Yellow corn silage pretreatment method and device for straw biogas

A pretreatment device and straw technology, applied in the field of yellow storage devices, can solve the problems of cumbersome storage methods, inability to guarantee the nutrient group and water loss of the straw principle, and achieve the effect of retaining the loss of nutrient components and excellent fermentation raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

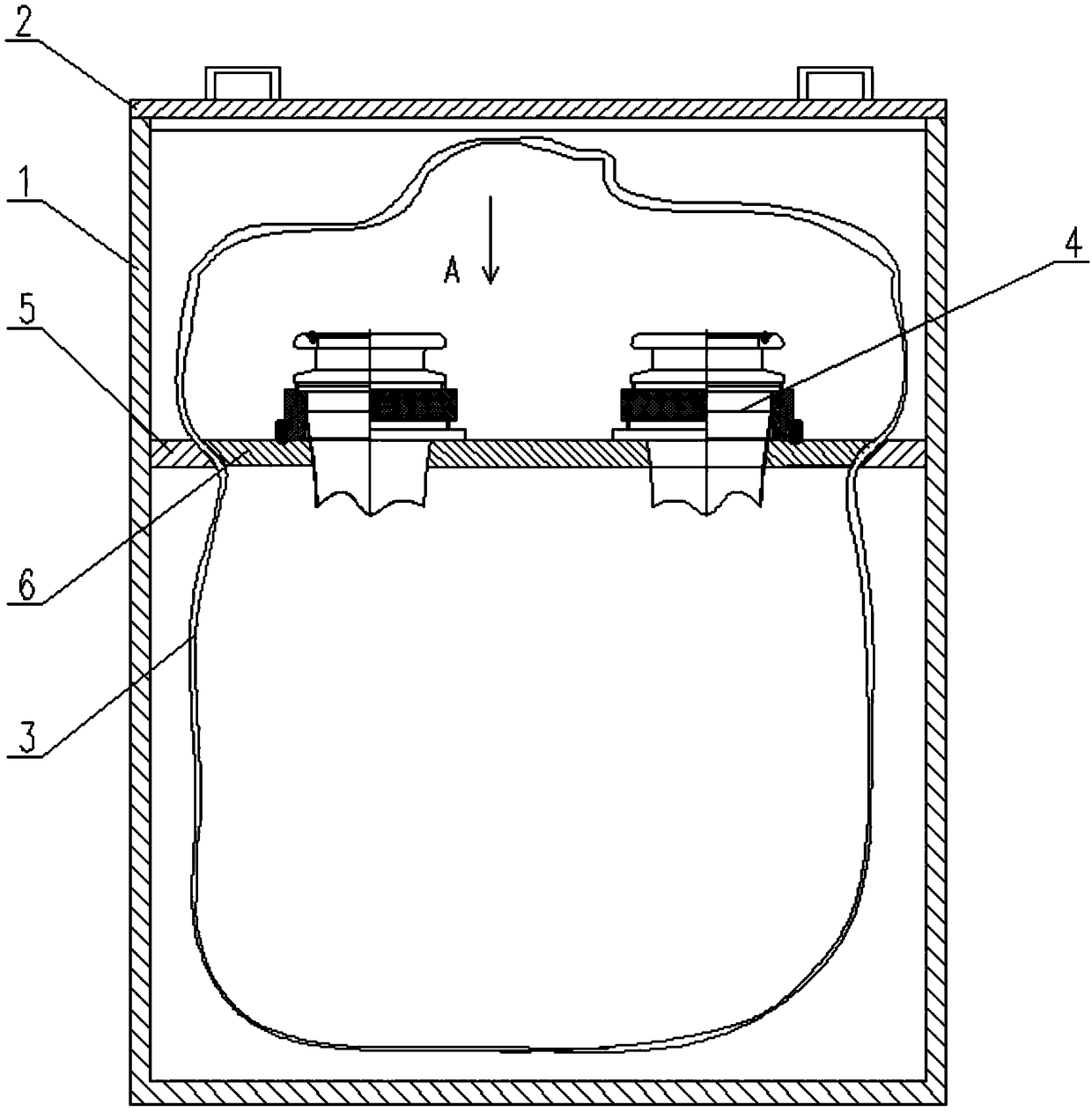

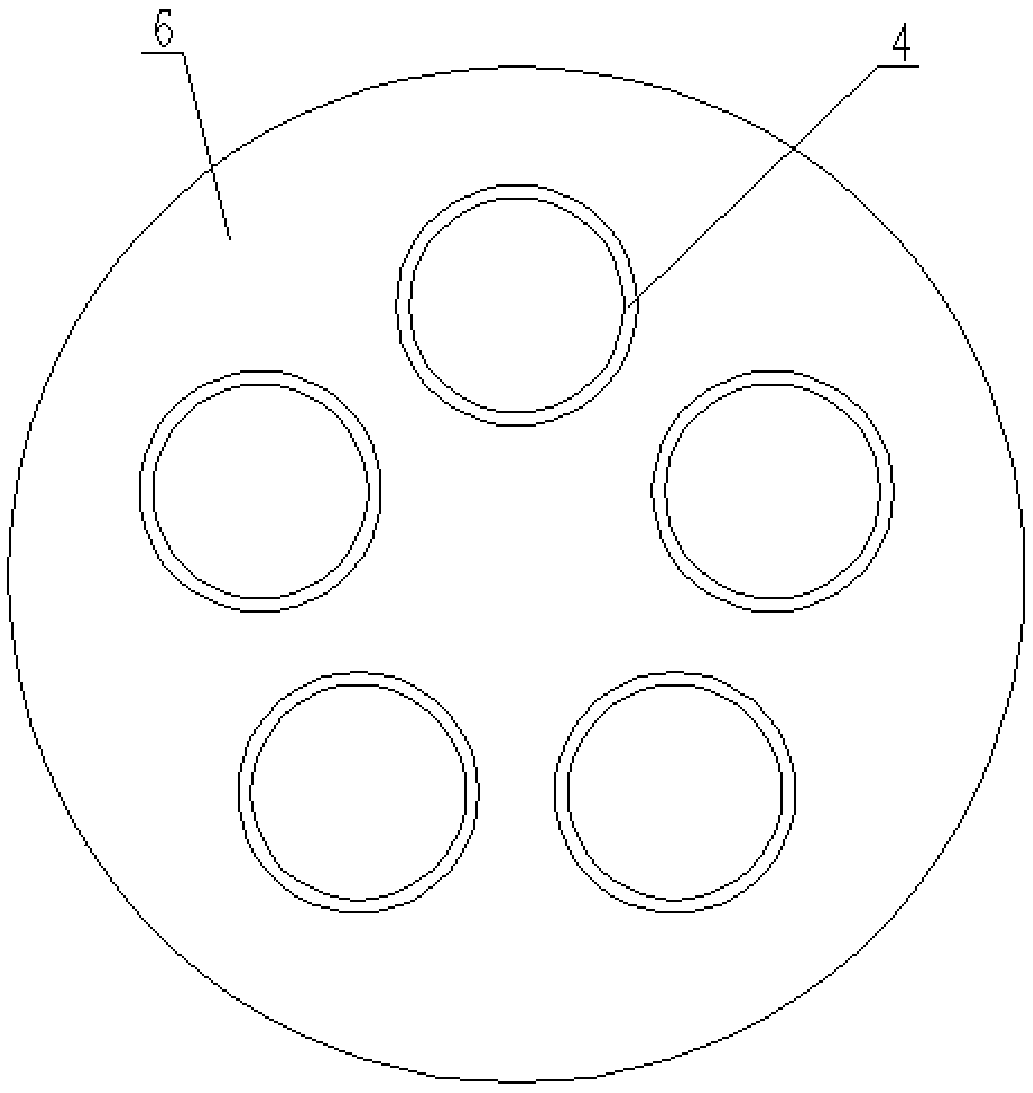

[0024] Specific implementation mode 1: Combination Figure 1-Figure 5 To explain this embodiment, a yellow storage pretreatment device for straw biogasification provided by this embodiment includes a yellow storage box body 1, a box cover 2, an outer yellow storage vacuum bag 3, and an inner yellow storage vacuum storage device 4 , The yellow storage box body 1 is a circular box body, the inner side wall of the yellow storage box body 1 is processed with a ring of annular clamping seat 5, the installation surface of the clamping seat 5 is an inclined installation surface, the yellow storage box The inside of the body 1 is provided with a mounting plate 6. The mounting plate 6 is a circular mounting plate, the outer side of the mounting plate 6 is an inclined mounting surface, the mounting plate 6 is clamped on the clamping seat 5, the mounting plate 6 and the clamping seat 5 The installation place is provided with an outer yellow vacuum storage bag 3, and the inner yellow vacuu...

specific Embodiment approach 2

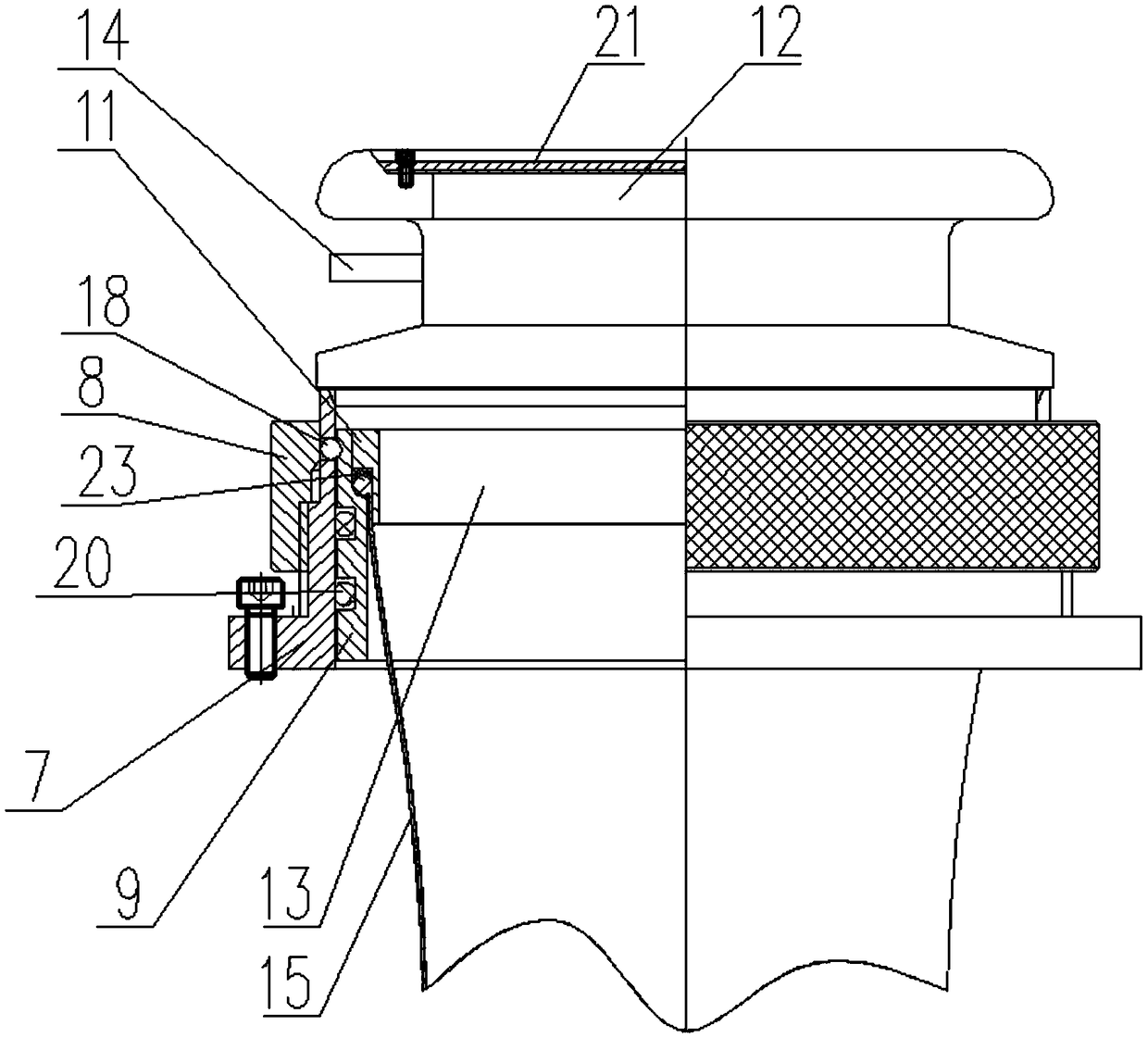

[0025] Specific implementation manner two: combination Figure 1-Figure 5 To explain this embodiment, this embodiment provides a yellow storage pretreatment device for straw biogasification. The inner yellow storage vacuum storage device 4 includes a fixed ring 7, a locking ring 8, a snap ring 9 and The mounting seat 10 and the inner yellow vacuum storage bag 15, the fixed ring 7 is an end flange type, the fixed ring 7 is fixedly installed on the mounting plate 6, the upper end of the mounting seat 10 has an installation inlet 12, the mounting seat A mounting through hole 13 is machined inside the mounting seat 10, and a vacuum tube 14 is also provided on the side wall of the mounting seat 10. The vacuum tube 14 communicates with the mounting through hole 13. The lower end of the mounting seat 10 has a connecting ring 11 through which the mounting seat 10 passes The connecting ring 11 at the lower end is inserted into the clamping ring 9, the curled edge of the inner yellow vac...

specific Embodiment approach 3

[0026] Specific implementation mode three: combination Figure 1-Figure 5 To illustrate this embodiment, this embodiment provides a yellow storage pretreatment device for straw biogasification. The outer side wall of the snap ring 9 is provided with a sliding groove 19, and the sliding groove 19 is installed Roll the slide 20. With this arrangement, the snap ring 9 can be smoothly inserted into the fixed ring 7 under the action of the rolling ball 20.

[0027] Specific implementation manner 4: Combination Figure 1-Figure 5 To illustrate this embodiment, this embodiment provides a yellow storage pretreatment device for straw biogasification. The upper end of the mounting seat 10 has an installation inlet 12 and a mounting cover 21 is buckled and covered. With this arrangement, there is a sealable gasket between the installation inlet 12 and the installation cover 21 to ensure that the installation seat 10 does not leak air.

[0028] Specific implementation manner five: combinati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com