Placement rack for flexible graphite ground wires

A flexible graphite and grounding wire technology, applied in the field of electrical equipment, can solve the problems of insufficient use effect and adaptability of the grounding wire storage rack, and achieve the effects of simple structure, strong practicability and convenient access.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

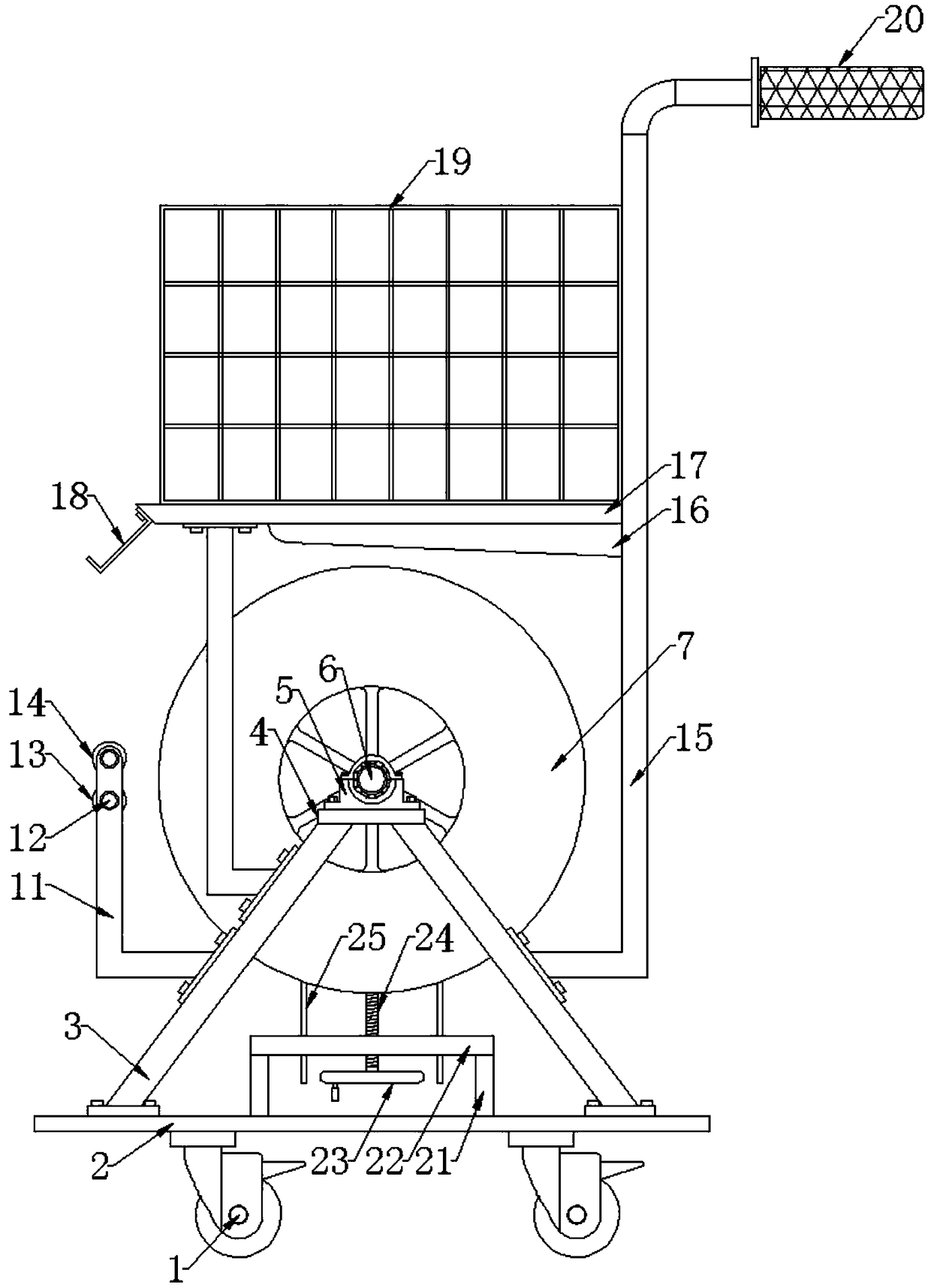

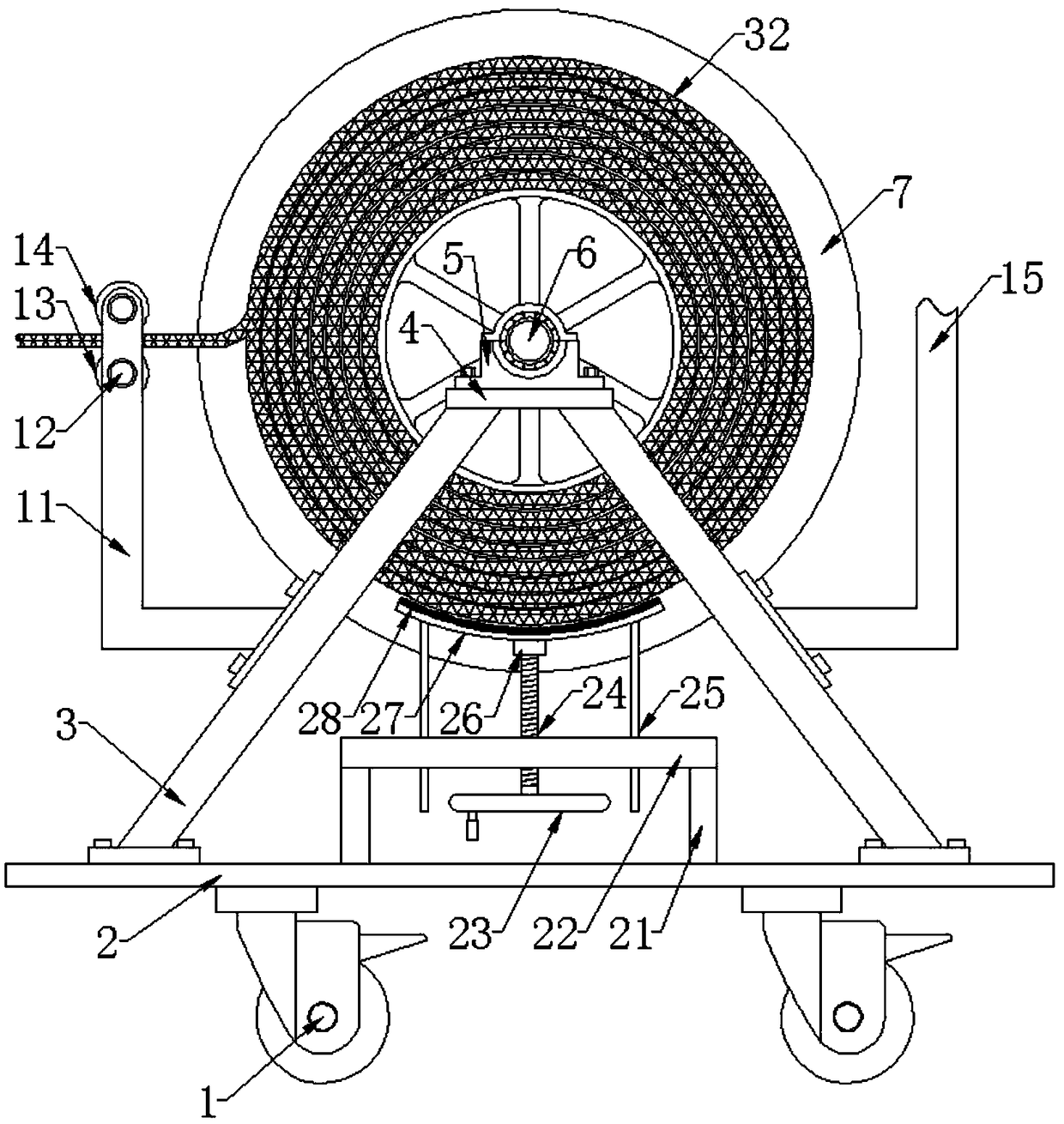

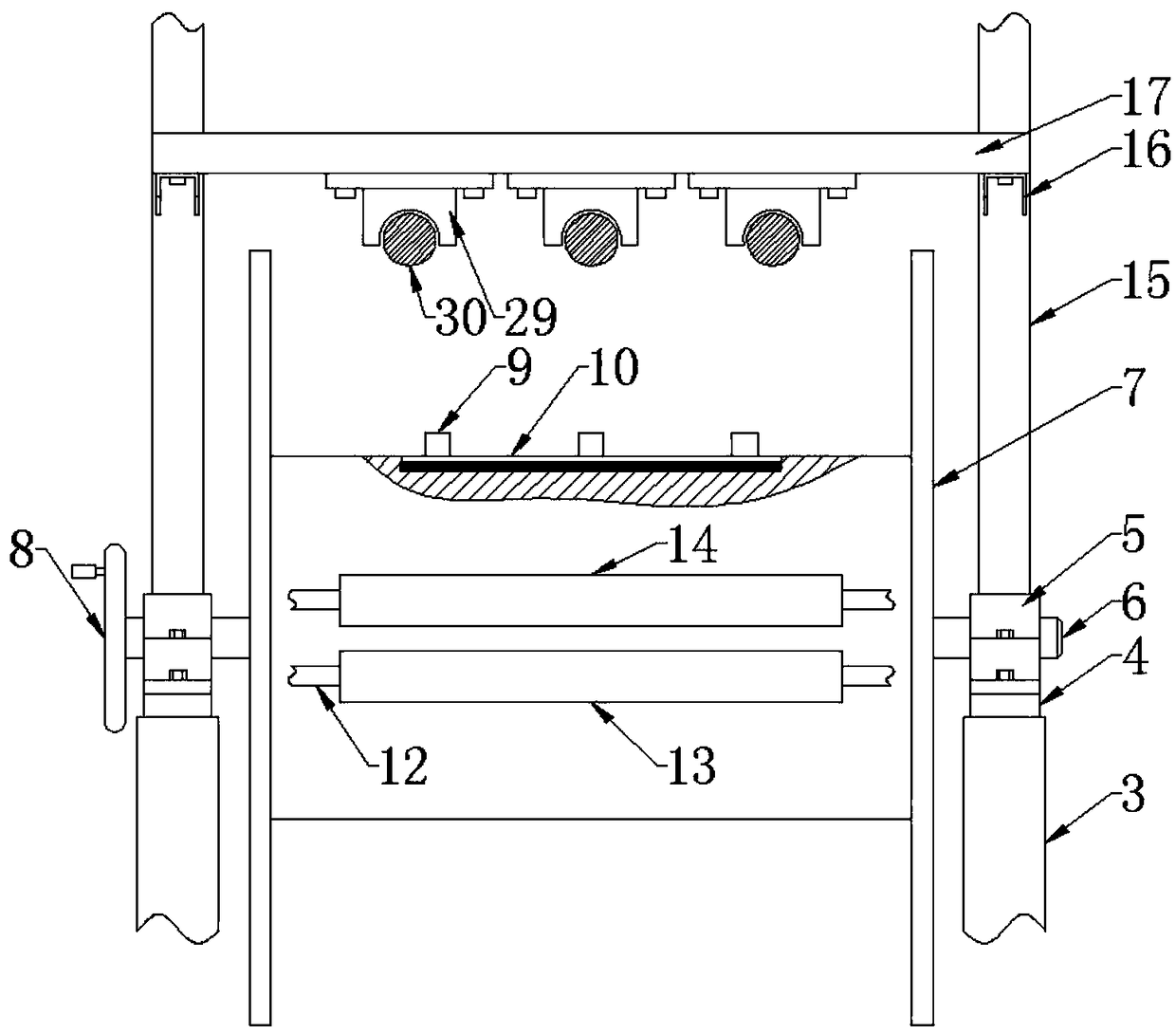

[0021] Such as Figure 1 to Figure 4 As shown, a placement frame for flexible graphite grounding wires includes a bottom plate 2 and a roller support frame 3, and the roller support frame 3 is symmetrically installed on the bottom plate 2 left and right, and the top of the roller support frame 3 is provided with a mounting plate -4, the mounting plate -4 is equipped with a bearing seat 5 through screws, the bearing seat 5 is provided with a roller bearing and a roller support shaft 6 is installed in rotation, and the left end of the roller support shaft 6 is provided with a hand wheel- 8. A roller 7 is fixedly installed on the roller support shaft 6, three pins 9 are arranged on the working surface of the roller 7 and a magnet 10 is arranged directly below it, and a vertical support is arranged directly below the roller 7 Plate 21 and horizontal support plate 22, described horizontal support plate 22 is installed on the upper end surface of base plate 2 by vertical support pla...

Embodiment 2

[0024] Such as Figure 1 to Figure 4 As shown, a placement frame for flexible graphite grounding wires includes a bottom plate 2 and a roller support frame 3, and the roller support frame 3 is symmetrically installed on the bottom plate 2 left and right, and the top of the roller support frame 3 is provided with a mounting plate -4, the mounting plate -4 is equipped with a bearing seat 5 through screws, the bearing seat 5 is provided with a roller bearing and a roller support shaft 6 is installed in rotation, and the left end of the roller support shaft 6 is provided with a hand wheel- 8. A roller 7 is fixedly installed on the roller support shaft 6, three pins 9 are arranged on the working surface of the roller 7 and a magnet 10 is arranged directly below it, and a vertical support is arranged directly below the roller 7 Plate 21 and horizontal support plate 22, described horizontal support plate 22 is installed on the upper end surface of base plate 2 by vertical support pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com