Level calibrator

A technology of horizontal calibrator and flat plate, which is applied in height/level measurement, instruments, measuring devices, etc., can solve the problems of inaccurate operation, difficult calibration, troublesome operation, etc., and achieve high calibration accuracy, convenient horizontal calibration, The effect of improving usability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The preferred embodiments of the present invention are given below in conjunction with the accompanying drawings to describe the technical solution of the present invention in detail.

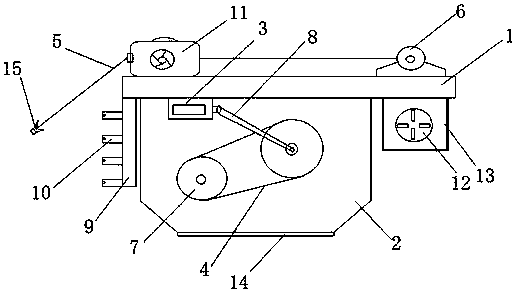

[0012] A horizontal calibrator, which includes a plane plate 1, a base 2, a motor 3, a synchronous belt 4, a rope 5, a bearing 6, a gear 7, a connecting shaft 8, an auxiliary column 9, a fixed head 10, a lock 11, a wire take-up The disc 12 and the storage frame 13, the plane plate 1 is installed above the base 2, the motor 3, the gear 7, the connecting shaft 8 and the timing belt 4 are installed in the base 2, the connecting shaft 8 is installed on the motor 3, and the connecting shaft 8 and a gear 7 are connected, there are two gears 7 and the two gears 7 are driven by a synchronous belt 4, and a bearing 6, a take-up reel 12, an auxiliary column 9, a fixed head 10 and a lock 11 are installed on the plane plate 1, The bearing 6 is located at the rear of the flat panel 1, and a storage fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com