Connecting method and device of spinning machinery

A technology of jointing device and jointing method, which is applied in the field of jointing of spinning machinery and its device, and can solve problems such as jointing failure and yarn breakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

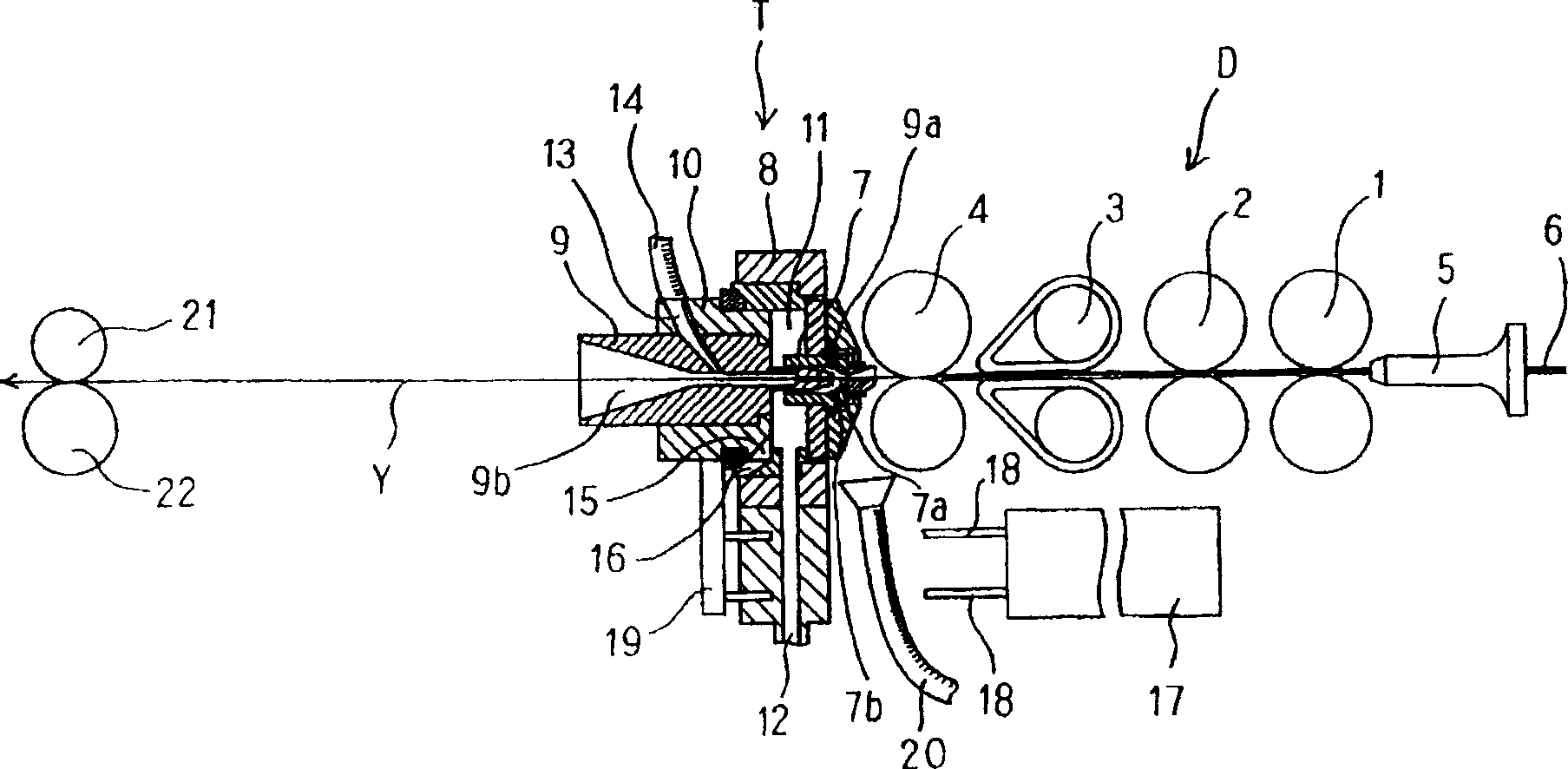

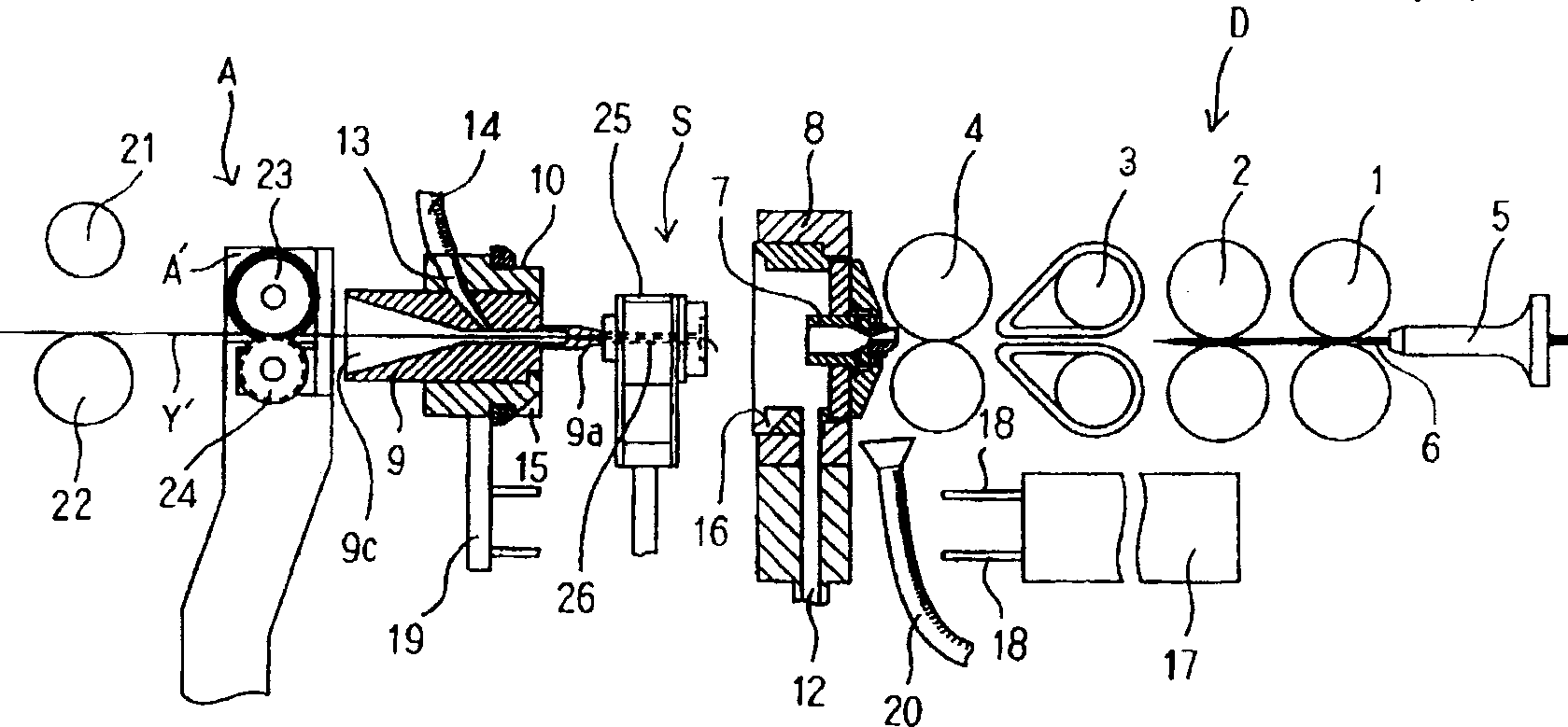

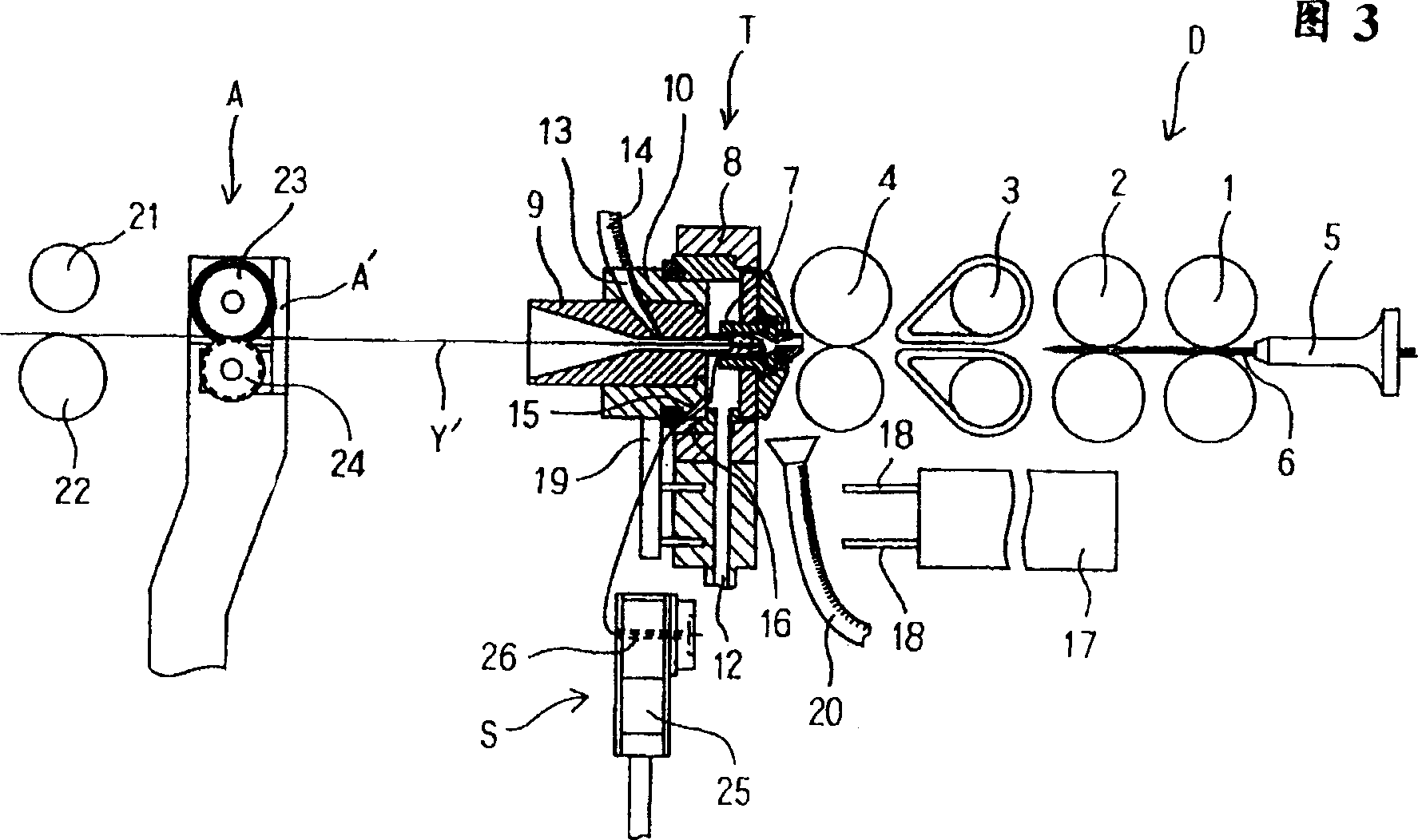

[0018] First, use figure 1 -6. The spinning machine as an example of the piecing method applied to the spinning machine will be described.

[0019] D is a traction device, and a traction device with four pairs of rollers is shown as an example. The traction device D is composed of four pairs of rollers, that is, a rear roller 1, a side roller 2, a middle roller 3 on which a dragon belt is erected, and a front roller 4. 5 is a creel, and the sliver 6 inserted into the creel 5 and supplied to the drawing device D is supplied to the drawing device D and stretched, and then supplied to the twisting device described below to form a yarn.

[0020] The twisting device T mainly includes: an air spinning nozzle 7 that forms a swirling airflow by jetting compressed air, a nozzle holder 8 that supports the nozzle, and a spindle with a through hole 9b that places its front end 9a inside the air spinning nozzle 9. (yarn guide tube) 9, and a support member 10 for supporting the spindle. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com