Efficient anaerobic fermentation process using agricultural comprehensive waste as raw material

An anaerobic fermentation and waste technology, which is applied in the direction of waste fuel, fermentation, agriculture, etc., can solve the problems of destroying the balance of fermentation and the entry of low-temperature manure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

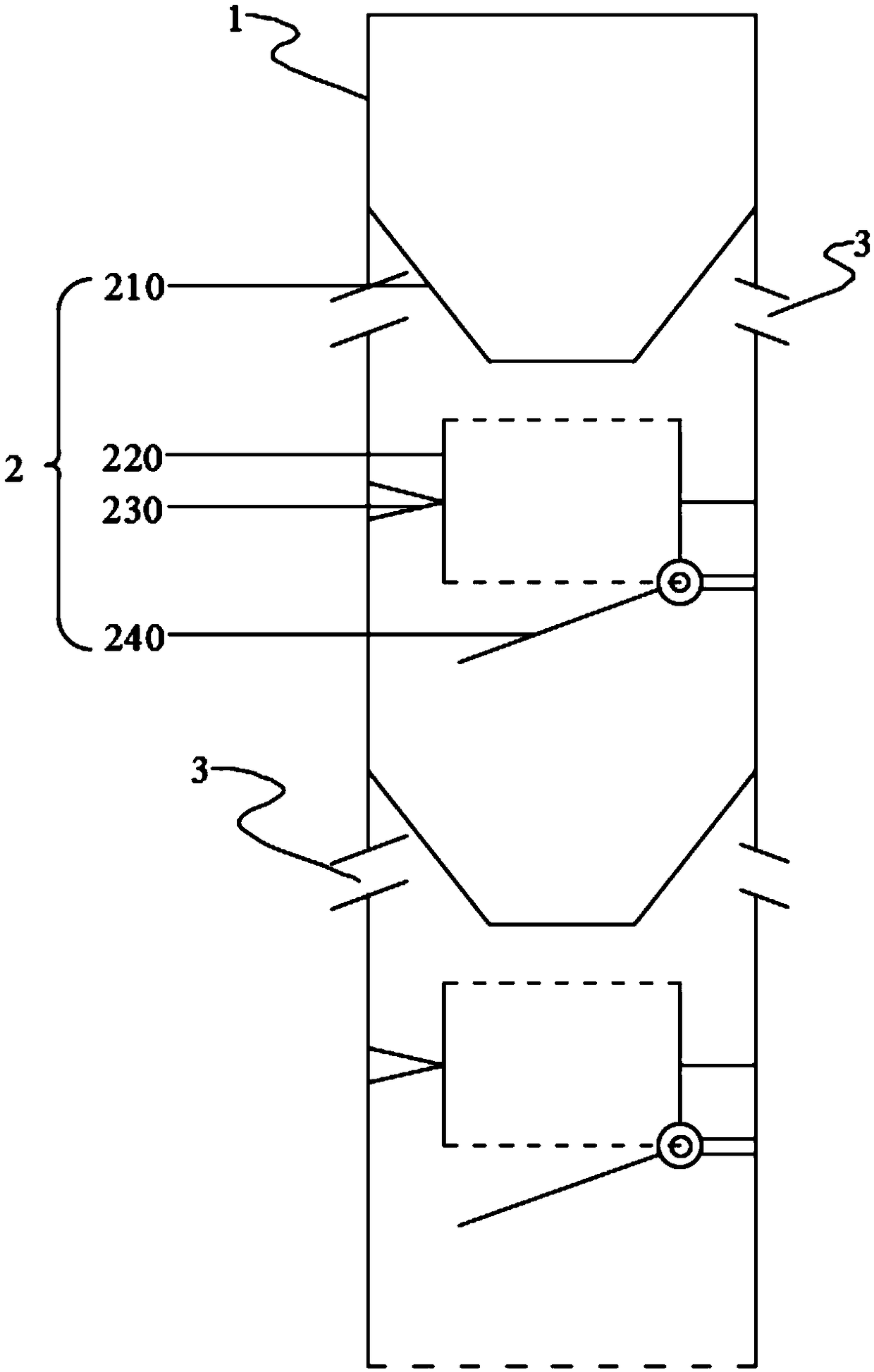

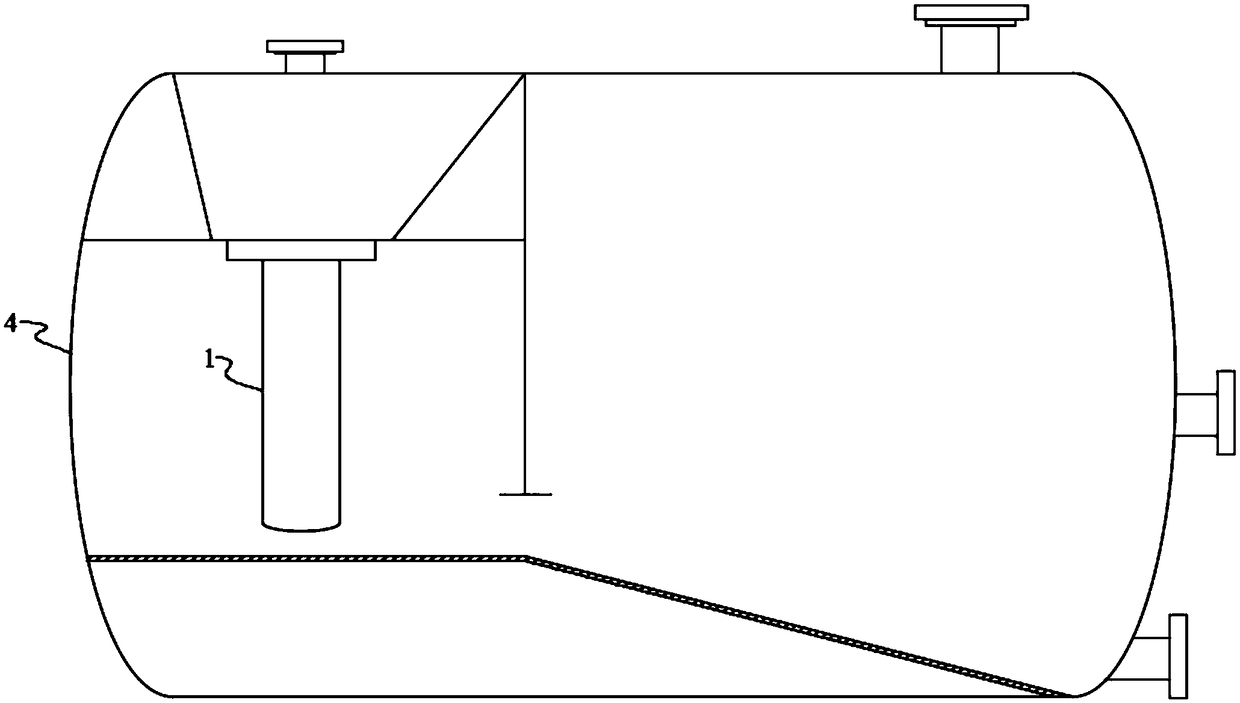

[0031] The high-efficiency anaerobic fermentation process using agricultural comprehensive waste as raw material of the present invention comprises the following steps:

[0032] S1 pretreatment: Send the agricultural comprehensive waste into the sewage collection tank. Before sending the agricultural comprehensive waste to the sewage collection tank, first let the agricultural comprehensive waste pass through the grid tank for natural sedimentation to remove the sediment in the feces, and at the same time Manual removal of suspended solids;

[0033] S2 Dilution Degradation: Return the biogas slurry to the agricultural comprehensive waste treated in the step S1. After a period of time, add clean water according to the amount of biogas slurry. Stir the agricultural comprehensive waste for 10 minutes to degrade part of the suspended matter;

[0034] S3 feed: the agricultural comprehensive waste treated in step S2 is transported to the fermentation tank through the feed pump for ...

Embodiment 2

[0041] The high-efficiency anaerobic fermentation process using agricultural comprehensive waste as raw material of the present invention comprises the following steps:

[0042] S1 pretreatment: Send the agricultural comprehensive waste into the sewage collection tank. Before sending the agricultural comprehensive waste to the sewage collection tank, first let the agricultural comprehensive waste pass through the grid tank for natural sedimentation to remove the sediment in the feces, and at the same time Manual removal of suspended solids;

[0043] S2 Dilution Degradation: Return the biogas slurry to the agricultural comprehensive waste treated in the step S1. After a period of time, add clean water according to the amount of biogas slurry. The agricultural comprehensive waste was stirred for 14 minutes to degrade part of the suspended matter;

[0044] S3 feed: the agricultural comprehensive waste treated in step S2 is transported to the fermentation tank through the feed pu...

Embodiment 3

[0051] The high-efficiency anaerobic fermentation process using agricultural comprehensive waste as raw material of the present invention comprises the following steps:

[0052] S1 pretreatment: Send the agricultural comprehensive waste into the sewage collection tank. Before sending the agricultural comprehensive waste to the sewage collection tank, first let the agricultural comprehensive waste pass through the grid tank for natural sedimentation to remove the sediment in the feces, and at the same time Manual removal of suspended solids;

[0053] S2 Dilution and Degradation: Return the biogas slurry to the agricultural comprehensive waste treated in the S1 step, and after a period of time, add clean water according to the amount of biogas slurry. The agricultural comprehensive waste was stirred for 18 minutes to degrade part of the suspended matter;

[0054] S3 feed: the agricultural comprehensive waste treated in step S2 is transported to the fermentation tank through the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com