Rolling pacing-improving load distribution method of reversible single-rack four-roller rough rolling mill

A technology of load distribution and rough rolling mill, applied in the direction of roll speed control, etc., can solve the problems of low rolling efficiency of rough rolling mill, and achieve the effects of shortening rough rolling rolling time, improving load utilization rate, good economic and social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1、 comparative example 1

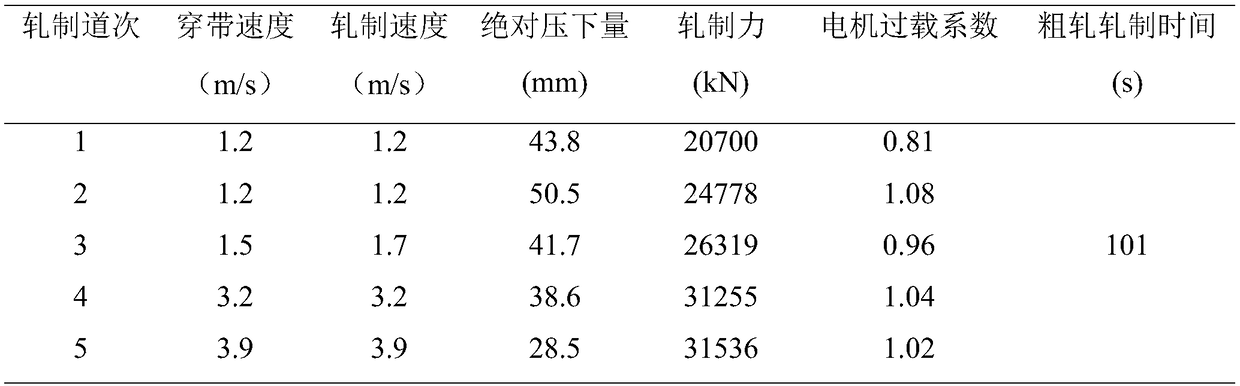

[0052] The steel type is marked as steel type A, the size of the incoming slab is 230mm×1300mm×9900mm, the size of the intermediate billet is 41.7mm×1260mm×59m, and the total number of rolling passes is 5.

[0053] In Comparative Example 1, the rough rolling time before implementation of the scheme was 101 seconds, and Table 1 is the rolling parameter table of Comparative Example 1.

[0054] In Example 1, the strip threading speed of the first 4 passes is increased to near the limit value, and the rolling speed of each pass is gradually increased to near the maximum value according to the equipment capacity and process requirements. Table 2 is the rolling parameter table after the implementation of the scheme , the rough rolling time has been reduced by 16 seconds.

Embodiment 2、 comparative example 2

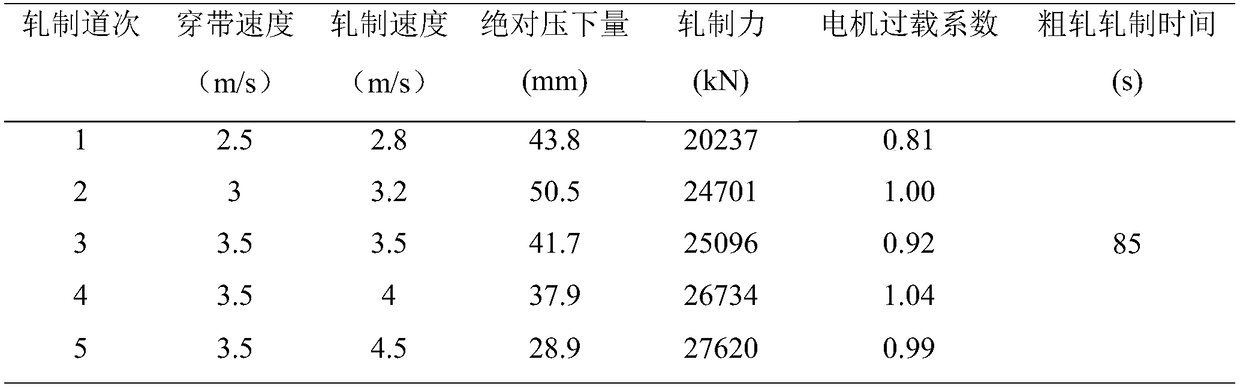

[0056] The steel type is marked as steel type B, the size of the incoming slab is 230mm×1300mm×9900mm, the size of the intermediate billet is 46mm×1270mm×53m, and the total number of rolling passes is 7.

[0057] In Comparative Example 2, the rough rolling time before the implementation of the scheme was 110 seconds, and Table 3 is the rolling parameter table of Comparative Example 2.

[0058] In Example 2, the strip threading speed of the first 3 passes is increased to near the limit value, and the rolling speed of each pass is gradually increased to near the maximum value according to the equipment capacity and process requirements. Table 4 is the rolling parameter table after the implementation of the scheme , the rough rolling time has been reduced by 14 seconds.

Embodiment 3、 comparative example 3

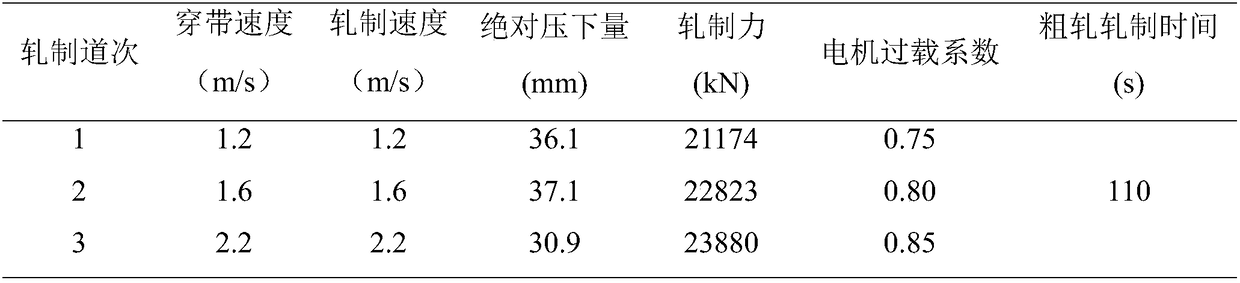

[0060] The steel grade is marked as steel grade C, the size of the incoming slab is 230mm×1300mm×9900mm, the size of the intermediate billet is 42mm×1276mm×56m, and the total number of rolling passes is 5.

[0061] In Comparative Example 3, the rough rolling time before the implementation of the scheme was 63 seconds, and Table 5 is the rolling parameter table of Comparative Example 3.

[0062] In Example 3, the strip threading speed of the first two passes is increased to near the limit value, and the rolling speed of each pass is gradually increased to near the maximum value according to the equipment capacity and process requirements. Table 6 is the rolling parameter table after the implementation of the scheme , the rough rolling time has been reduced by 7 seconds.

[0063] Table 1

[0064]

[0065] Table 2

[0066]

[0067] table 3

[0068]

[0069]

[0070] Table 4

[0071]

[0072] table 5

[0073]

[0074] Table 6

[0075]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com