Forged workpiece fixing device

A technology for fixing devices and workpieces, which is applied in the field of forging workpieces and can solve problems such as damage to the fixing devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

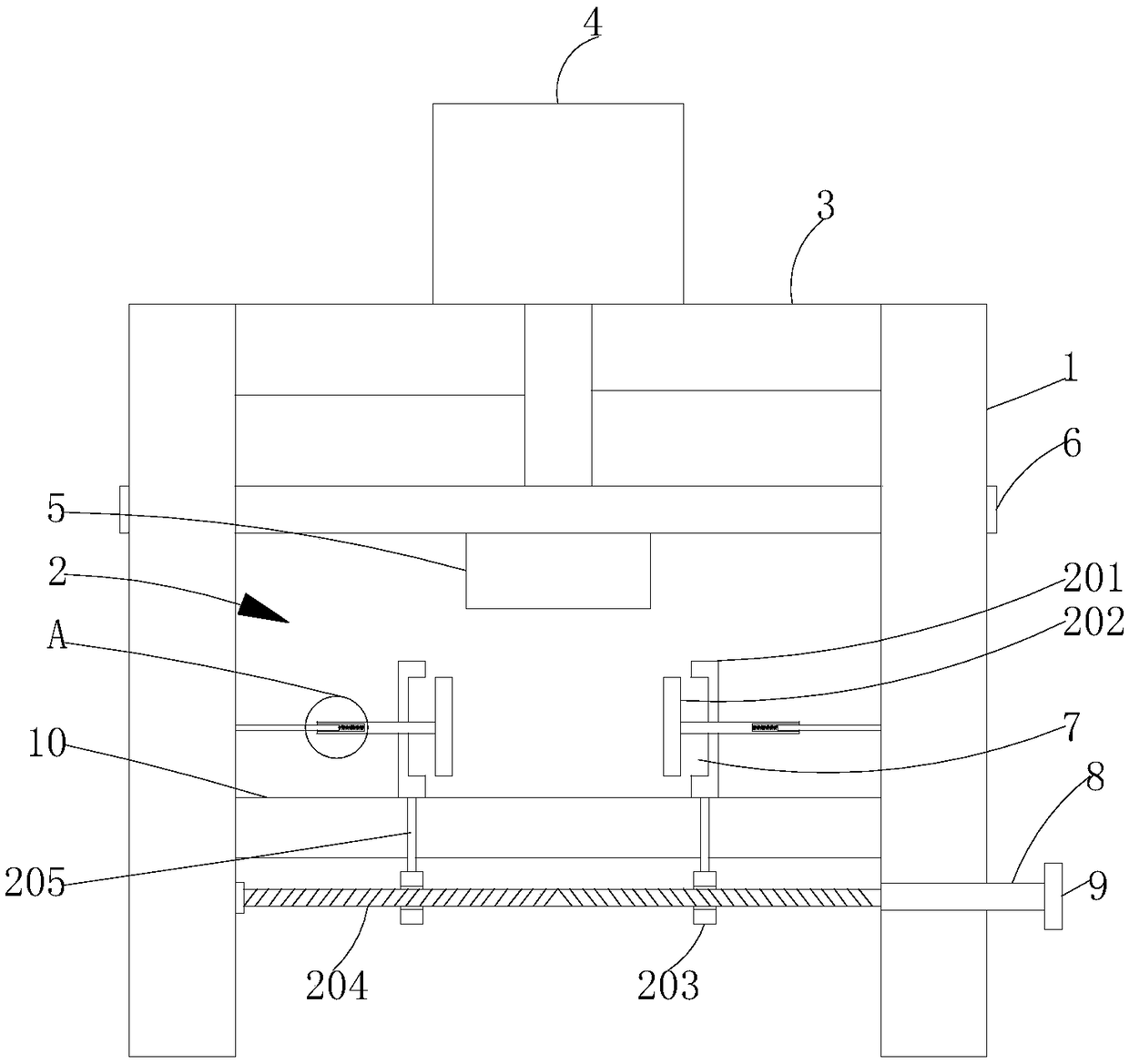

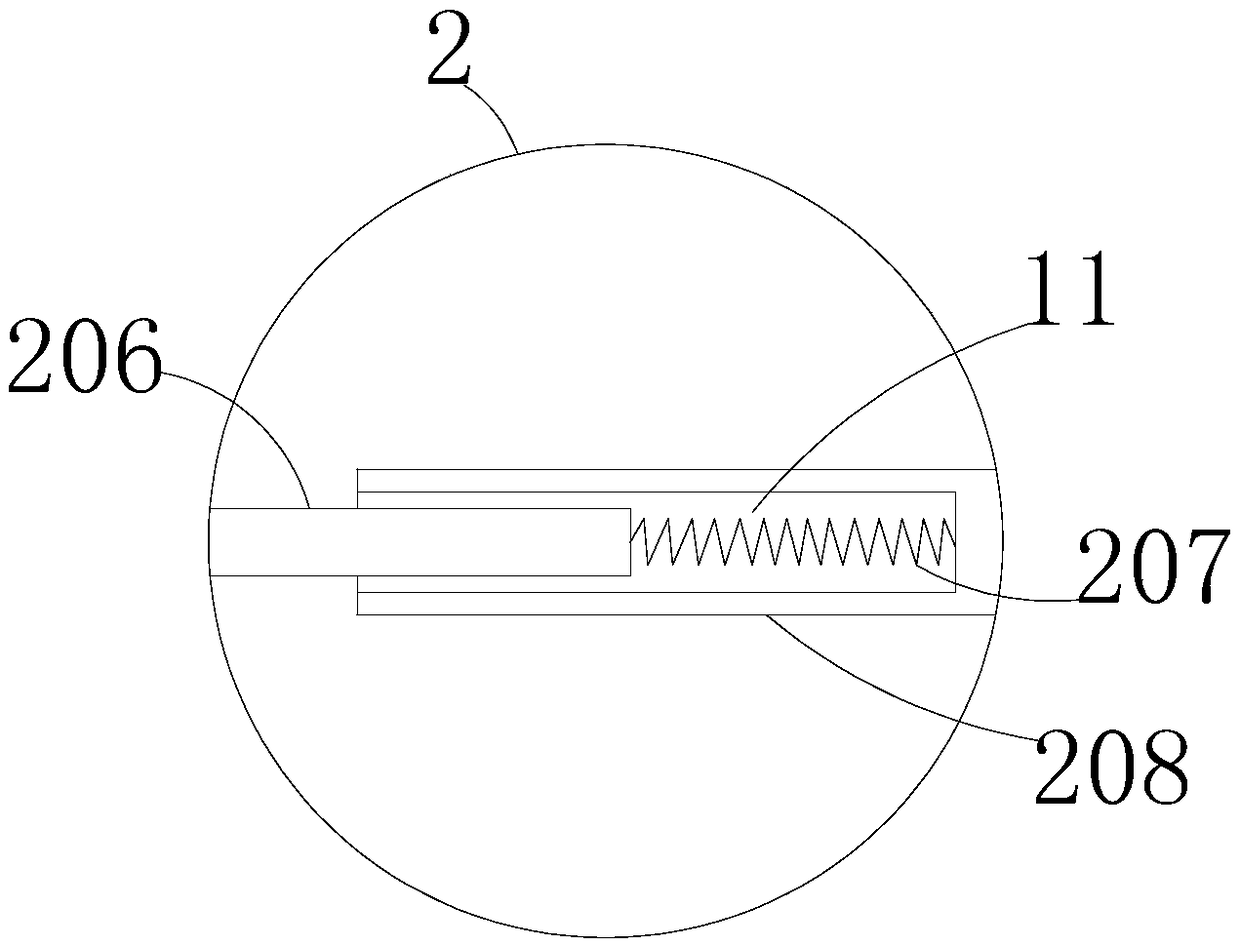

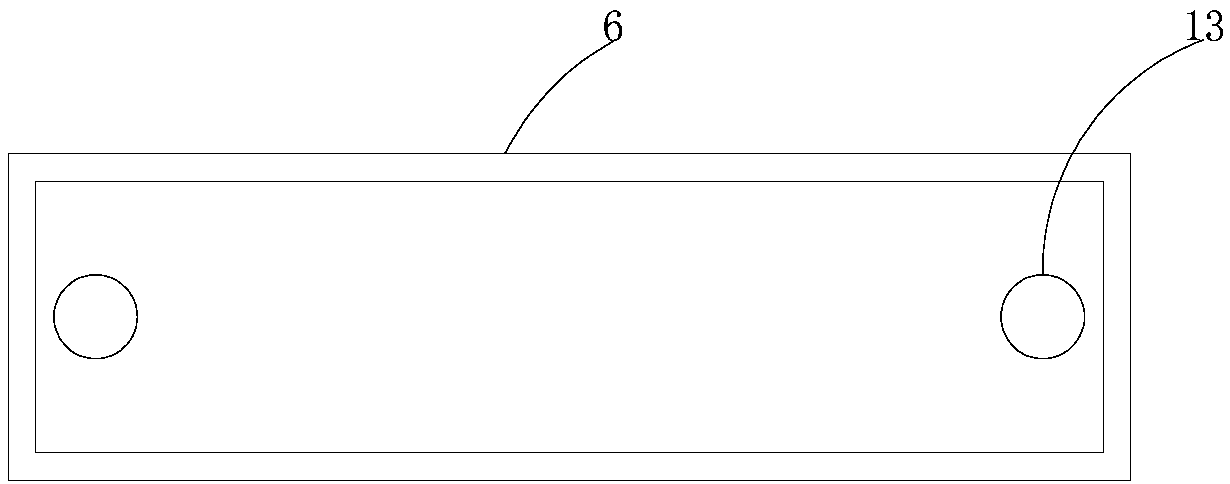

[0020] Such as Figure 1-5 As shown, the present invention provides a technical solution: a forging workpiece fixing device, including a pillar 1 and a fixing mechanism 2, and the fixing mechanism 2 includes a fixing block 1 201, a fixing block 2 202, a moving plate 203, a screw rod 204, and a connecting rod 205, fixed rod 206, spring 207 and movable rod 208, the number of pillars 1 is two, the two sides of two pillars 1 close to each other are respectively fixedly connected with the two sides of the workbench 10, and the top of the workbench 10 is provided with a long hole 12, The top of the workbench 10 is in contact with the bottom of the fixed block one 201, and the number of the fixed block one 201 is two. The side is provided with a recovery tank 7 that is compatible with the fixed block one 201, and the side of the fixed block two 202 close to the recovery tank 7 is fixedly connected with one end of the movable rod 208, and the other end of the movable rod 208 passes th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com