A device and method for preparing nanofiber/short fiber blended yarn

A nanofiber, blended yarn technology, applied in fiber processing, yarn, filament/thread forming, etc., can solve the problem of poor distribution uniformity of nanofibers, and achieve good distribution of nanofibers, improved uniformity, and avoid random deposition. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

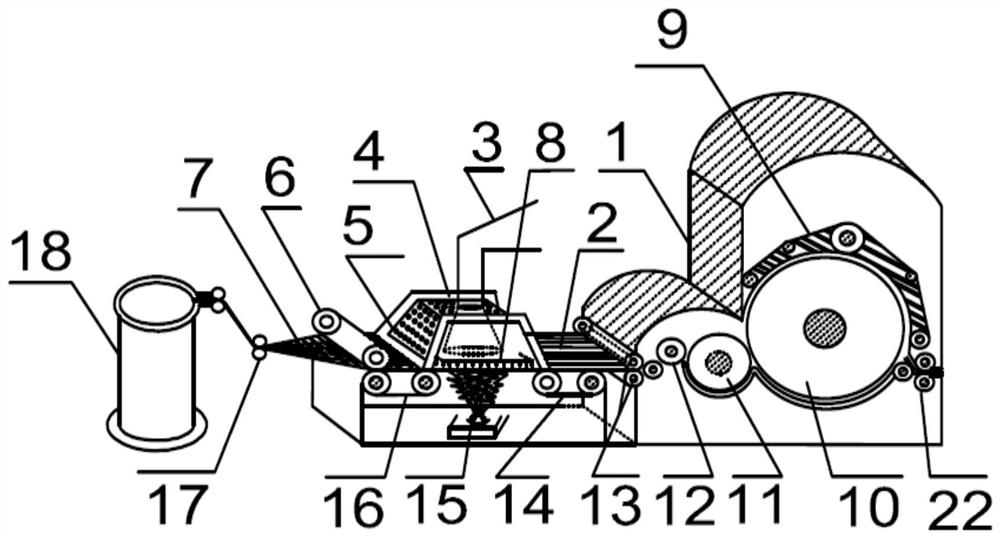

[0035] This embodiment provides a device for preparing nanofiber / staple blended yarn, such as figure 1 As shown, it specifically includes the following structures: carding machine 1, fiber web transfer device 4, electrospinning device 15, first conveyor belt 14 and second conveyor belt 16, second fiber web output roller 6, bell mouth 17, bar can 18. Nanofiber orientation induced deposition device 8;

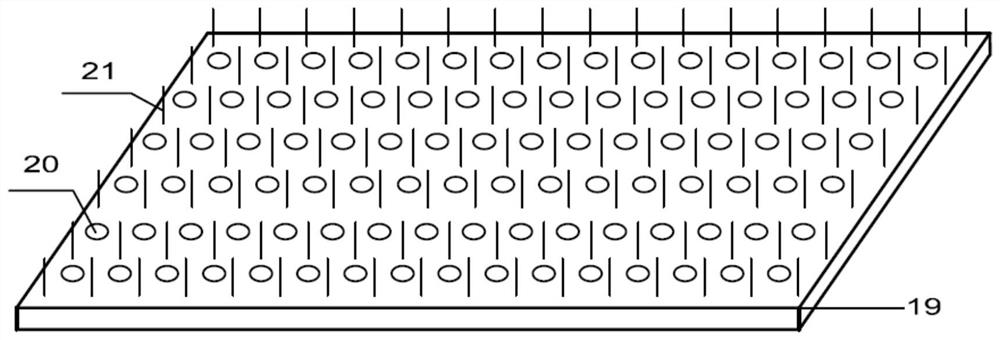

[0036] One side of the web transfer device 4 is connected to the carding machine 1 through the first transfer belt 14, and the other side of the web transfer device 4 is connected to the second web output roller 6 through the second transfer belt 16. The electrospinning The device 15 is arranged below the fiber web transfer device 4, the nanofiber orientation induced deposition device 8 is located inside the fiber web transfer device 4, and the nanofiber orientation induced deposition device 8 includes a pin plate 19 with air holes 20, Steel needles 21 are evenly distributed on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com