Quick double-sided plug-in device

A plug-in device, double-sided technology, applied in the direction of assembling printed circuits, electrical components, electrical components, etc. with electrical components, can solve the problems of high defect rate, poor alignment accuracy, low efficiency of double-sided plug-in, etc., to achieve practicality. Strong, improve work efficiency, ensure consistent insertion length and the effect of alignment accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

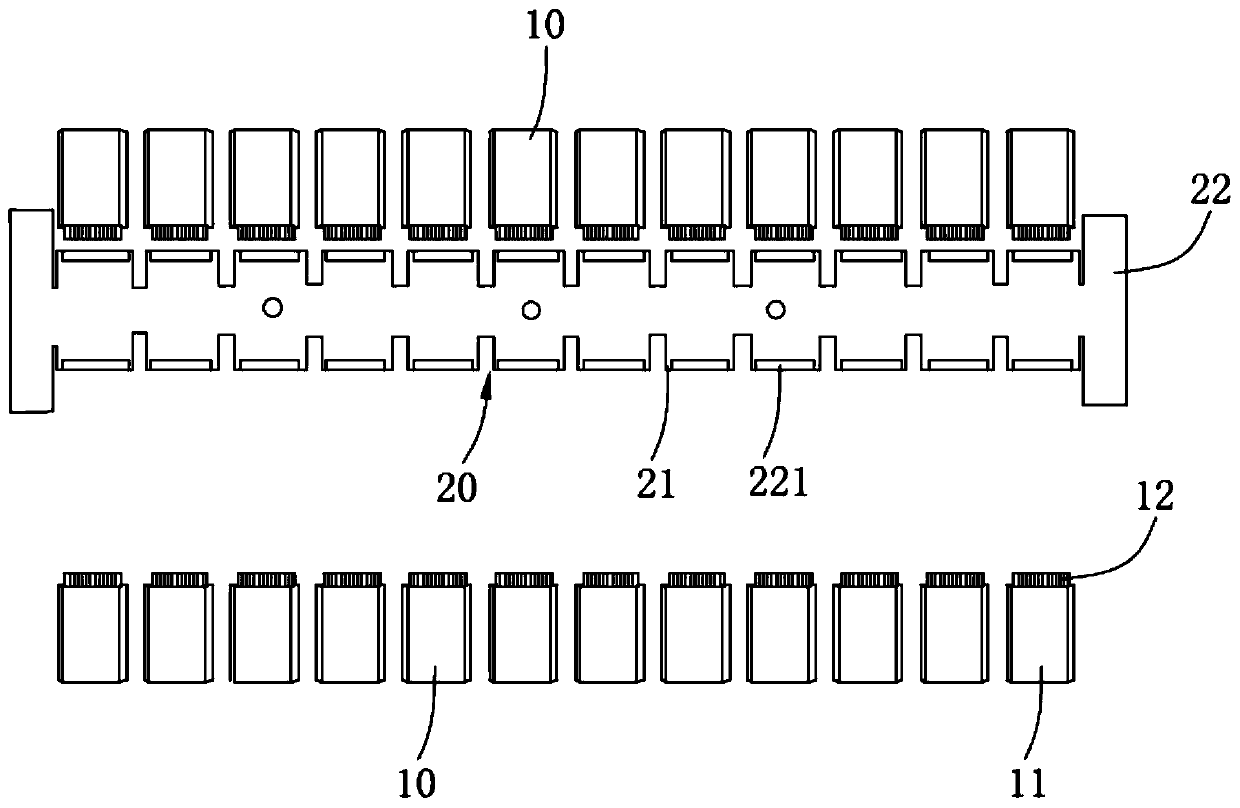

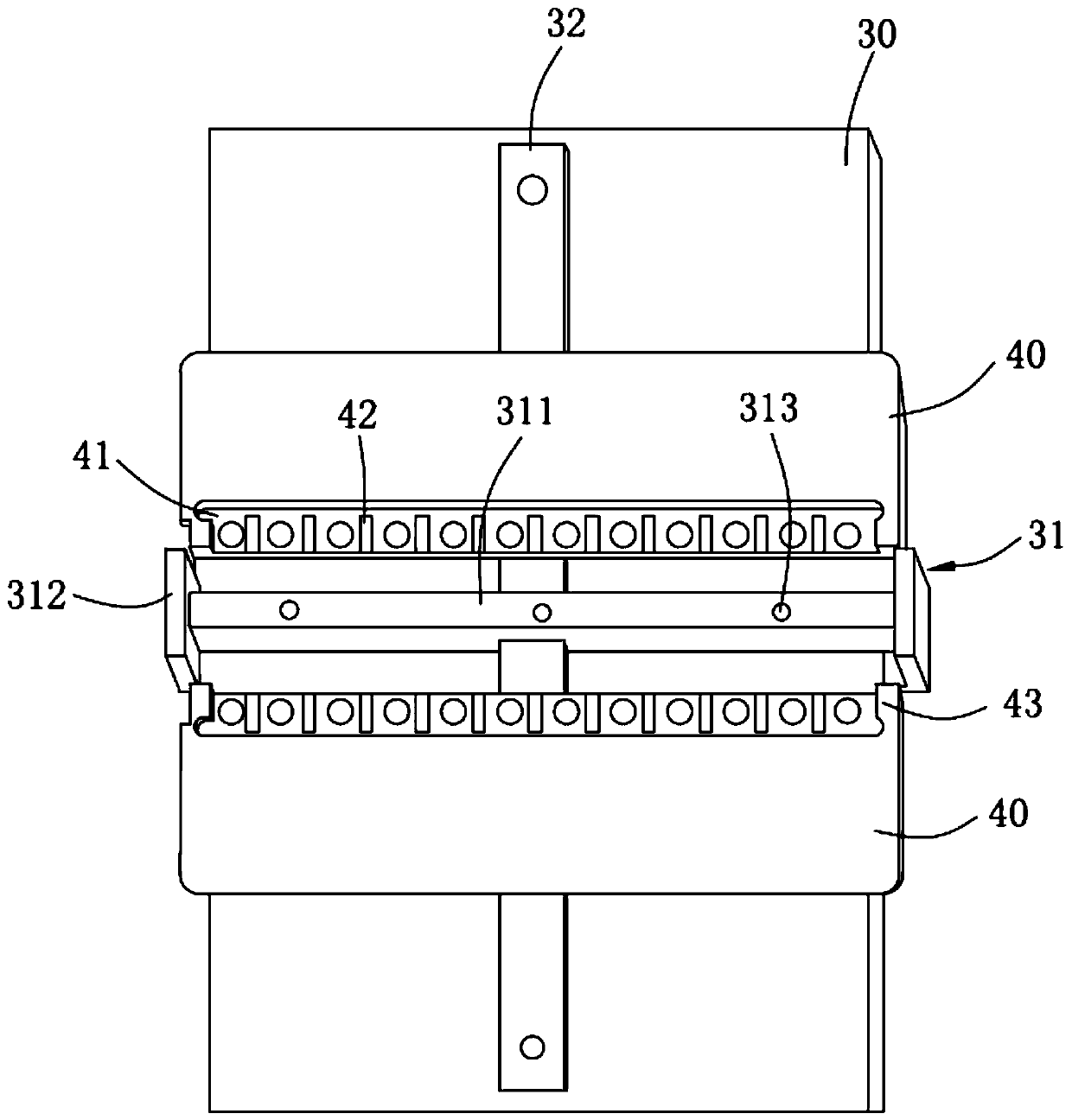

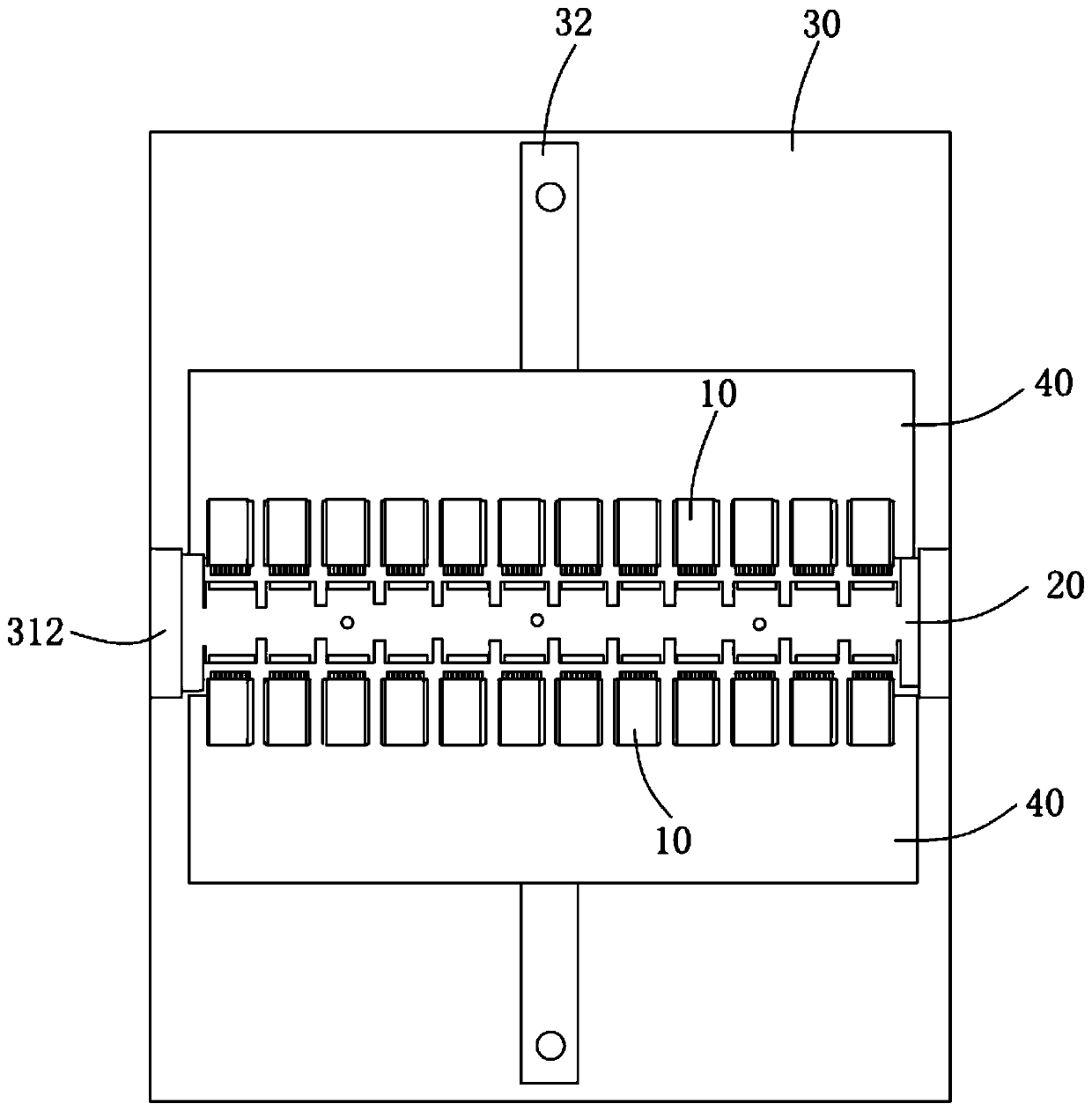

[0022] Such as Figure 1 to Figure 3 As shown, the present invention provides a fast double-sided plug-in device, which can insert multiple components 10 onto the PCB 20 at one time. The PCB 20 is extended in a strip shape, and the PCB 20 is provided with a plurality of insertion parts 21 on two opposite sides in the extending direction, and the plurality of insertion parts 21 on the same side are evenly arranged in a row. The upper and lower surfaces of the plug-in part 21 are provided with slots 221, and the slots 221 on the upper and lower surfaces of the plug-in part 21 are provided in one-to-one correspondence; With solder paste. In addition, positioning portions 22 are provided at both ends of the PCB 20 along its extending direction. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com