Foundation pit pumping device

A technology for pumping devices and foundation pits, which is applied in pump devices, components of pumping devices for elastic fluids, infrastructure engineering, etc., can solve problems such as pump damage, pumping pipeline damage, and shortening the service life of the pump , to achieve the effect of convenient use, energy saving and speeding up the flow rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

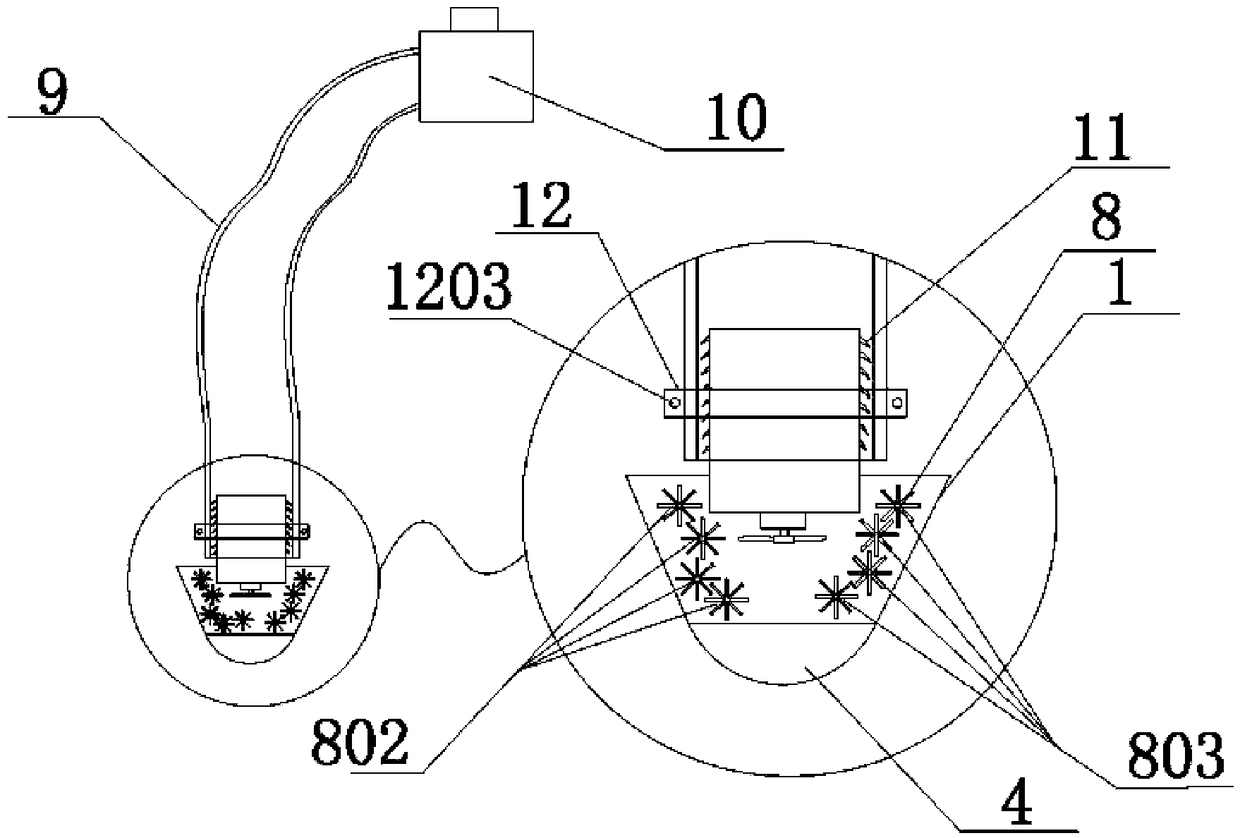

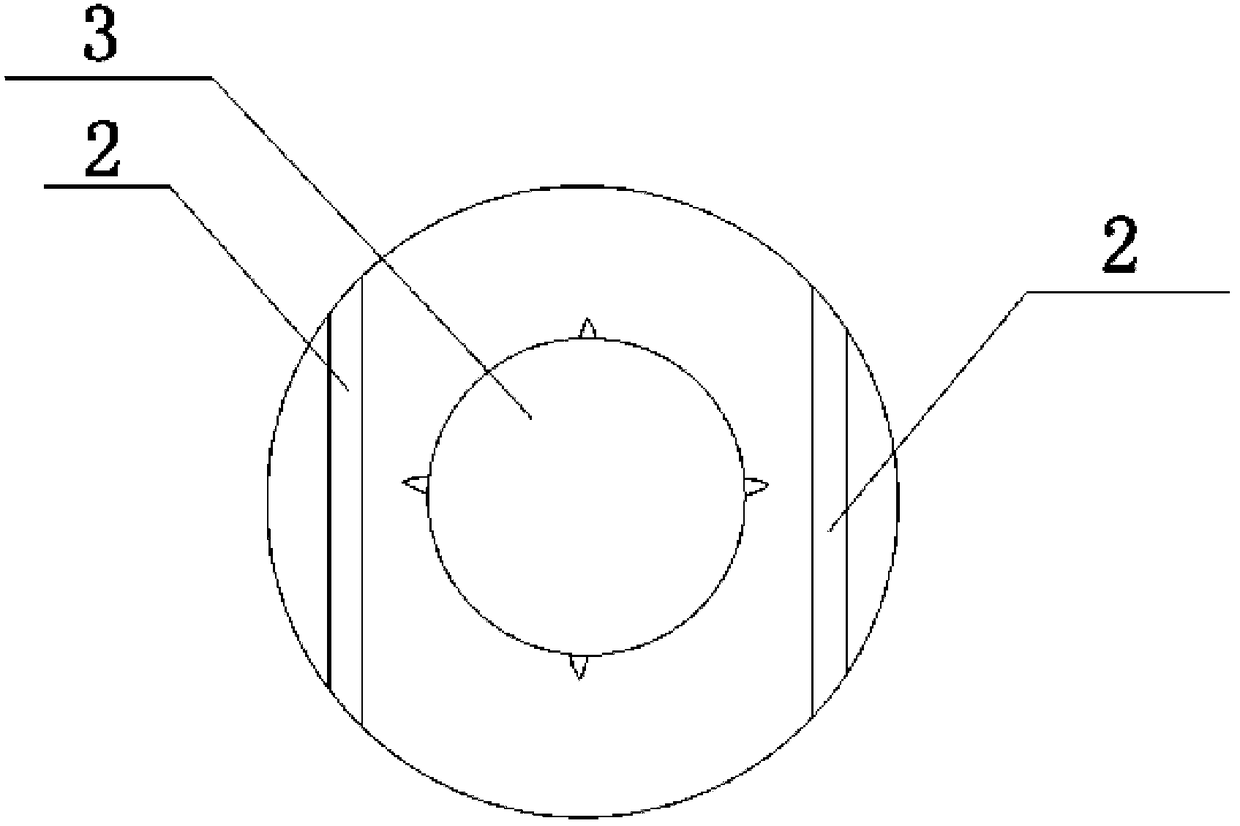

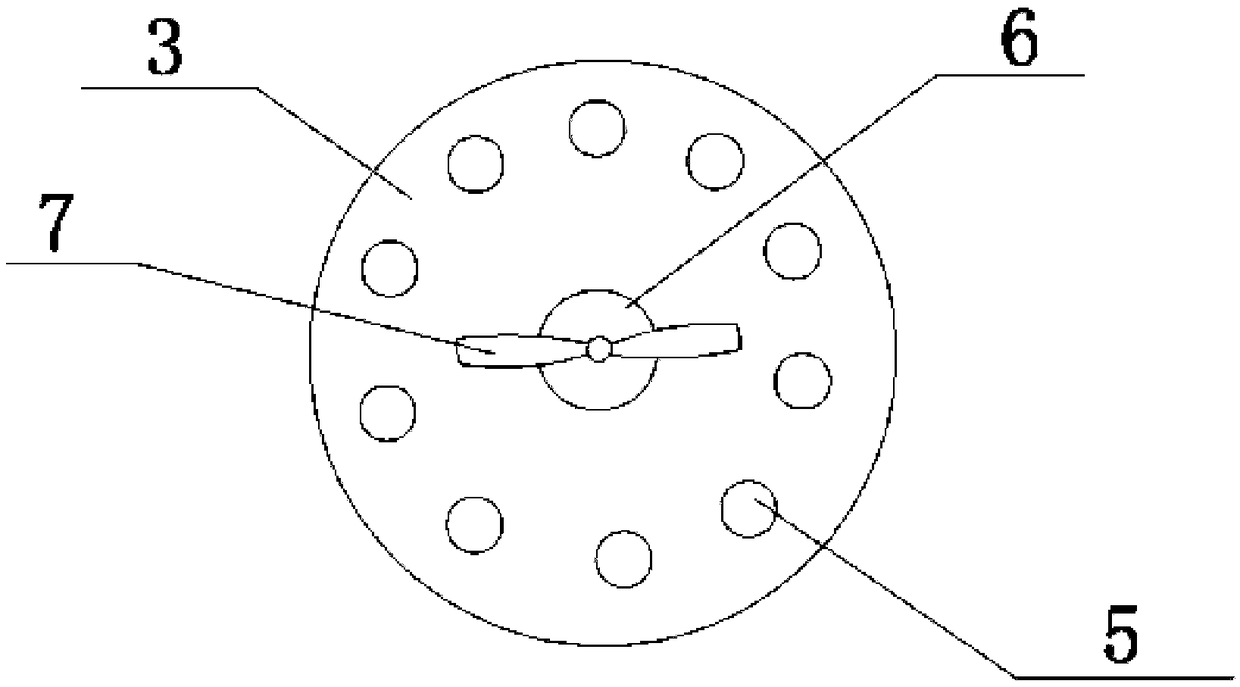

[0020] Such as Figure 1-5 The pumping device for a foundation pit shown includes a sand discharge chamber 1, which is in the shape of a circular platform, and the upper end surface of the sand discharge chamber 1 is larger than the lower end surface, and the upper end surface of the sand discharge chamber 1 is provided with two openings 2, two Two openings 2 are respectively located on both sides of the fixed box 3, the fixed box 3 is a cylindrical cavity structure, the lower end surface of the sand discharge chamber 1 is fixedly connected with the gravity block 4, and the center position of the upper end surface of the sand discharge chamber 1 is also connected with the fixed box 3, The upper end of the fixed box 3 protrudes from the upper surface of the sand discharge chamber 1, and the lower end of the fixed box 3 extends into the sand discharge chamber 1. The fixed box 3 is provided with several water flow channels 5 for water flow, and the water flow channels 5 are from t...

Embodiment 2

[0023] The difference between embodiment 1 and embodiment 2 is that the width of the opening 2 is 3 mm.

Embodiment 3

[0025] The difference between embodiment 1 and embodiment 3 is that the width of the opening 2 is 4mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com