Online ultrasonic detection apparatus and detection method for reactor coolant pump flange bolt

A flange bolt, ultrasonic testing technology, applied in the direction of measuring devices, using sound waves/ultrasonic waves/infrasonic waves to analyze solids, using sound waves/ultrasonic waves/infrasonic waves for material analysis, etc., can solve problems such as insufficient travel, limited space for flange bolts, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0068] The present invention will be further described below in conjunction with accompanying drawing.

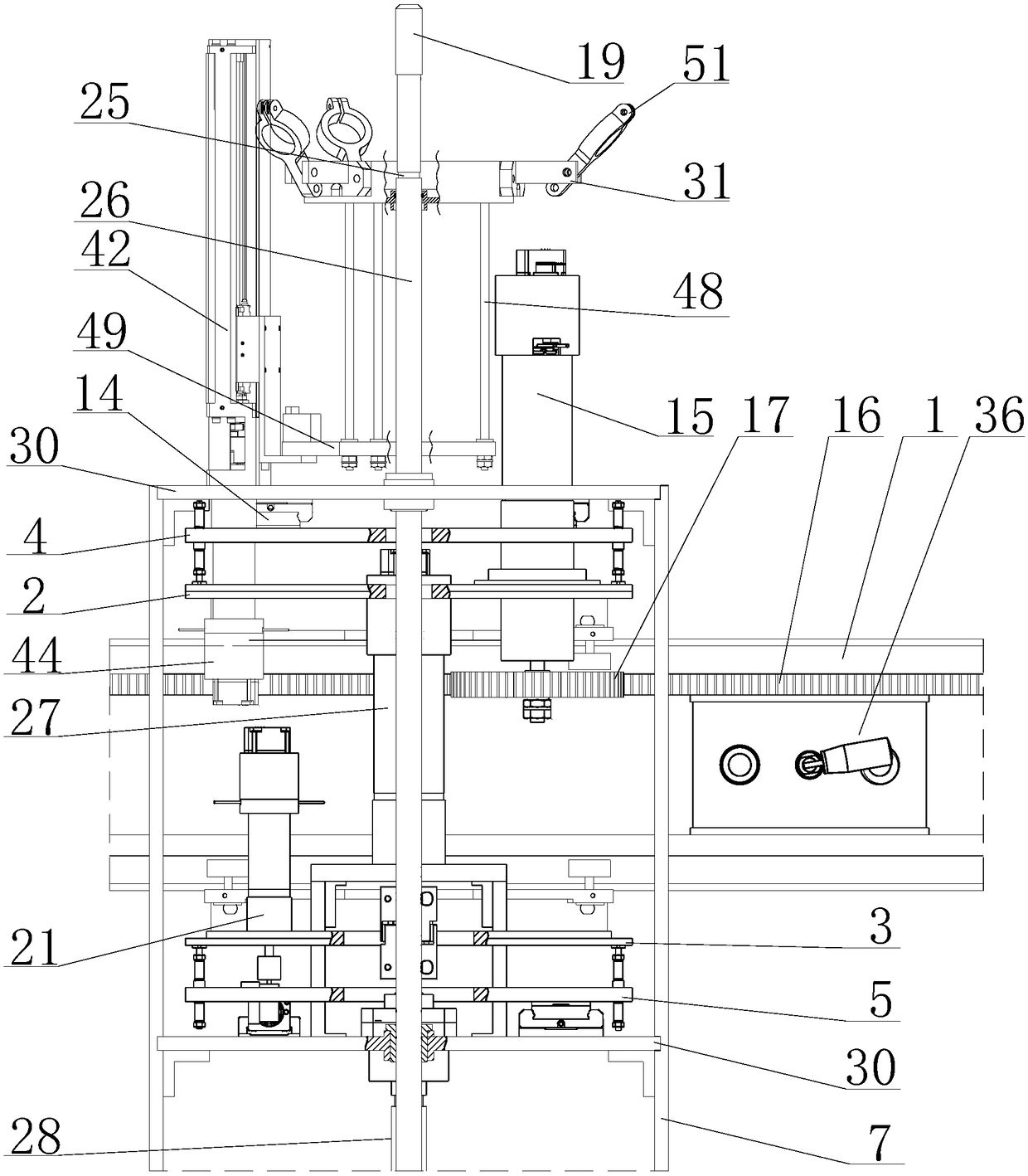

[0069] The on-line ultrasonic testing device for flange bolts of the nuclear main pump is mainly composed of three modules: guide rail 1, sliding seat and testing platform 7.

[0070] Such as Figure 12 , Figure 13 As shown, the guide rail 1 is divided into three sections, and each section consists of two sections of arc-shaped half guide rails fixed together through the mounting seat 37 of the flexible clamping assembly 36. In this embodiment, the mounting seat 37 is U-shaped with the opening facing outward. The positioning plate, the upper and lower ends are fixed in the middle of the upper and lower arc-shaped semi-rails; the upper arc-shaped semi-rail is provided with an arc-shaped rack that cooperates with the driving gear 17, and the arc-shaped racks of the three-section guide rail 1 are spliced into a circle The complete ring gear 16; the quick connection betwee...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com