A construction method for expansive soil subgrade with high groundwater level and low filling and shallow excavation

A construction method and soil roadbed technology, applied in roads, buildings, tracks, etc., can solve problems such as roadbed diseases, achieve the effects of stable roadbed structure, reduce construction difficulty, and save costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0028] In view of the Huanghuai Plain and Nanyang Basin high-level areas where the Zhengwangao Railway Line passes through, it is a high-water-table expansive soil foundation structure. In order to prevent the subgrade from being arched by the water-absorbing expansion force of the expansive soil, piles are poured under the subgrade filling layer in this embodiment. raft structure.

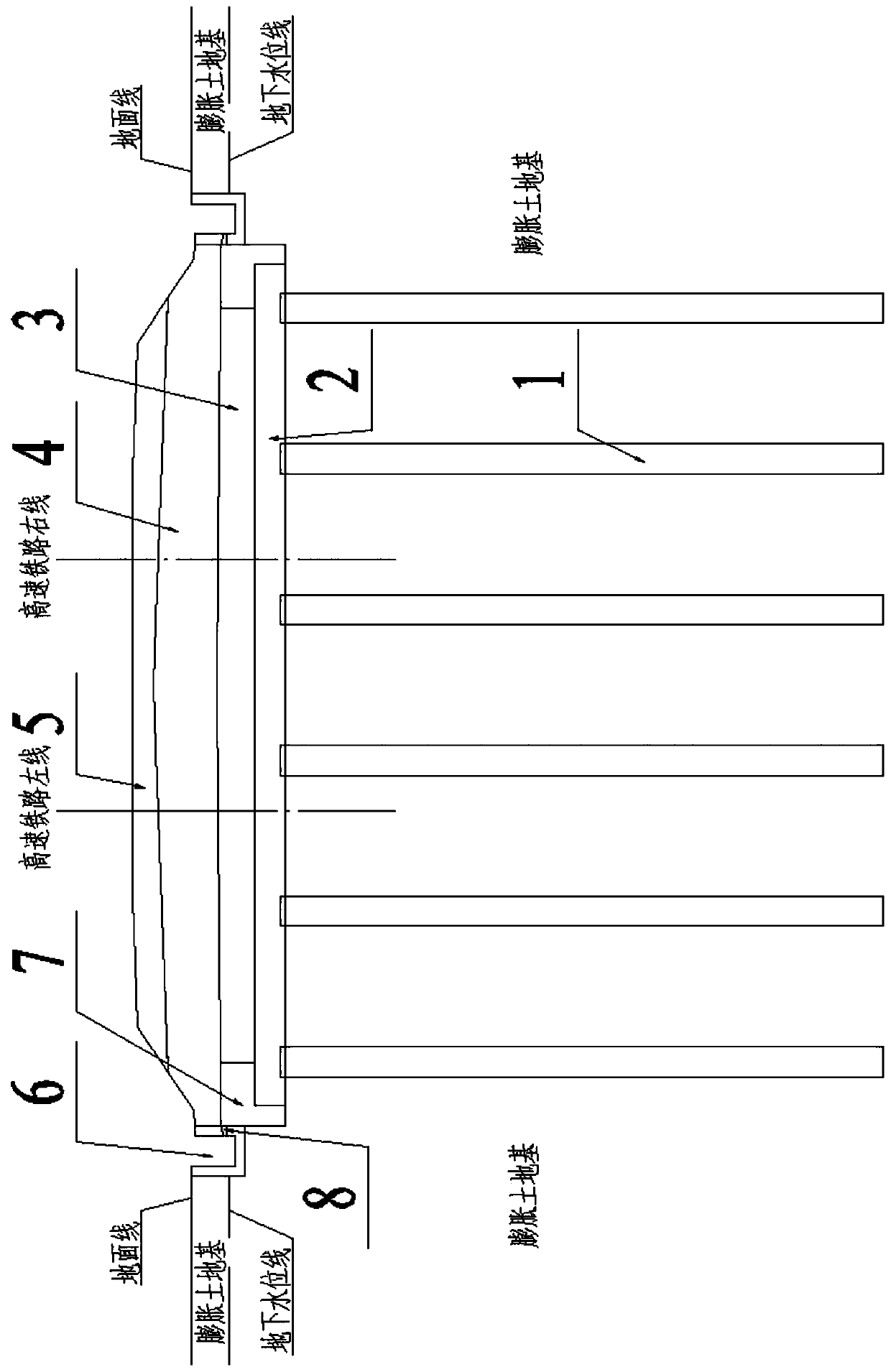

[0029] Such as figure 1 As shown, the pile raft structure of this embodiment includes a plurality of reinforced concrete piles 1 vertically supported below the roadbed filler layer and a reinforced concrete raft 2 fixed on the upper end of the reinforced concrete piles 1 . The reinforced concrete pile 1 is a bored cast-in-place pile with a pile diameter of 0.6-1.0m. The reinforced concrete raft 2 is located directly below the roadbed filler layer, and i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com