Vehicle camera with focusing by employing screw rod

A camera and screw technology, applied in the field of vehicle cameras, can solve the problems of blurred images, easy generation of debris, high defect rate, etc., to achieve the effect of ensuring image quality and convenient adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

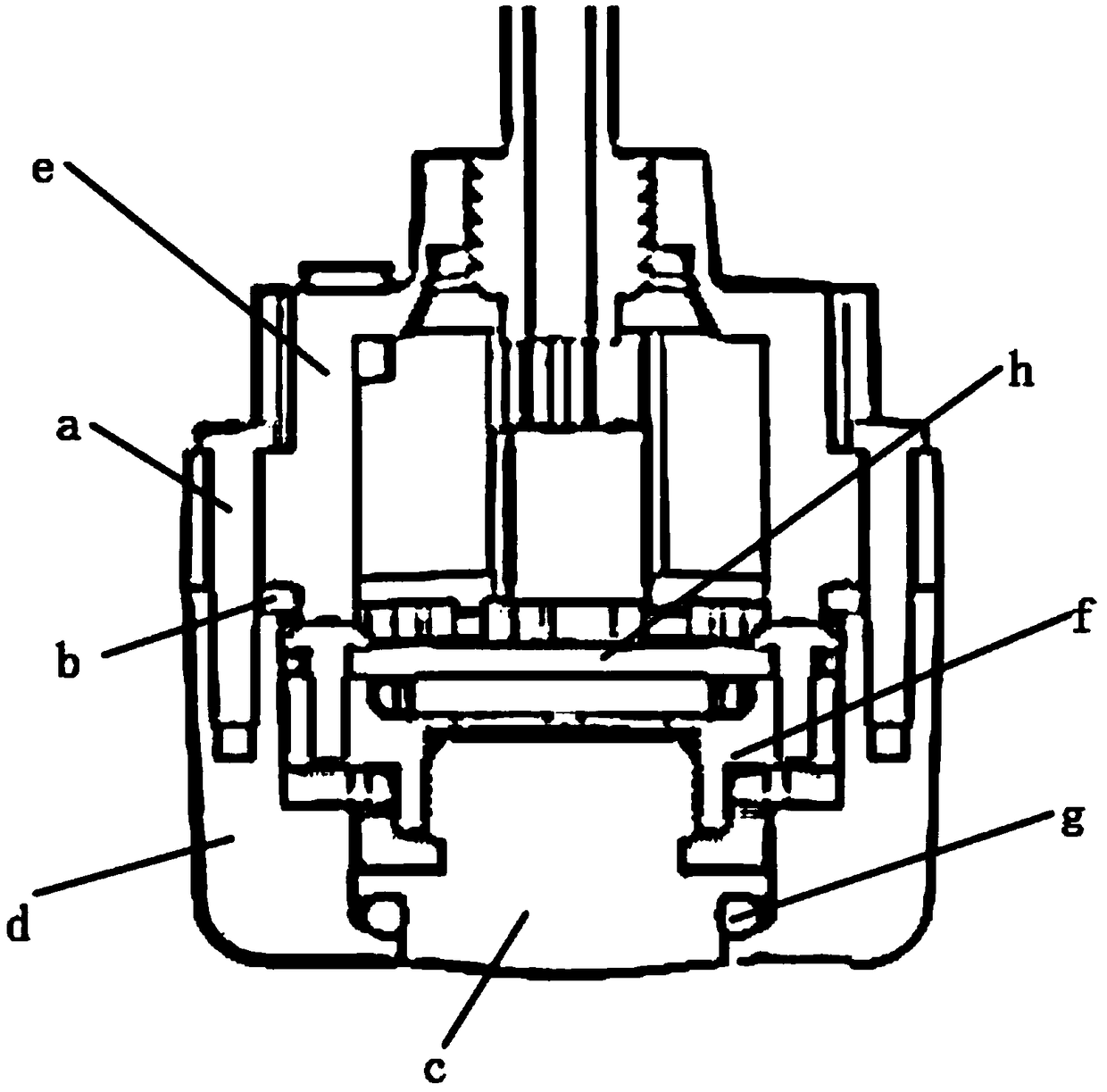

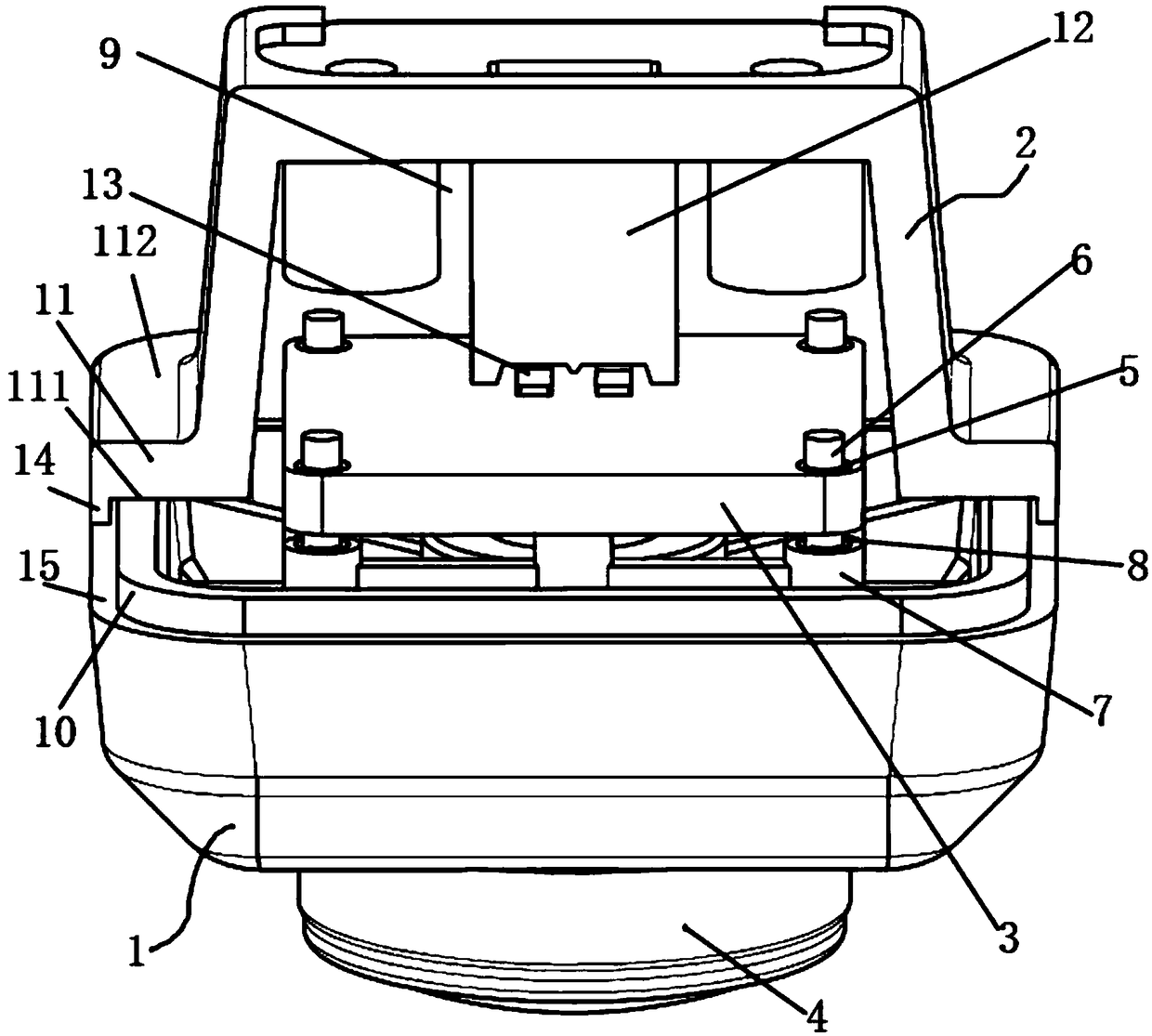

[0017] A screw focus vehicle camera, see figure 2 : it comprises a front shell 1, a rear shell 2, a sensor substrate 3, a camera lens 4, the front end of the front shell 1 is fixedly provided with a lordotic lens 4, and several thickness through holes are arranged around the sensor substrate 3, each A nut bushing 5 is fixedly installed in each of the through holes of the thickness, and each nut bushing 5 is threadedly connected with a corresponding screw rod 6, and the lower end of each said screw rod 6 is fixedly inserted into the corresponding installation position of the front shell. The inner ring of the bearing 7, the bearing 7 is fixedly installed in the installation hole of the corresponding installation position, and an adjustment distance 8 is left between the sensor substrate 3 and the bearing 7 at the corresponding installation position of the front shell 1, The sensor substrate 3 and the front shell 1 are connected by a screw 6 to form an integral structure, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com