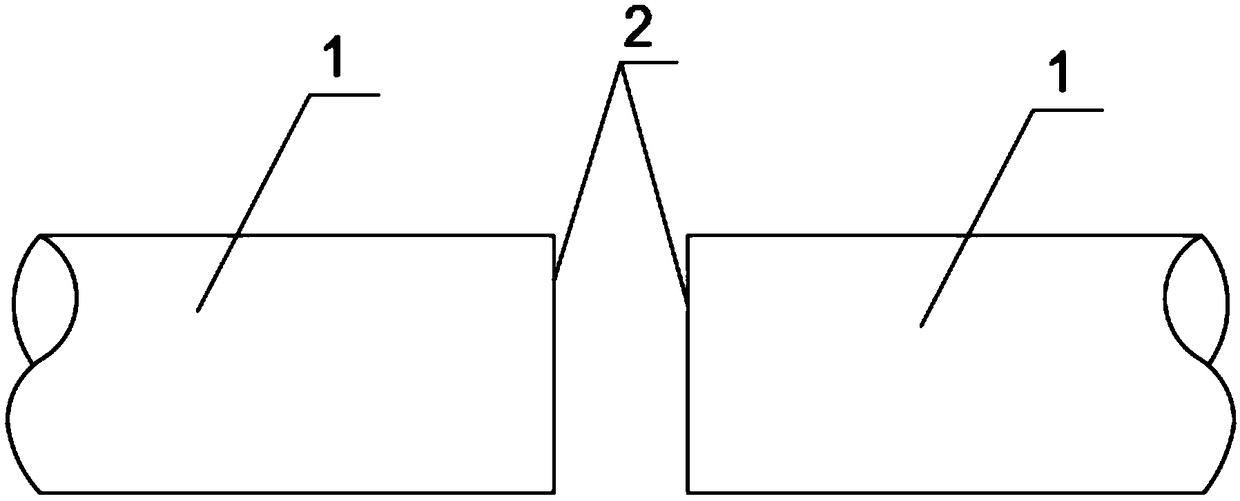

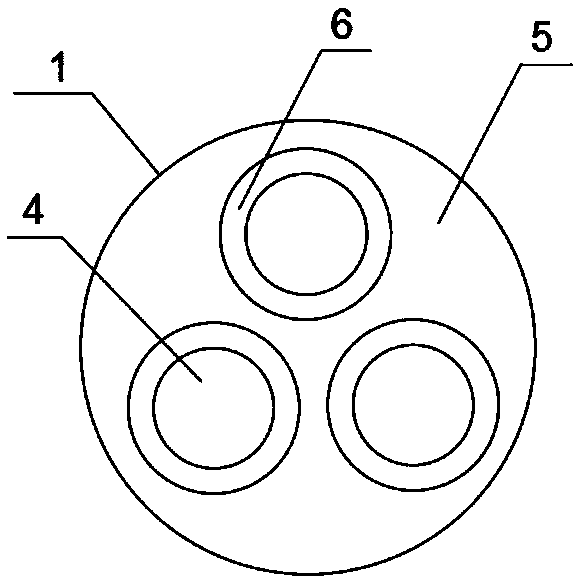

[0021] The connection process method of this embodiment is: earlier the outer layer insulating skin (52) of cable (1) two severed ends (2) is stripped off a section of 40cm length, exposes each phase of about 40cm length in the cable (1). Wire core (3); then the inner insulation skin (6) of each phase wire core (3) of the exposed 40cm length is stripped off a section of about 20cm length, and the conductor wire (4) in the phase wire core exposes a section of 20cm length Then each phase core (3) is connected respectively, and the connection of a single phase core (3) includes the following steps:

[0022] 1. Divide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com