A metal positioning type cutting mechanism

A cutting mechanism and positioning technology, which is applied to metal processing equipment, shearing devices, cutters for shearing machines, etc. The effect of adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

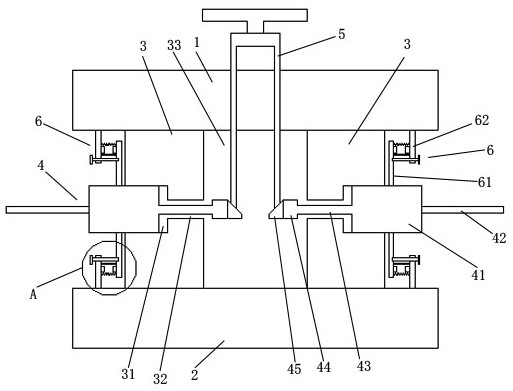

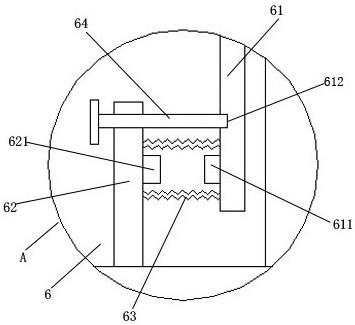

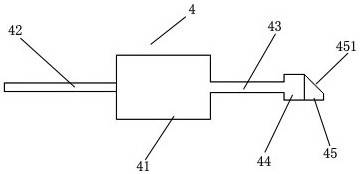

[0019] The content of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0020] Such as Figures 1 to 4 As shown, a metal positioning cutting mechanism includes an upper splint 1, a lower splint 2, a connecting ring 3, a driving column 5, a cutting assembly 4, and a pressing mechanism 6; the upper splint 1 and the lower splint 2 are parallel up and down respectively Setting; the connecting ring 3 is installed between the upper splint 1 and the lower splint 2; the inside of the connecting ring 3 is provided with a drive chamber 33; the surrounding of the connecting ring 3 is evenly provided with a plurality of telescopic grooves 31; The cutting assembly 4 includes a cutting knife 42, a telescopic block 41, and a drive rod 43; a telescopic block 41 is respectively radially telescopically installed in the telescopic slot 31 of the connecting ring 3; the outer side of the telescopic block 41 is installed with a cutting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com