Energy-saving efficient impeller aerator

An aerator and impeller-type technology, which is applied in the field of fish farm aquaculture, can solve the problems of increasing the user's use cost, increasing the energy consumption of the motor, increasing the load of the motor, etc., and achieves the effects of improving fluidity, reducing energy consumption, and doing less work.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The technical solutions of the embodiments of the present invention will be clearly and completely described below in conjunction with the accompanying drawings of the present invention.

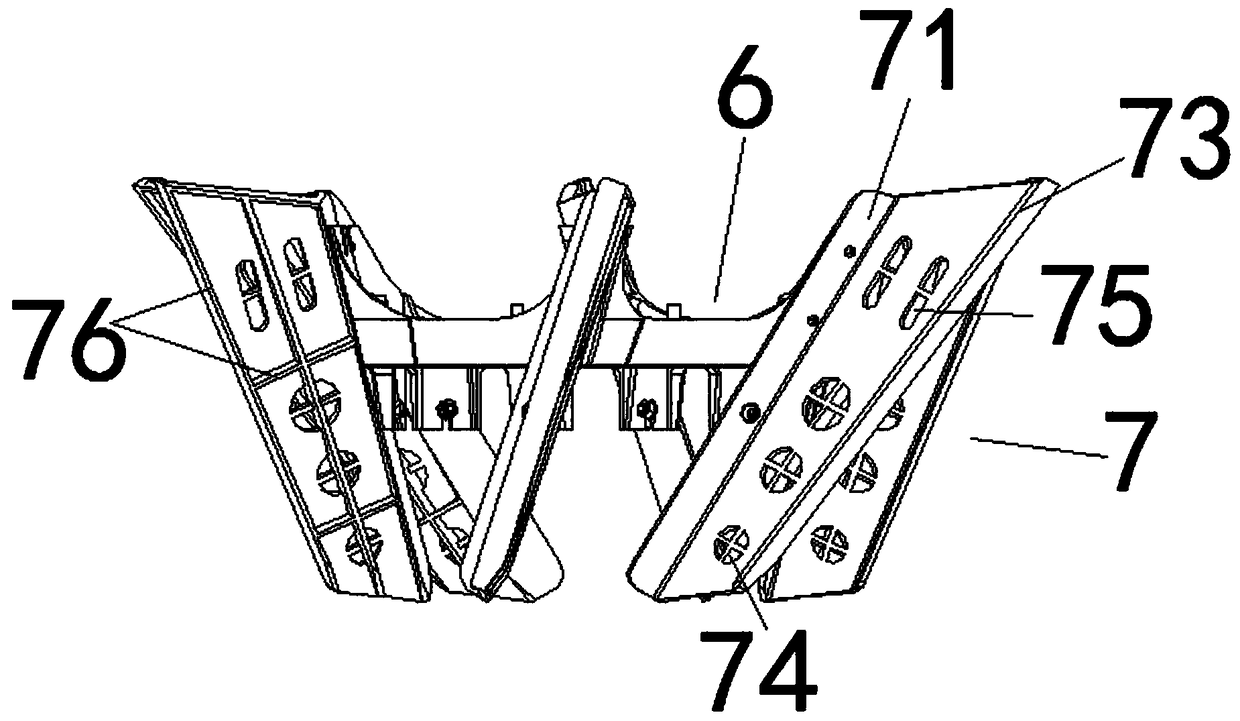

[0030] Such as Figure 1-10 As shown, an energy-saving and high-efficiency impeller-type aerator, the aerator 3 is fixed on the water surface through the support frame 1 and the buoy 2 to work, the aerator 3 includes: a motor 3, an impeller 5, the The impeller 5 is installed below the motor 3. The impeller 5 is composed of a central wheel body 6 and several detachable blades 7 distributed on the side of the wheel body 6. The blades 7 are installed obliquely on the side of the wheel body 6 through bolts. , and the position of the blade 7 can be adjusted up and down along the side of the wheel body 6, the angle between the installation position of the blade 7 and the axial direction of the wheel body 6 is an acute angle, and the angle between the blade 7 and the radial direction of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com