Efficient flame retardant long-service-life optical cable

A long-life, fiber optic cable technology, applied in the direction of light guides, optics, optical components, etc., can solve the problems of poor fire and flame retardant effects and insect-proof effects of optical cables, and achieve the effects of improving fire-proof and flame-retardant effects, good insect-proof performance, and increasing life expectancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

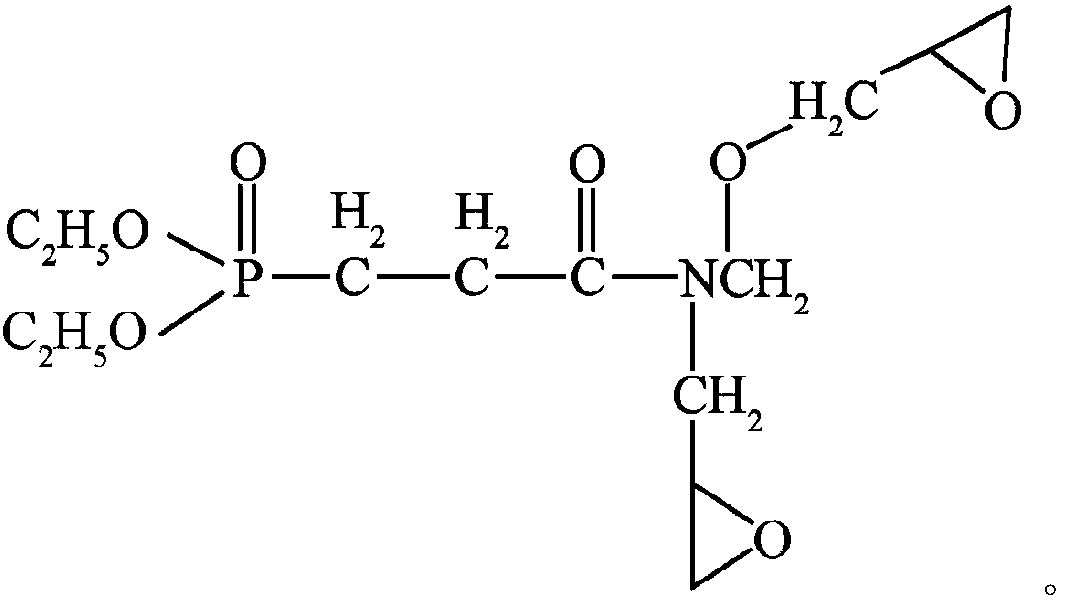

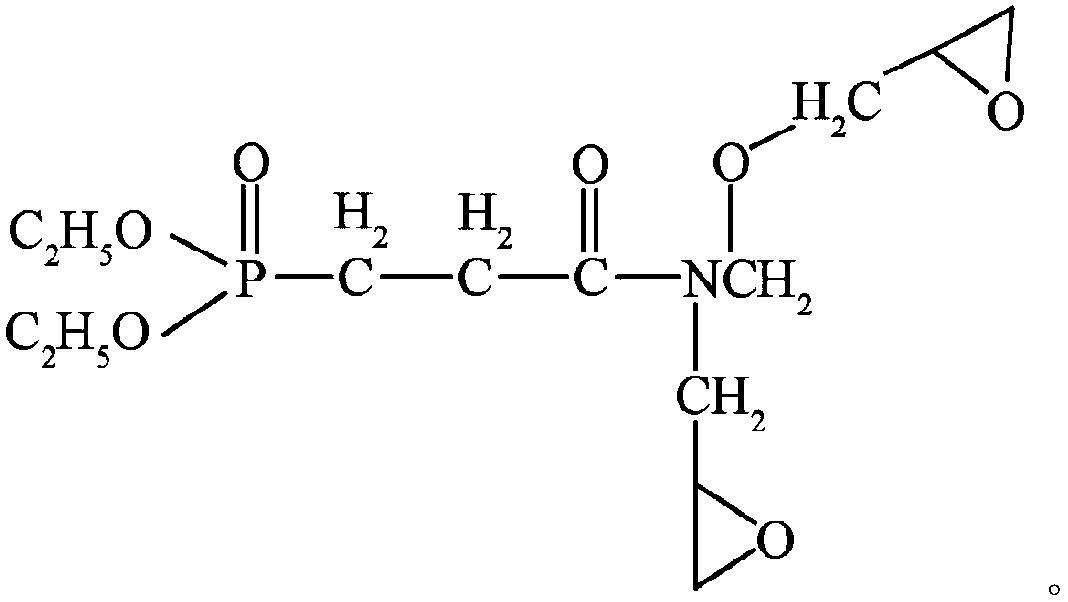

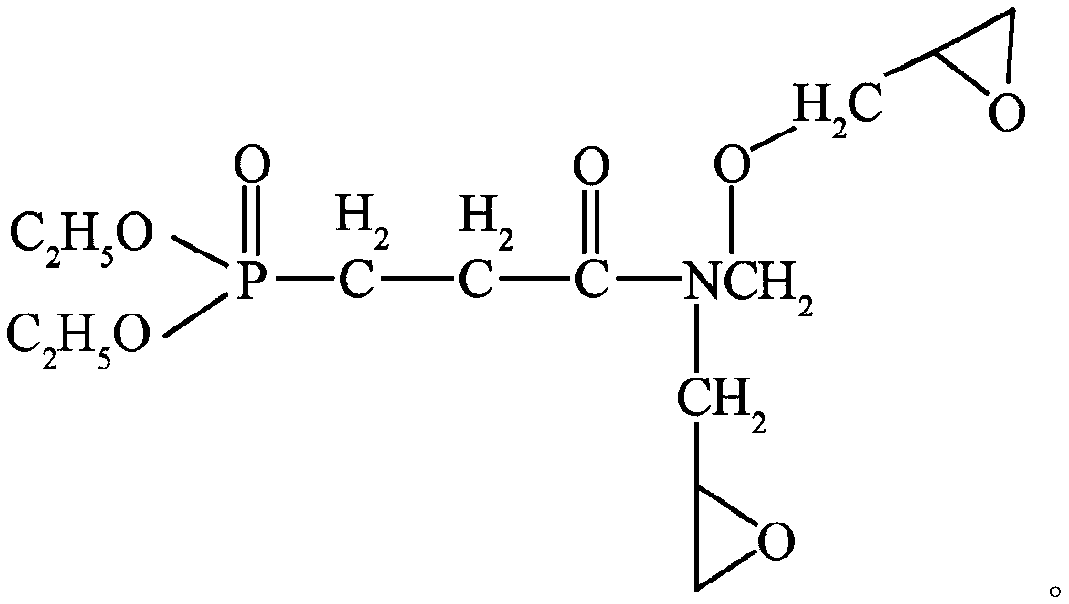

Method used

Image

Examples

Embodiment 1

[0022] A high-efficiency flame-retardant and long-life optical cable, which includes the outermost sheath, shielding layer, flame-retardant layer, innermost protective layer and cable core from the outside to the inside. The shielding layer is a compound of organosiloxane resin and AZO nanoparticles. The inner protective layer is a composite of polystyrene and silicon dioxide nanoparticles, and the cable core contains multiple optical fiber bundle tubes and a strengthening member located in the middle of the multiple optical fiber bundle tubes;

[0023] The outermost sheath is a mixture of polyvinyl chloride and an insect repellant, wherein the insect repellent is 3-[2-(3,5-dimethyl-2-oxocyclohexyl)-2-hydroxyethyl]pentanedi The mass ratio of imide, polyvinyl chloride and insect repellent in the outermost sheath is 10:1.

[0024] The average particle size of the AZO nanoparticles in the shielding layer is 40nm. The average particle diameter of the silica nanoparticles in the i...

Embodiment 2

[0028] A high-efficiency flame-retardant and long-life optical cable, which includes the outermost sheath, shielding layer, flame-retardant layer, innermost protective layer and cable core from the outside to the inside. The shielding layer is a compound of organosiloxane resin and AZO nanoparticles. The inner protective layer is a composite of polystyrene and silica nanoparticles, and the cable core contains multiple optical fiber bundle tubes and a strength member located in the middle of the multiple optical fiber bundle tubes.

[0029] The outermost sheath is a mixture of polyvinyl chloride and an insect repellant, wherein the insect repellent is 3-[2-(3,5-dimethyl-2-oxocyclohexyl)-2-hydroxyethyl]pentanedi The mass ratio of imide, polyvinyl chloride and insect repellant in the outermost sheath is 10:3.

[0030] The average particle size of the AZO nanoparticles in the shielding layer is 50nm. The average particle diameter of the silica nanoparticles in the innermost prote...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com