Intelligent energy-saving automatic control method of dust removal system in thermal power plant

A technology of dust removal system and thermal power plant, applied in power supply technology, electrostatic separation and other directions, can solve the problem of the high electricity consumption rate of electrostatic precipitator and wet electrostatic precipitator, and the inability to automatically adjust operating parameters and operation methods at any time. High operating power consumption to achieve the effect of ultra-low emission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention is described in further detail below in conjunction with accompanying drawing:

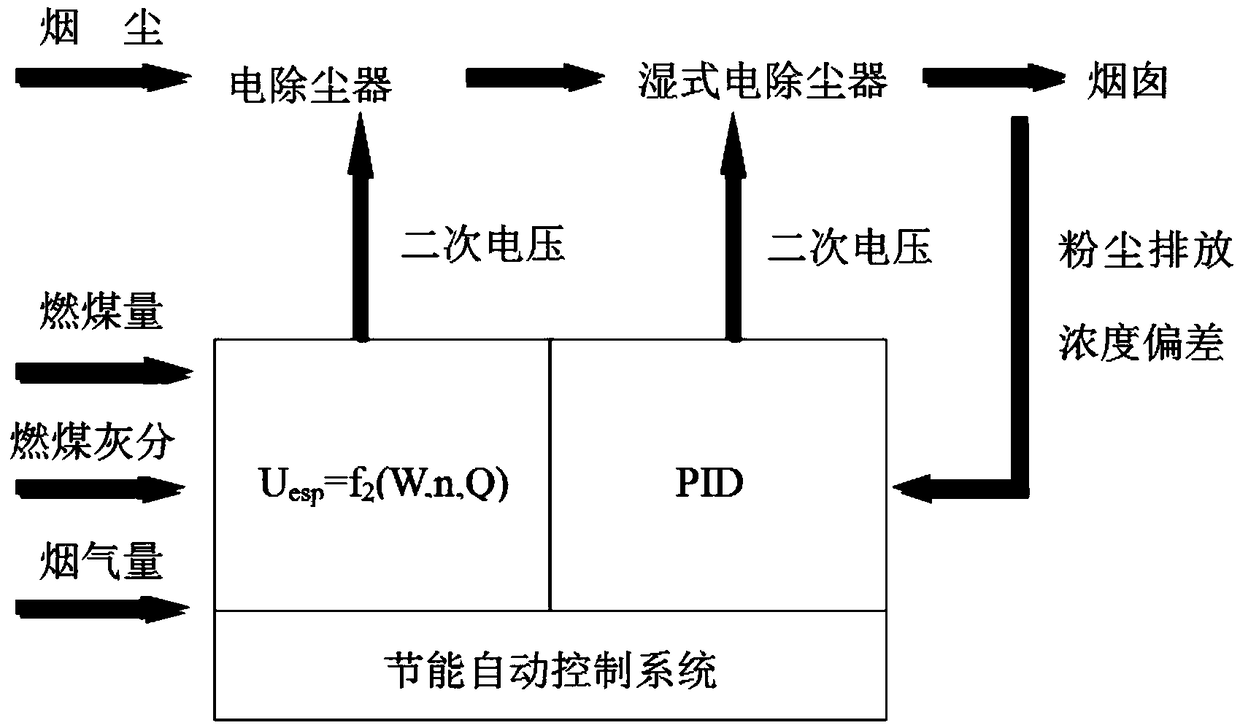

[0020] refer to figure 1 , the thermal power plant dust removal system intelligent energy-saving automatic control method comprises the following steps:

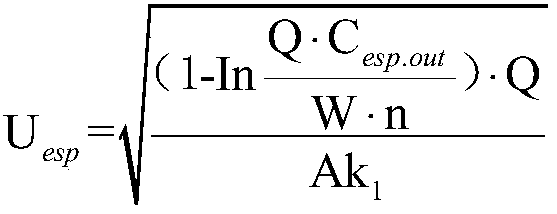

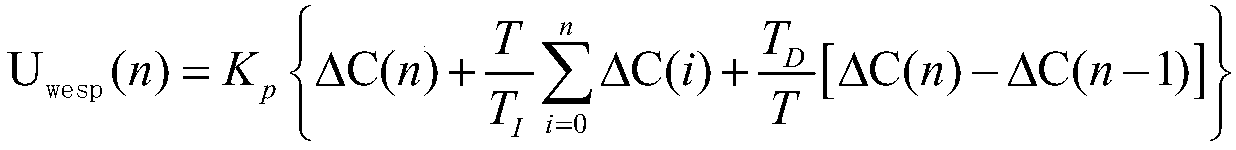

[0021] Real-time acquisition of unit coal consumption, coal combustion ash and flue gas volume, and then calculate the high-voltage power supply secondary voltage U of the electrostatic precipitator based on the unit coal combustion volume, coal combustion ash content and flue gas volume 电 The set value of U esp , and then according to the secondary voltage U of the high-voltage power supply of the electrostatic precipitator 电 The set value of U esp Adjust the secondary voltage U of the high-voltage power supply of the electrostatic precipitator through the DCS system 电 , where, the secondary voltage U of the high voltage power supply of the electrostatic precipitator 电 The set value of U esp The expression is:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com