Variable stroke valve train for internal combustion engines

A valve train, internal combustion engine technology, used in internal combustion piston engines, combustion engines, machines/engines, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

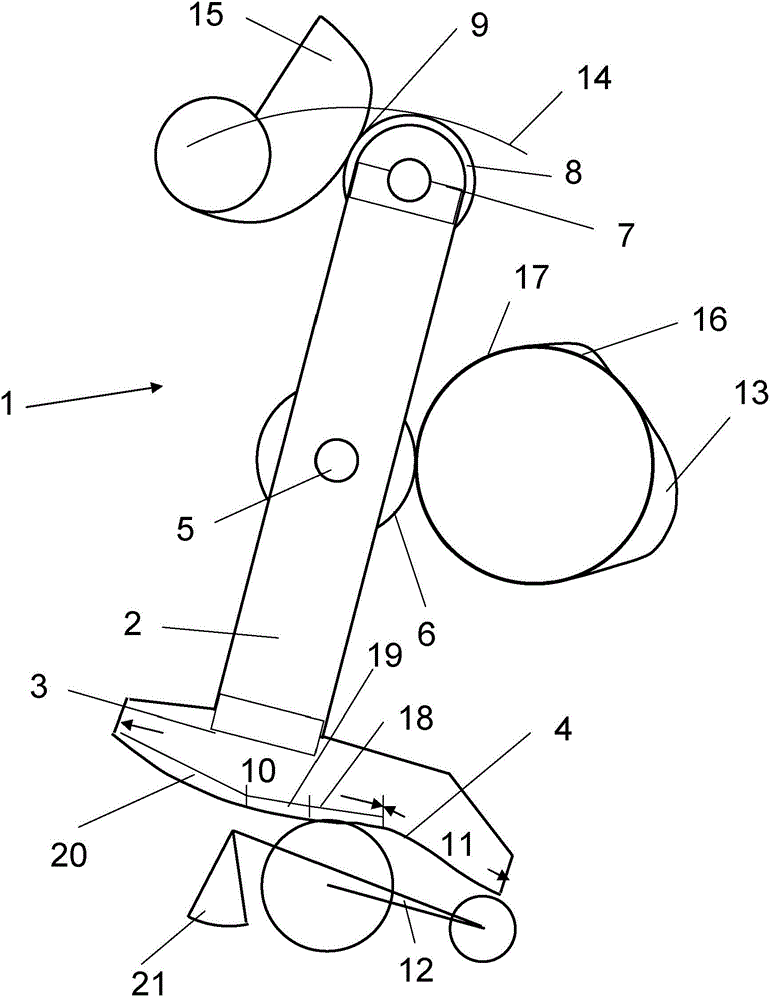

[0013] figure 1 The full variable valve mechanism 1 of the internal combustion engine is shown. From the basic structure and function, it is equivalent to the BMW electronic valve control system.

[0014] The valve mechanism 1 is composed of a long rocker 2. The long rocker 2 has an integrally coupled transmission surface 4 on the lower end 3, and the transmission surface 4 is composed of a zero-stroke track 10 and a stroke track 11 following the zero-stroke track along the pivoting direction of the lever, and the transmission The face 4 is in contact with a valve opener 12, which exists as a rocker arm and rests on a support element not shown in the area shown on the right here.

[0015] Observed from the stroke track 11, the aforementioned zero stroke track 10 successively has a switch-on zero-stroke section 18, a cut-off zero-stroke section 19 and a remaining zero-stroke section 20, wherein, according to figure 1 The zero-stroke segment 18 is turned on to contact the valve opene...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com