Touch control display device

A technology of a touch display device and a heat sink, applied in the field of display screens, can solve the problems of cumbersome assembly process and complex structure, and achieve the effect of convenient assembly process and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

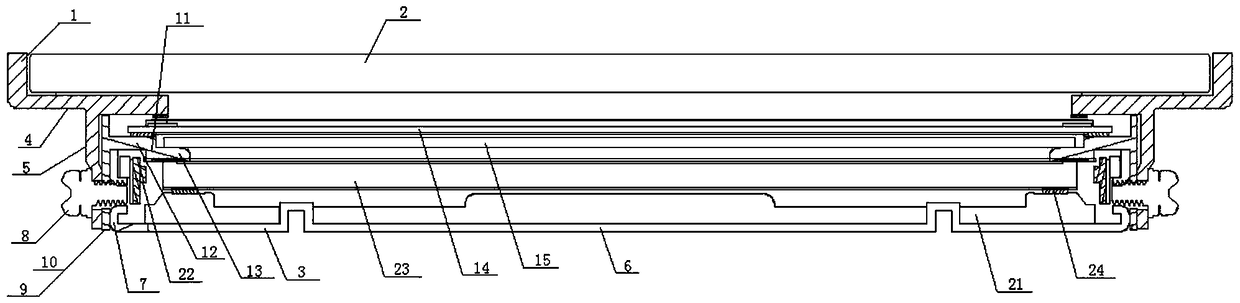

[0019] It can be known from the background technology that in the prior art, the capacitive touch panel and the face frame of the whole machine are independent from the liquid crystal module, and it is necessary to use a plurality of connecting brackets and screw connectors to perform the operation on the face frame and the back plate of the whole machine. Only by being fixed, the whole face frame and the liquid crystal module can be assembled together to form a capacitive liquid crystal display device. The structure of the entire capacitive liquid crystal display device is relatively complex, resulting in a cumbersome assembly process. In order to solve this problem, the present invention provides a touch display device.

[0020] The touch display device provided by the present invention will be described in detail below with reference to the accompanying drawings.

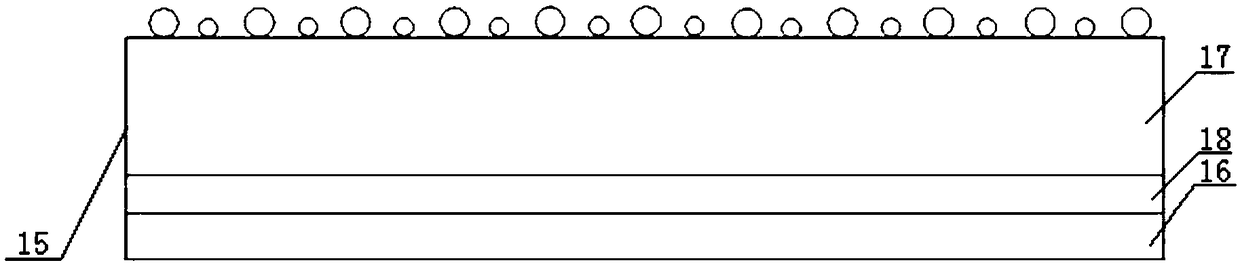

[0021] see figure 1 , figure 1 Shown is a schematic structural diagram of a touch display device provided by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com