Combined tension-torsion multi-axis fracture experimental system and experimental method

The technology of an experimental system and experimental method is applied in the field of tensile-torsion combined multi-axial fracture experimental system, which can solve the problem of lack of experimental data support and verification of the damage model, and achieve the effect of realizing full-field strain and measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

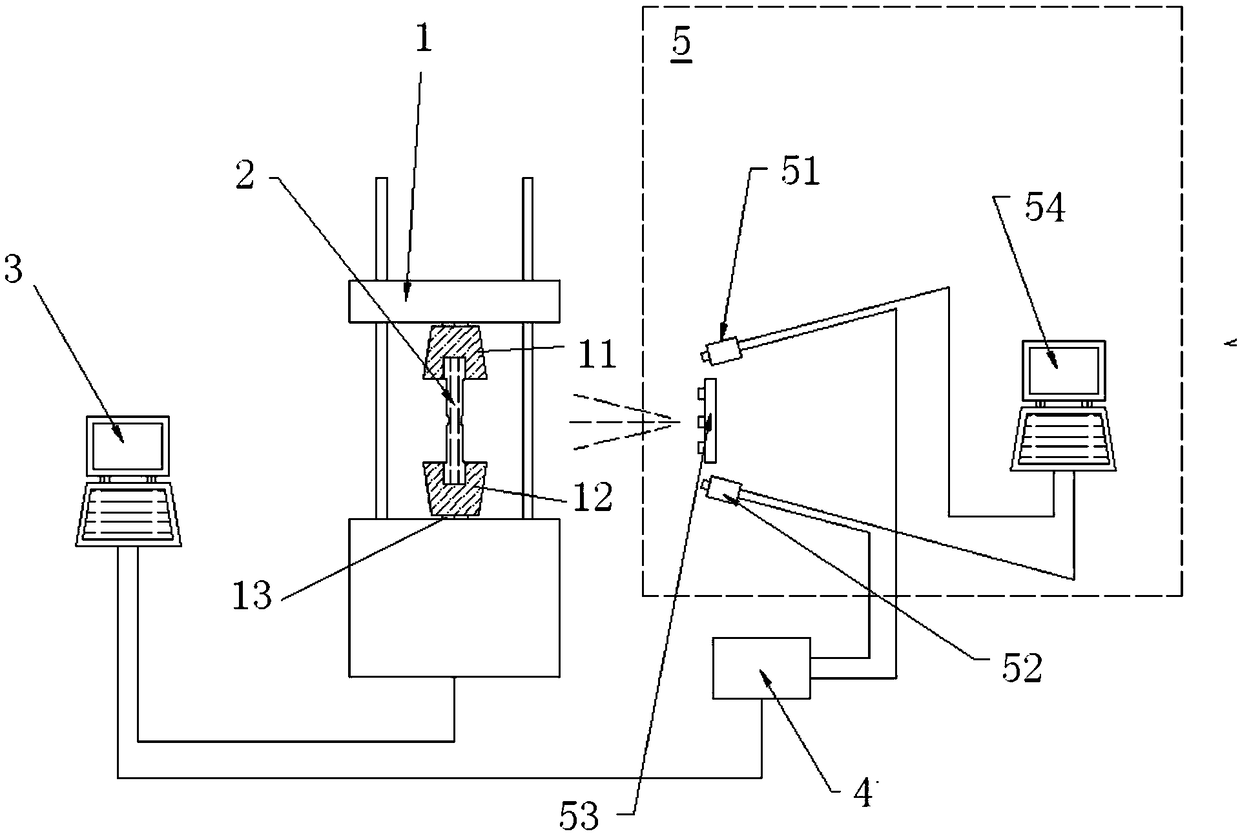

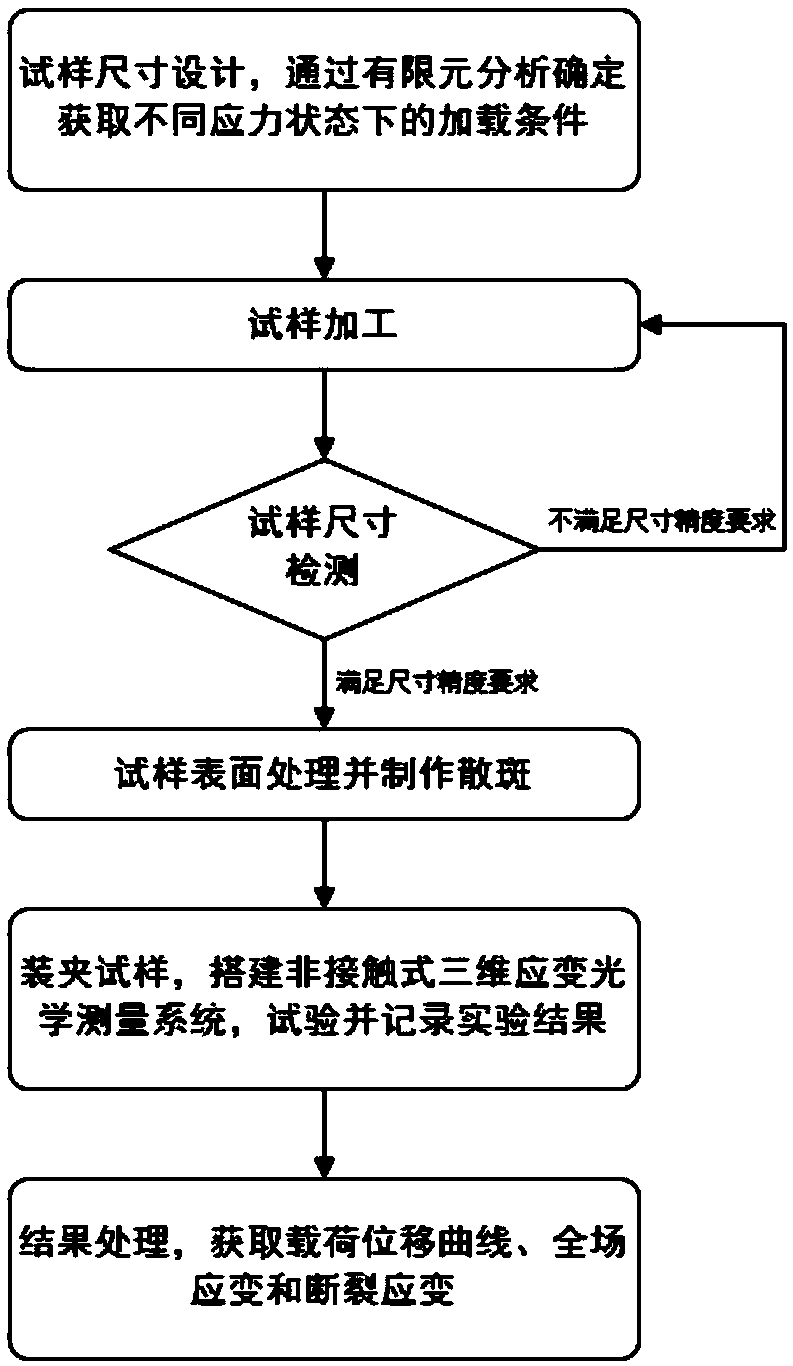

[0028] Such as figure 1 Shown is the tensile-torsion combined multiaxial fracture test system according to an embodiment of the present invention, which includes the dynamic tensile-torque testing machine 1 of the 809 model of MTS Company, a non-contact three-dimensional strain optical measurement system 5, a control device 3 and A synchronous trigger device 4 .

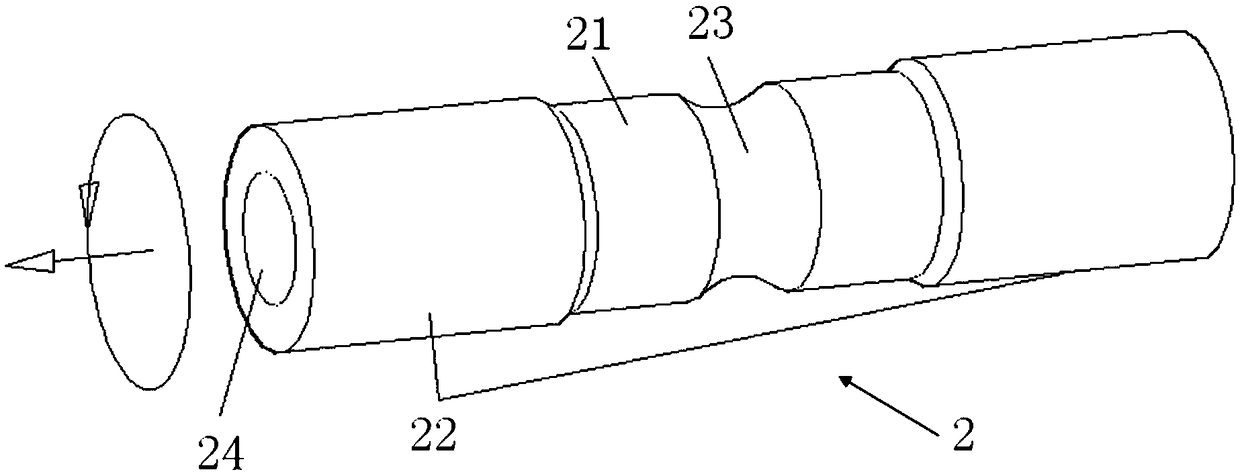

[0029] The dynamic tension testing machine 1 has an upper chuck 11, a lower chuck 12 and a force sensor 13, and a sample 2 is clamped in the dynamic tension testing machine by the upper chuck 11 and the lower chuck 12 respectively. 1, the force sensor 13 measures axial tension and torque (ie load). The non-contact three-dimensional strain optical measurement system 5 can adopt the non-contact three-dimensional strain optical measurement system of Correlated Solutions, including two cameras 51, 52 connected with the synchronous trigger device 4 and two cameras 51, 52 An image acquisition and data processing device 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com