Real-time detection device and method for width of lamination line of silicon steel sheets

A real-time detection, silicon steel sheet technology, applied in the field of transformer manufacturing, can solve the problems of lamination errors and low reliability, and achieve the effect of rapid detection, high reliability, accurate automatic lamination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

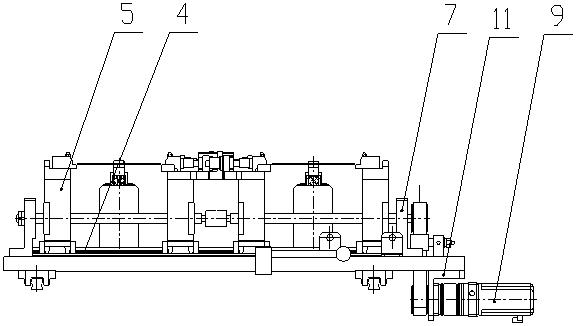

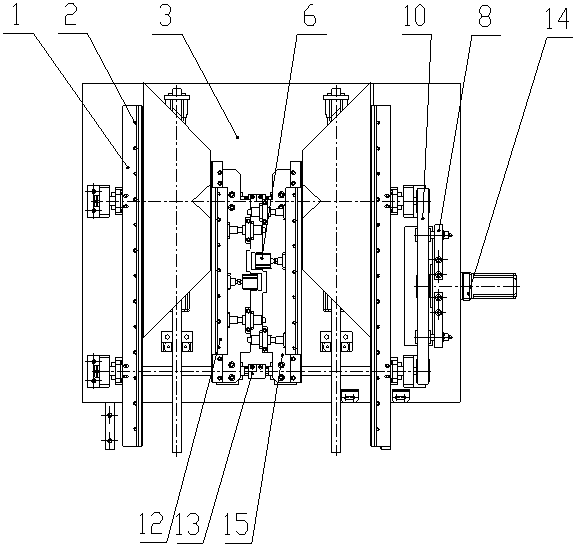

[0031] In order to overcome the problems of lamination errors and low reliability caused by the width deviation of silicon steel sheets during the operation of the existing automatic lamination machine, the present invention provides such Figure 1-4 The device and method for real-time detection of the width of a silicon steel sheet stacking line has a simple structure and high reliability, and can realize zero-error lamination production of transformer cores. The optical fiber detection device provided in the present invention has high precision and sensitivity, and performs on-line detection on the silicon steel sheet before lamination to ensure that it is completely consistent with the designed sheet material of the transformer core. The setting of the optical fiber detection device ensures that the detection of each silicon steel sheet is foolproof during the lamination process.

[0032] A silicon steel sheet stacking line width real-time detection device, including five s...

Embodiment 2

[0036] Based on the above embodiments, in this embodiment, the two sets of yoke post guide rails are arranged on the bottom plate 15 through the yoke post screw socket 5 , and the yoke post guide rails include a yoke post left guide rail 1 and a yoke post right guide rail 12 .

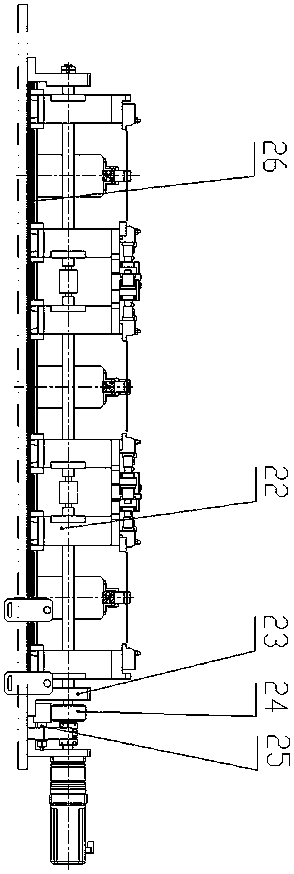

[0037] like figure 1 and 2 As shown, the real-time detection device for the width of the yoke column includes a support 7, a yoke column tensioner 8, a yoke column width adjustment servo motor 9, a yoke column synchronous pulley 10, a yoke column servo support plate 11, and a yoke column transmission structure , the yoke column width-adjusting guide rail reducer 14 and the platen 3, the yoke column width-adjusting servo motor 9 is connected to the bottom surface of the platen 3 through the yoke column servo support plate 11, and the lower end of the yoke column synchronous pulley 10 and the yoke column width-adjusting The guide rail reducer 14 is connected, the yoke column width adjustment guide rail ...

Embodiment 3

[0049] Based on the basis of embodiments 1 and 2, a method for real-time detection of the width of a silicon steel sheet stacking line is provided in this embodiment, and the specific steps are:

[0050] Step 1. When stacking the transformer core automatic lamination machine, firstly, the silicon steel sheet is placed on the slicing guide rail in the slicing device through the previous slicing process, and the lamination grabbing manipulator grabs the silicon steel sheet at the slicing guide rail and Placed in the yoke column width adjustment guide rail, side column width adjustment guide rail and center column width adjustment guide rail, and then the cylinder 6 pneumatically controls the clamping yoke column width adjustment guide rail, side column width adjustment guide rail and center column width adjustment guide rail, and makes the current The edge of the width sheet silicon steel sheet is tangent to the sliding assembly 2 provided in each set of width-adjusting guide rai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com