Hybrid drive system with AMT transmission

A hybrid power and drive system technology, which is applied to the layout of multiple different prime movers of hybrid vehicles, power plants, and general power plants, and can solve problems that affect vehicle driving safety, engine or motor failure to drive, power interruption, etc. problems, to achieve the effect of improving acceleration performance and climbing speed, simple layout structure, ensuring comfort and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in combination with specific embodiments.

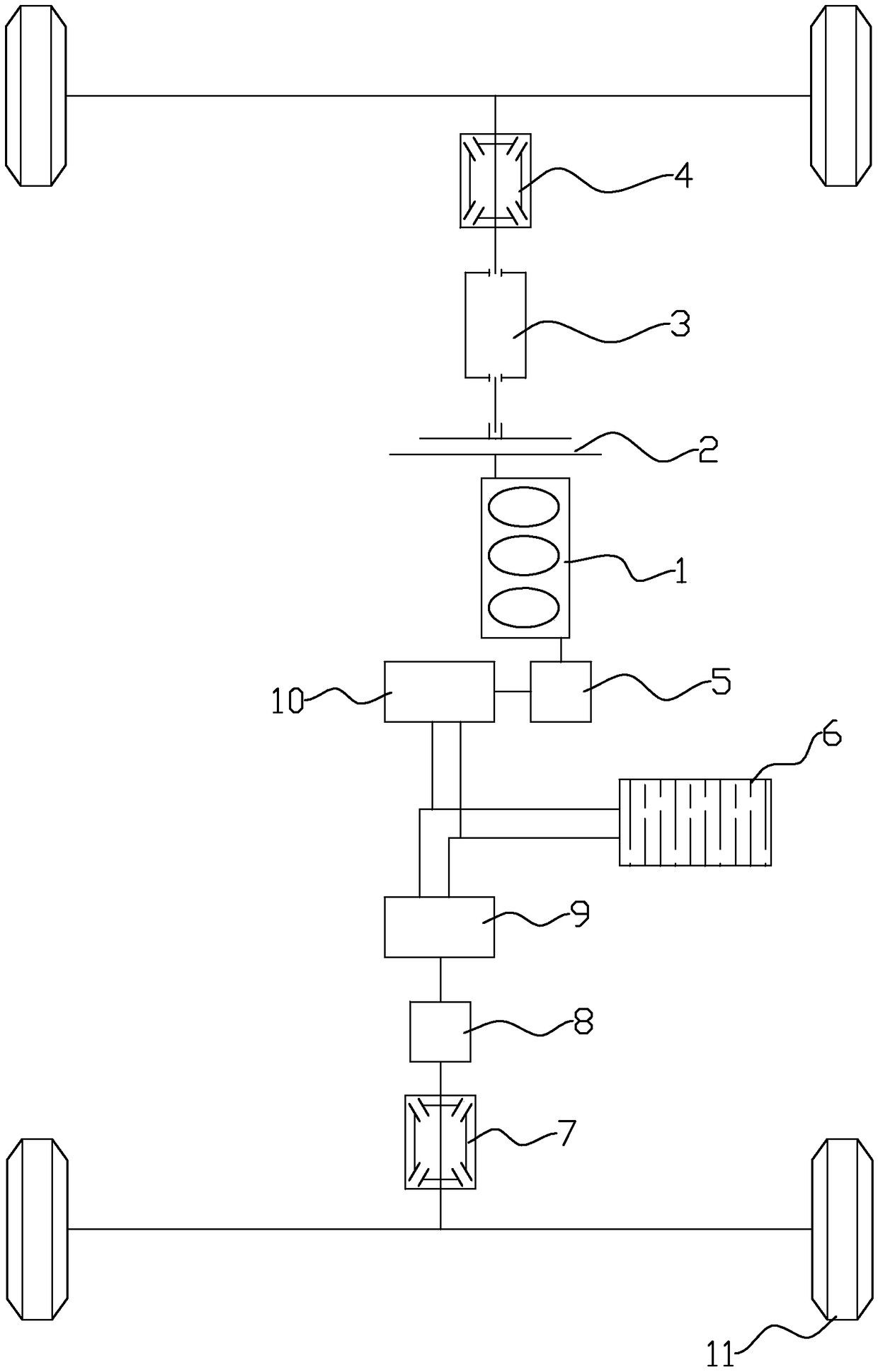

[0015] The invention provides a hybrid drive system with an AMT transmission, figure 1 It is a schematic diagram of the structure of the present invention combined with a vehicle, including a first drive part, a second drive part and a control part; the first drive part is connected to the second drive part, and both the first drive part and the second drive part are connected to a power battery 6. The power source of the first drive part is electric power and fuel-powered hybrid power, and the power source of the second drive part is pure electric power; the control part controls the second drive part to run alone or the first drive part and the second drive part Cooperate with each other to run at the same time, and monitor the power of the power battery 6 and control charging and discharging.

[0016] The second driving part can always keep running, or it can only run w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com