Cold-chain production technology for pork

A production process, pork technology, applied in food freezing, meat/fish preservation, heating preservation of meat/fish, etc., can solve the problem of pork deterioration, achieve the effect of reducing bacterial content, improving taste, and good effect of acid discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

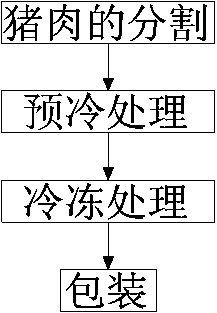

[0020] A kind of pork cold chain production technique, described production technique comprises the steps:

[0021] (1) Segmentation of pork: Segment the pigs after slaughter, so that the pork is divided into: meat products, bone products, by-products and refined products according to the processing parts. The temperature of the segmentation workshop is controlled between 12 and 15°C , the tools for pork segmentation need to be cleaned and sterilized three times a day;

[0022] (2) Pre-cooling treatment. After the pork is cut and processed, the cooling workshop is pulled down, and the temperature is gradually lowered and cooled through three different temperatures of 10°C, 5°C and 0°C. Finally, the central temperature of the pork product is not higher than 7°C. The cooling time of the temperature stage is controlled at 1h, 1.6h and 14h respectively. During the pre-cooling process of pork products, ultraviolet germicidal lamps are used for auxiliary sterilization, and the ultra...

Embodiment 2

[0033] A kind of pork cold chain production technique, described production technique comprises the steps:

[0034] (1) Segmentation of pork: Segment the pigs after slaughter, so that the pork is divided into: meat products, bone products, by-products and refined products according to the processing parts. The temperature of the segmentation workshop is controlled between 12 and 15°C , the tools for pork segmentation need to be cleaned and sterilized three times a day;

[0035] (2) Pre-cooling treatment. After the pork is cut and processed, the cooling workshop is pulled down, and the temperature is gradually lowered and cooled through three different temperatures of 15°C, 10°C and 4°C. Finally, the center temperature of the pork product is not higher than 7°C. The cooling time of the temperature stage is controlled at 1.6h, 2.2h and 16h respectively. During the pre-cooling process of pork products, ultraviolet germicidal lamps are used for auxiliary sterilization, and the ult...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com