Folding sheet covering machine

A technology of folding board and cover machine, applied in packaging and other directions, can solve the problems of low efficiency and high labor cost of enterprises

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

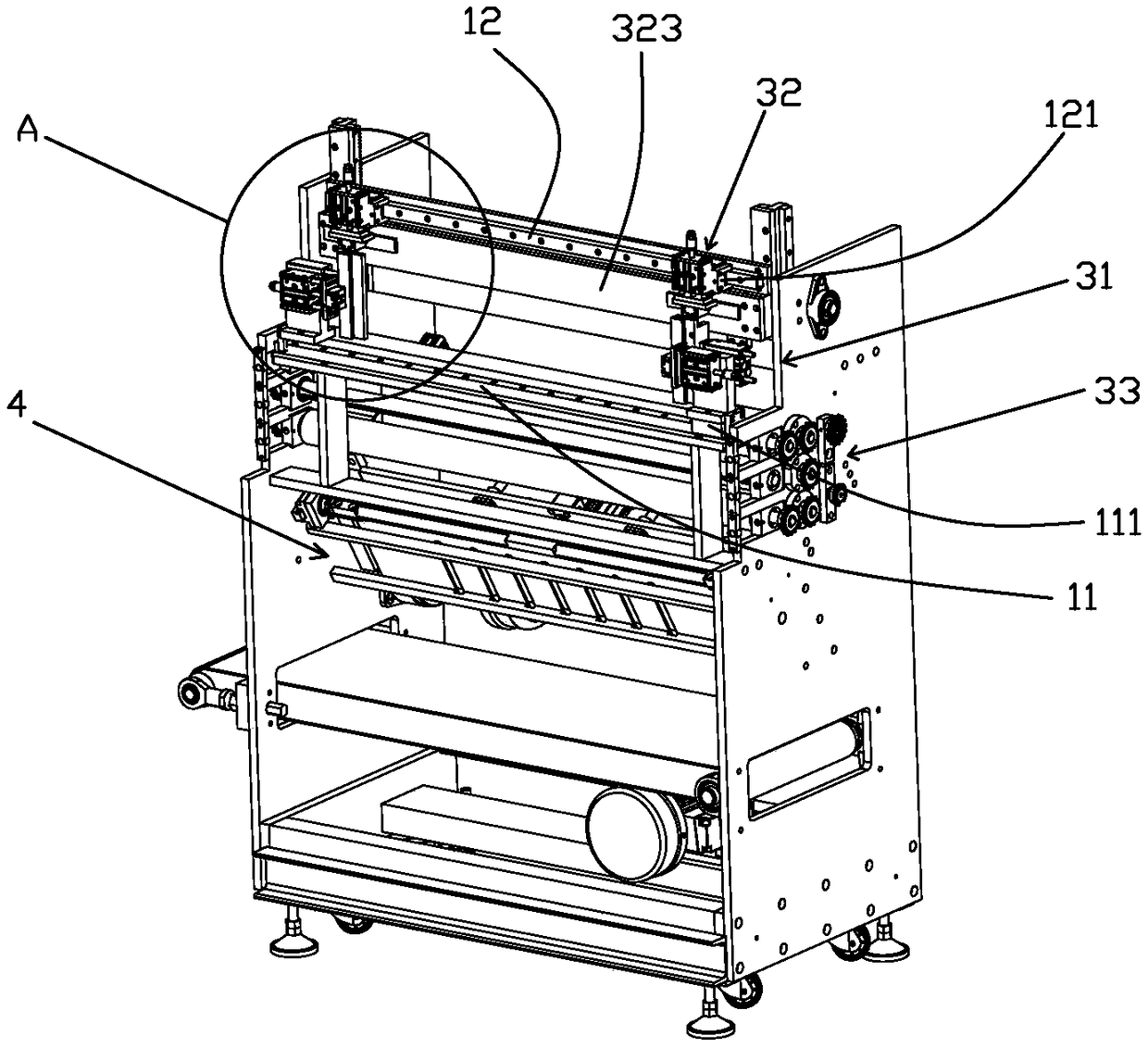

[0035] Specific embodiments of the present invention such as Figure 1-10 As shown, the up-down direction referred to in the present invention refers to the up-down direction relative to the ground when the folding board cover machine is placed on the ground in a working state.

[0036] A folding board cover machine includes a frame 1 on which a feeding device 2 , a cover device 3 and a discharging device 4 are arranged.

[0037]The feeding device 2 includes a feeding conveyor belt 21, a gripping mechanism 22 for grabbing a folded board, and a driving mechanism 23 for driving the gripping mechanism 22 to reciprocate and slide toward the cover device 3. The feeding conveyor belt 21 The input end 21a and the output end 21b correspond to the two ends of the frame 1, and the grabbing mechanism 22 has a first position state and a second position state corresponding to the side edge hemming and the upper edge hemming of the folded plate respectively.

[0038] The cover device 3 inc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com