A multi-robot collaborative sorting method and system

A multi-robot and robot technology, applied in the field of visual sorting, can solve the problems of affecting sorting efficiency, large missed catch rate, unreasonable sorting strategy, etc., and achieve the effect of improving sorting efficiency and improving position accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025]In order to further understand the content, characteristics, and efficacy of the present invention, it will be described in detail with reference to the accompanying drawings:

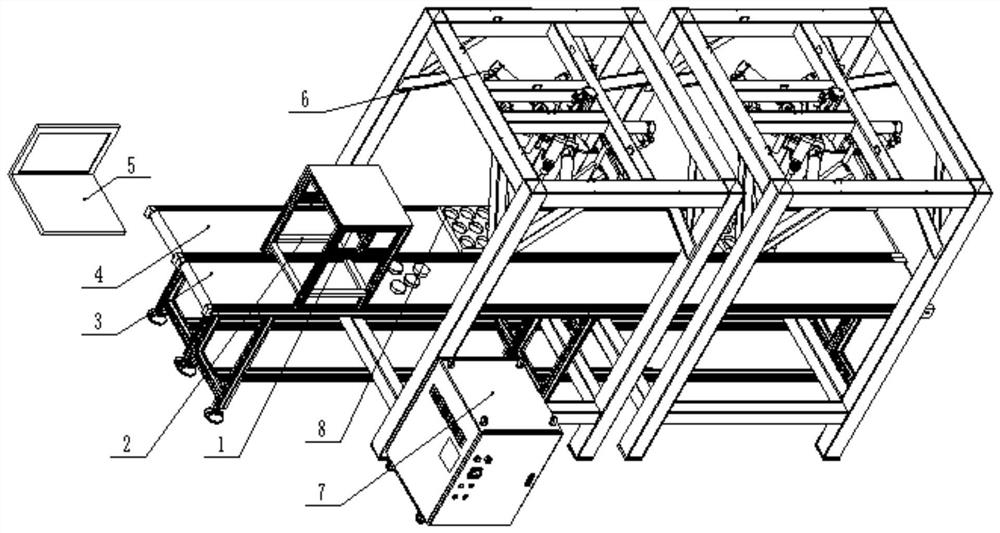

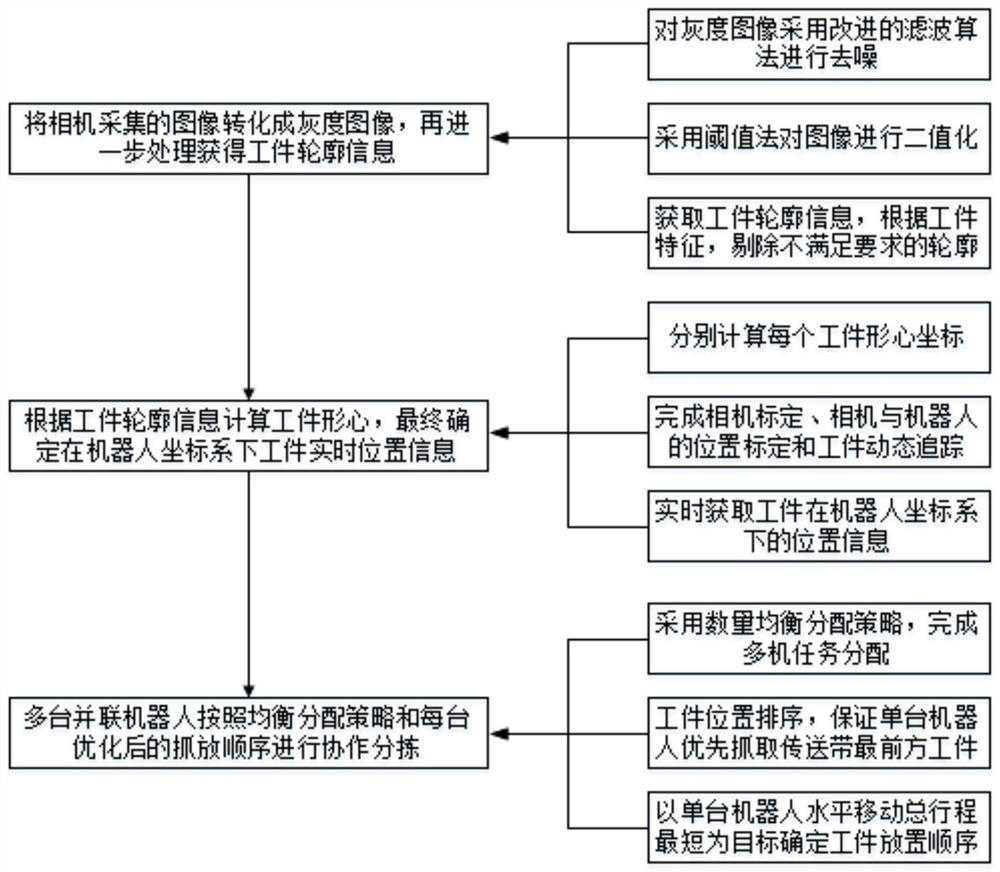

[0026]Seefigure 1 withfigure 2 A multi-robot cooperative sorting method, including the following steps:

[0027](1) Install the camera 1 on the transfer belt 3 and at the upstream of the parallel robot 6, the camera 1 is perpendicular to the conveyor belt 3, and the plurality of parallel robots are mounted downstream of the camera before and after the bracket. Above the conveyor belt 3 and the feed conveyor belt 4, the coder is mounted at the leftmost end of the transfer belt 3, and then activates the transfer belt 3 to convert the workpiece image collected by the camera 1 into a grayscale image through the hostile 5, and then further proceed Get workpiece profile information;

[0028]As a preferred embodiment, the workpiece image collected by the camera 1 is converted into a gradation image by the host compute...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com